Method for preparing sound absorption and heat insulation material and product thereof

A thermal insulation material and fiber technology, applied in the direction of melt spinning, textile and paper making, final product manufacturing, etc., can solve the problems of high melting point of PBT and inability to meet high temperature melt blown spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

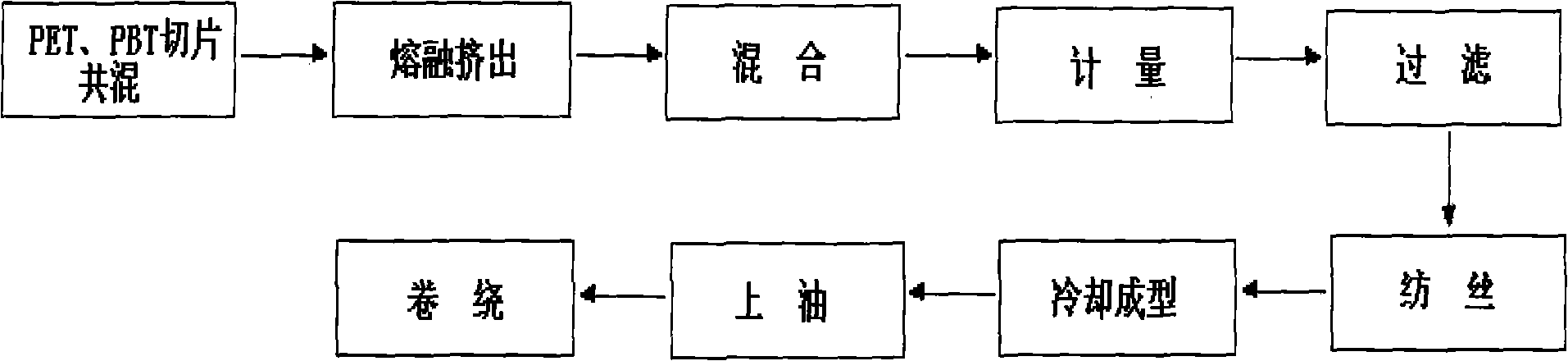

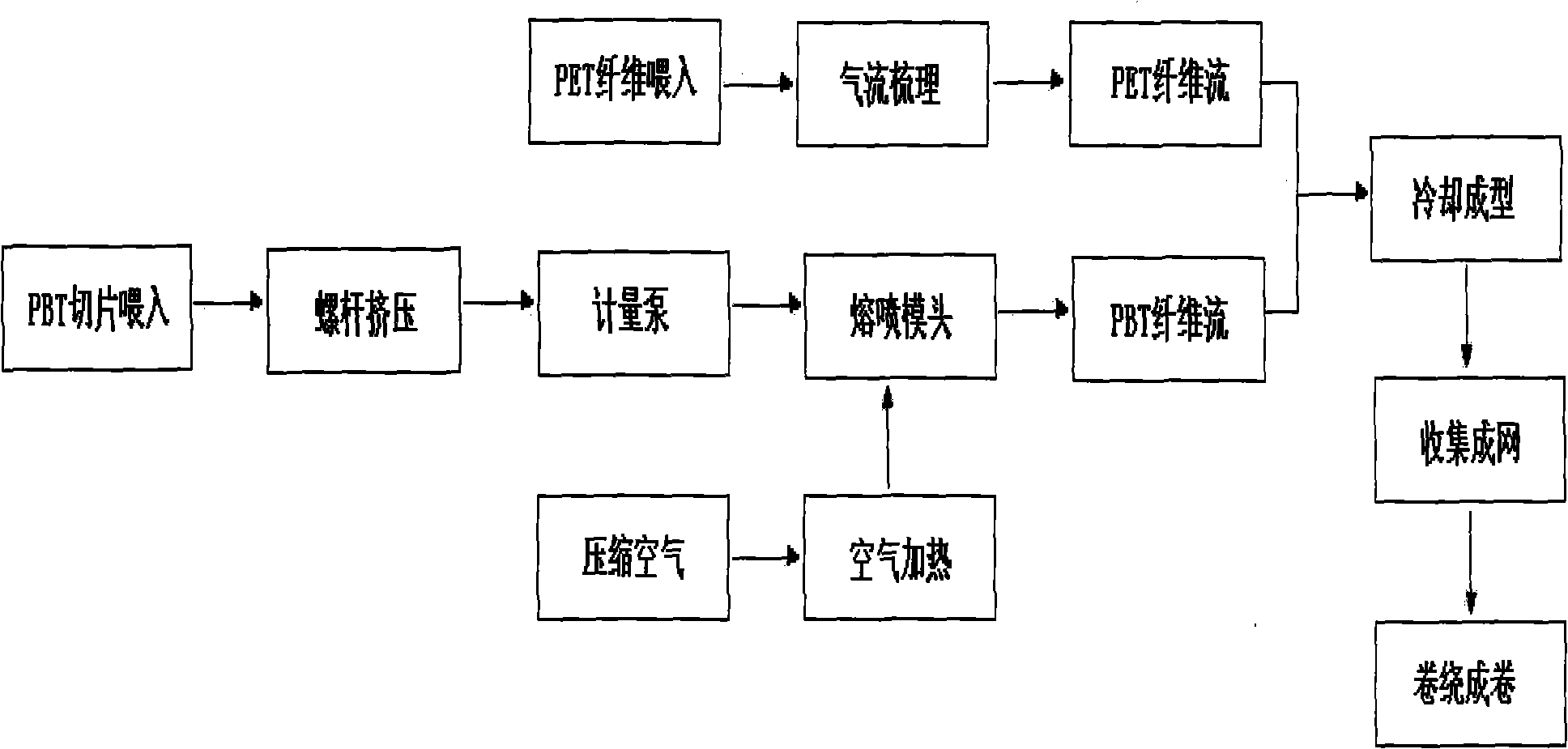

[0022] The preparation process of the sound-absorbing and heat-insulating material designed by the present invention (participated in figure 2 ), is a mixed fiber web material made of PET carded fiber and PBT melt-blown superfine fiber. The material is fluffy, has high porosity, small specific flow resistance, large air permeability, and more energy absorbed by sound waves; and due to the existence of PBT melt-blown ultra-fine fibers, the surface area of fibers increases, and the chance of contact between sound waves and fibers Increase, the consumption of sound energy increases; at the same time, PBT fiber also has good heat resistance. The material is bonded and formed by waste heat of PBT melt-blown fibers, which maintains the original characteristics of PET and PBT fibers without using any adhesive, which simplifies the process and is conducive to environmental protection. This preparation method also increases the designability and industrial feasibility of the materi...

Embodiment 1

[0026] A PET / PBT two-component sound-absorbing and heat-insulating material with a mass ratio of 35:65 was prepared.

[0027] (1).Preparation of PET carding fiber flow: the PET fiber is metered and fed into the air carding machine by a known method, and after the PET fiber is air carded, an orderly PET carding fiber flow is formed; the average fineness of the PET fiber is 7dtex, and the average fiber length 40mm;

[0028] (2).Preparation of PBT ultra-fine melt-blown fiber flow: Feed PBT raw materials into the screw extruder and melt at 290°C. The extruded melt is transported to the metering pump through the pre-filter, and passed through the metering pump After metering, it is transported to the spinneret die, and hot air at 310°C is added to both sides of the spinneret hole to stretch the PBT fibers to form a melt-blown PBT fiber flow;

[0029](3). Prepare two-component sound-absorbing and heat-insulating materials: adjust the delivery rate of PET fiber flow (or adjust the m...

Embodiment 2

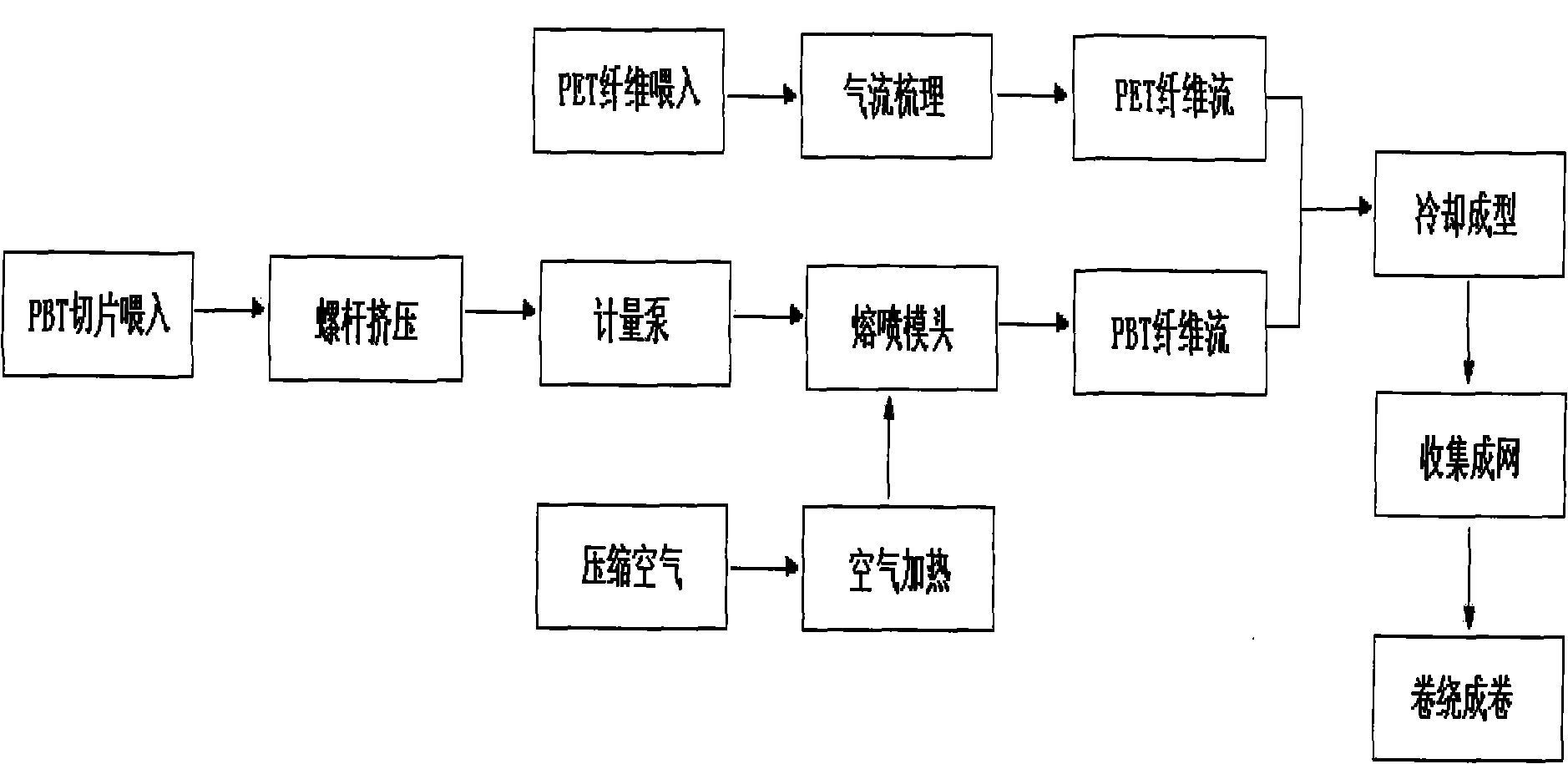

[0032] A 40:60 PET / PBT two-component sound-absorbing and heat-insulating material was prepared.

[0033] (1). Preparation of PET carding fiber flow: PET fiber is metered and fed into air carding machine with known method, PET fiber forms orderly PET carding fiber flow after air carding; the average denier of PET fiber is 10dtex, and fiber average length is 75mm;

[0034] (2).Preparation of PBT ultra-fine melt-blown fiber flow: Feed PBT raw materials into the screw extruder and melt at 310°C. The extruded melt is transported to the metering pump through the pre-filter, and passed through the metering pump After metering, it is transported to the spinneret die, and hot air at 320°C is added to both sides of the spinneret hole to stretch the PBT fibers to form a flow of melt-blown PBT fibers;

[0035] (3). Preparation of two-component sound-absorbing and heat-insulating materials: adjust the delivery rate of PET fiber flow (or adjust the melt-blown PBT metering pump), so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com