High-efficiency energy-saving bulb

A high-efficiency energy-saving, bulb technology, applied in lighting and heating equipment, irradiation, deodorization, etc., can solve problems such as air pollution, dizziness, discomfort, etc., to reduce damage and improve life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

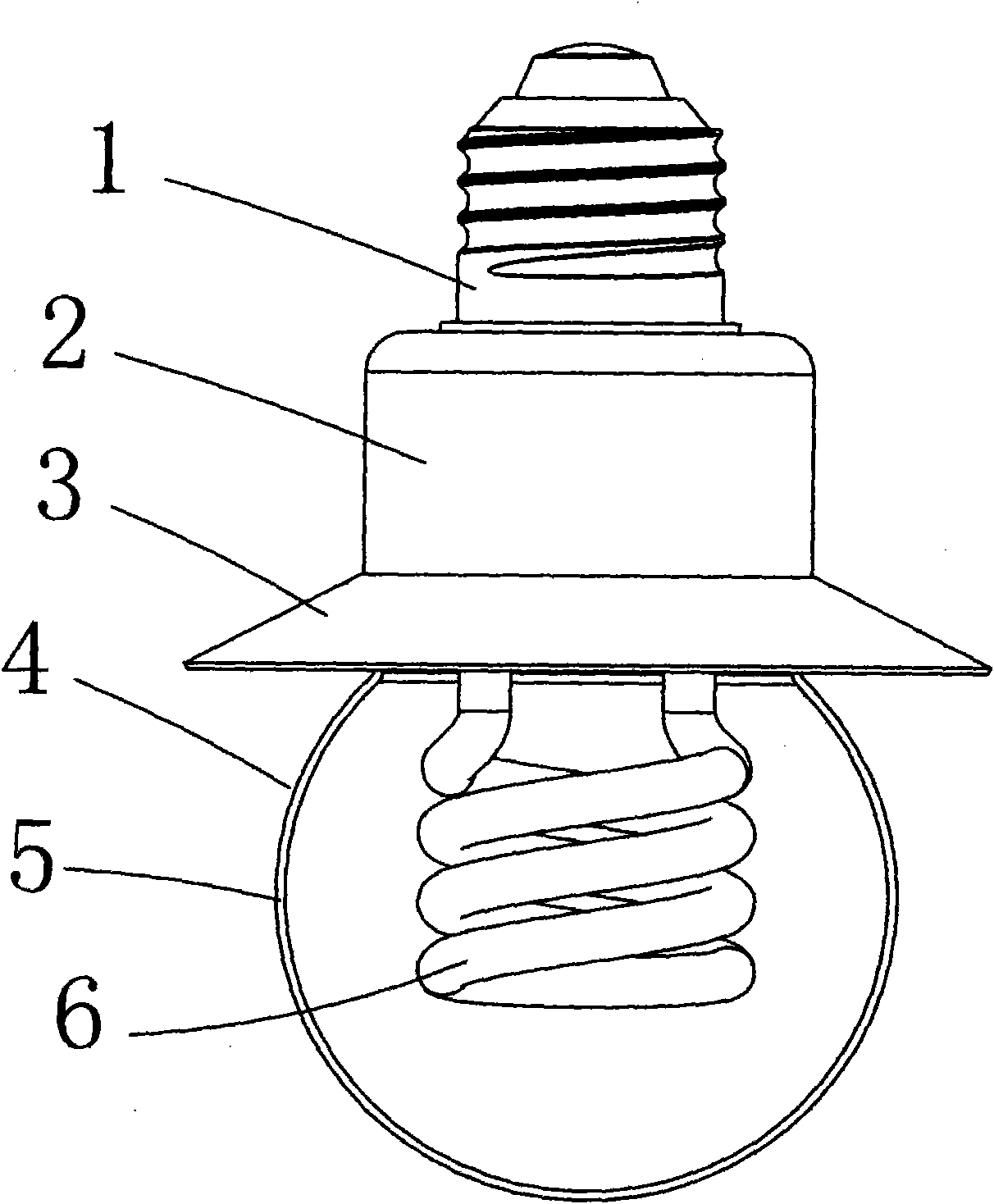

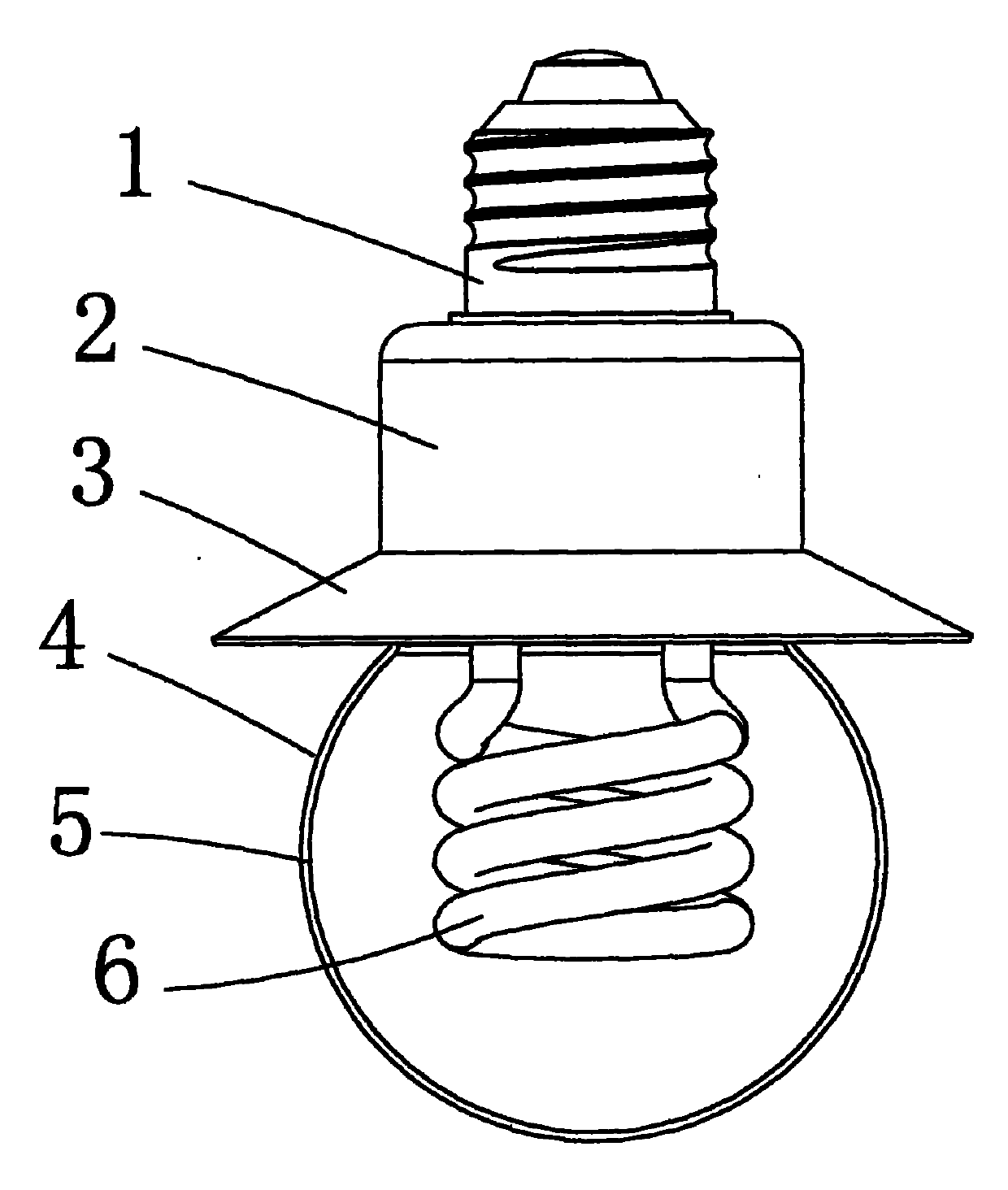

[0014] Such as figure 1 As shown, a high-efficiency energy-saving bulb 6 is provided. The difference is that the lamp tube uses a single-tap high-efficiency U-shaped and spiral energy-saving lamp tube 5 and a secondary optical glass dome cover 4 with a photocatalyst installed on the outside, which is buckled on the plastic shell for nanometer reflection. The cover 3 can achieve 3 to 5 times the luminous efficiency of the lamp tube through the improvement of the above three structures.

[0015] Such as figure 1 As shown, a glass dome cover 4 is used outside the U-shaped and spiral energy-saving lamp tubes to perform secondary optical treatment on the primary light emitted by the U-shaped and spiral energy-saving lamp tubes to achieve uniform light efficiency. The glass dome cover 4, the surface of the glass dome cover 4 is coated with a material through a special coating process, and after secondary optical treatment, it can reach a high light transmittance of 90%, and achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com