Novel middle-temperature carbonyl sulfide hydrolysis method

A carbonyl sulfide, medium temperature technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of precious metal oxides, complicated catalyst preparation, short service life, etc., and achieve high cost, long service life, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

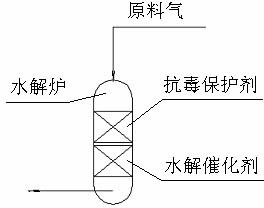

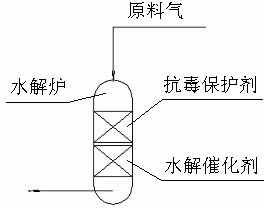

Image

Examples

Embodiment 1

[0023] Laboratory example, carried out in a glass reactor, the condition is that the diameter of the reaction tube: 30mm, the total filling volume: 30mL, the anti-toxic protective agent is above the hydrolysis catalyst, the volume ratio of the anti-toxic protective agent to the hydrolysis catalyst is 1:2, two kinds Catalyst particle size: diameter of 4.0 ~ 5.0mm original particle sample, normal pressure, space velocity 2500h -1 , raw gas composition (volume percent): H 2 50%, CO 10%, CO 2 26%, O 2 0.5%, H 2 S 6000ppm, COS 40ppm, the balance is water vapor, reaction temperature: 250°C, reaction time: 240h, the raw material gas passes through the anti-toxic protective agent and hydrolysis catalyst in turn, and the COS content at the outlet is measured as the expression of its reactivity. The test results are shown in Table 1.

Embodiment 2

[0025] Laboratory example, carried out in a glass reactor, the condition is that the diameter of the reaction tube: 30mm, the total filling volume: 30mL, the anti-toxic protective agent is above the hydrolysis catalyst, the volume ratio of the anti-toxic protective agent to the hydrolysis catalyst is 1:4, two kinds Catalyst particle size: diameter of 4.0 ~ 5.0mm original particle sample, normal pressure, space velocity 2500h -1 , raw gas composition (volume percent): H 2 50%, CO 10%, CO 2 26%, O 2 0.5%, H 2S 6000ppm, COS 40ppm, the balance is water vapor, reaction temperature: 250°C, reaction time: 240h, the raw material gas passes through the anti-toxic protective agent and hydrolysis catalyst in turn, and the COS content at the outlet is measured as the expression of its reactivity. The test results are shown in Table 1.

Embodiment 3

[0027] Laboratory example, carried out in a glass reactor, the condition is that the diameter of the reaction tube: 30mm, the total filling volume: 30mL, the anti-toxic protective agent is above the hydrolysis catalyst, the volume ratio of the anti-toxic protective agent to the hydrolysis catalyst is 1:6.5, two kinds Catalyst particle size: diameter of 4.0 ~ 5.0mm original particle sample, normal pressure, space velocity 2500h -1 , raw gas composition (volume percent): H 2 50%, CO 10%, CO 2 26%, O 2 0.5%, H 2 S 6000ppm, COS 40ppm, the balance is water vapor, reaction temperature: 250°C, reaction time: 240h, the raw material gas passes through the anti-toxic protective agent and hydrolysis catalyst in turn, and the COS content at the outlet is measured as the expression of its reactivity. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com