Method for producing low-sulfur gasoline

A technology for gasoline and gasoline fractions, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problem of not being able to completely suppress the regeneration of mercaptans, etc. The effect of no loss of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

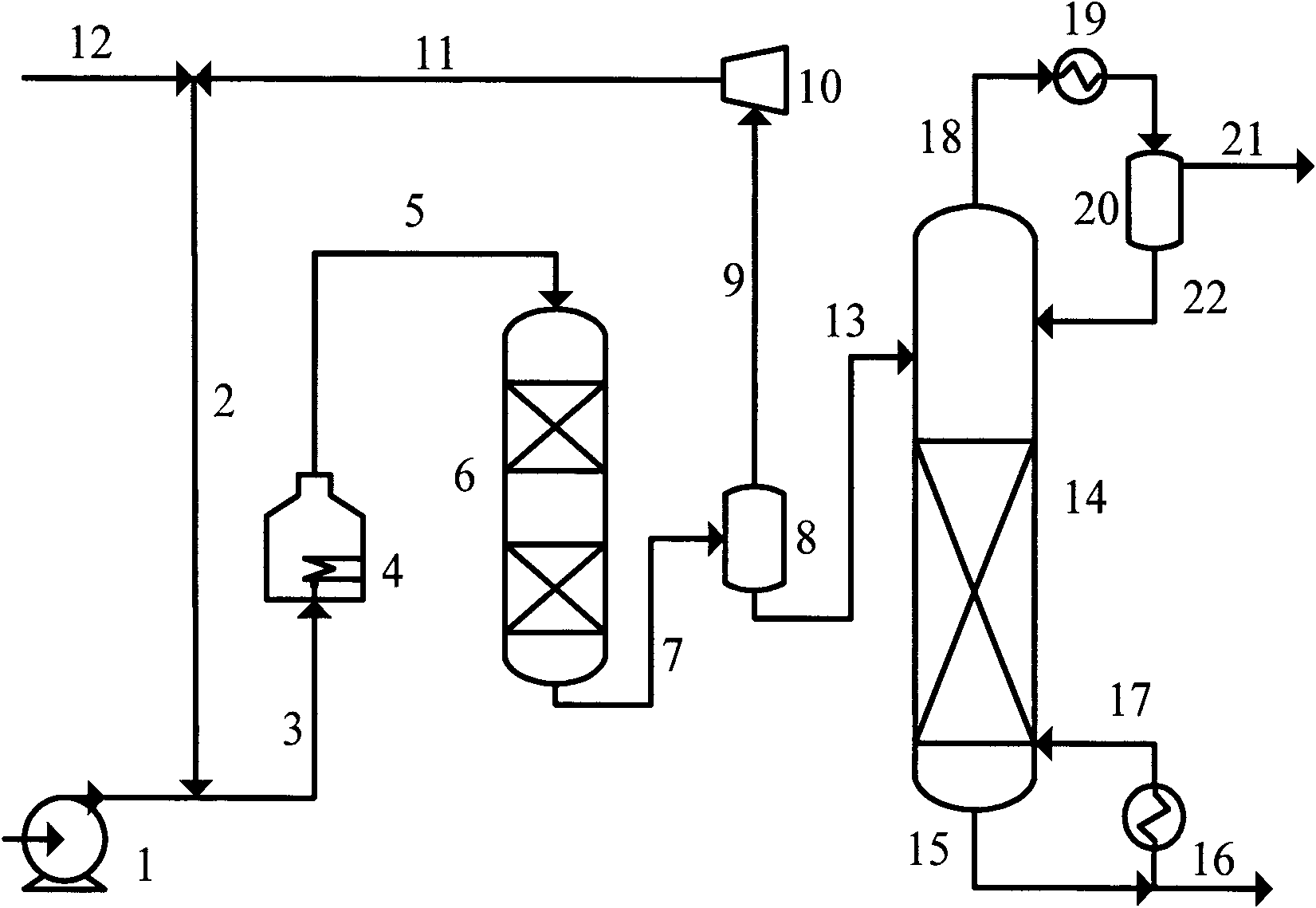

Image

Examples

Embodiment 1

[0034] (1) The hydrodesulfurization process of gasoline fraction is the same as that of Comparative Example 1.

[0035] (2) After the hydrogenation, the gasoline product 1 enters the stripping tower filled with the sweetening catalyst RSS-1A, and in the absence of hydrogen, catalytic sweetening is carried out. The operating pressure of the stripping tower is 0.8Mpa, and no stripping medium is added. The average temperature of the catalyst bed below the feed is 180° C., and the feed rate is 500 g / hour. The non-hydrodemercaptan product A1 is drawn from the bottom of the tower, and its properties are shown in Table 2.

[0036] The diameter of the stripping tower used for sulfur removal is Φ32mm and the height is 4m. Packing with a height of 1m above the feed inlet, and 0.5m high below the feed inlet, and sweetening catalyst RSS-1A in the bottom 2.5m of the stripping tower. The shape of the catalyst is a Φ3mm Raschig ring. The catalyst RSS-1A is produced by Sinopec Catalyst Chan...

Embodiment 2

[0051] (1) Same as Comparative Example 2, the fractional distillation of catalytic cracking full fraction gasoline is used to obtain gasoline light fraction and gasoline heavy fraction, and the cut point is 65°C. The cut gasoline light fraction is eluted with alkali to remove mercaptans.

[0052] (2) Same as in step (2) of Comparative Example 2, the gasoline heavy fraction is hydrodesulfurized to obtain the hydrodesulfurized gasoline heavy fraction.

[0053] (3) The heavy fraction of hydrodesulfurized gasoline enters the stripper filled with sweetening catalyst RSS-1A, and undergoes sweetening reaction in the absence of hydrogen to obtain sweetened gasoline heavy fraction A2, whose properties are shown in Table 3. The configuration of the stripper is the same as in Example 1. The operating pressure of the stripper is 1.3 MPa, the average temperature of the catalyst bed below the feed is 220° C., and the feed rate is 600 g / hour.

[0054] (4) The gasoline heavy fraction A2 aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com