Method for controlling large-scale nodular iron cast coagulation tissue

A technology of solidification structure and control method, which is applied in the field of control of solidification structure of large ductile iron castings, and can solve problems such as difficult quality control, coarse grains, and graphite distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

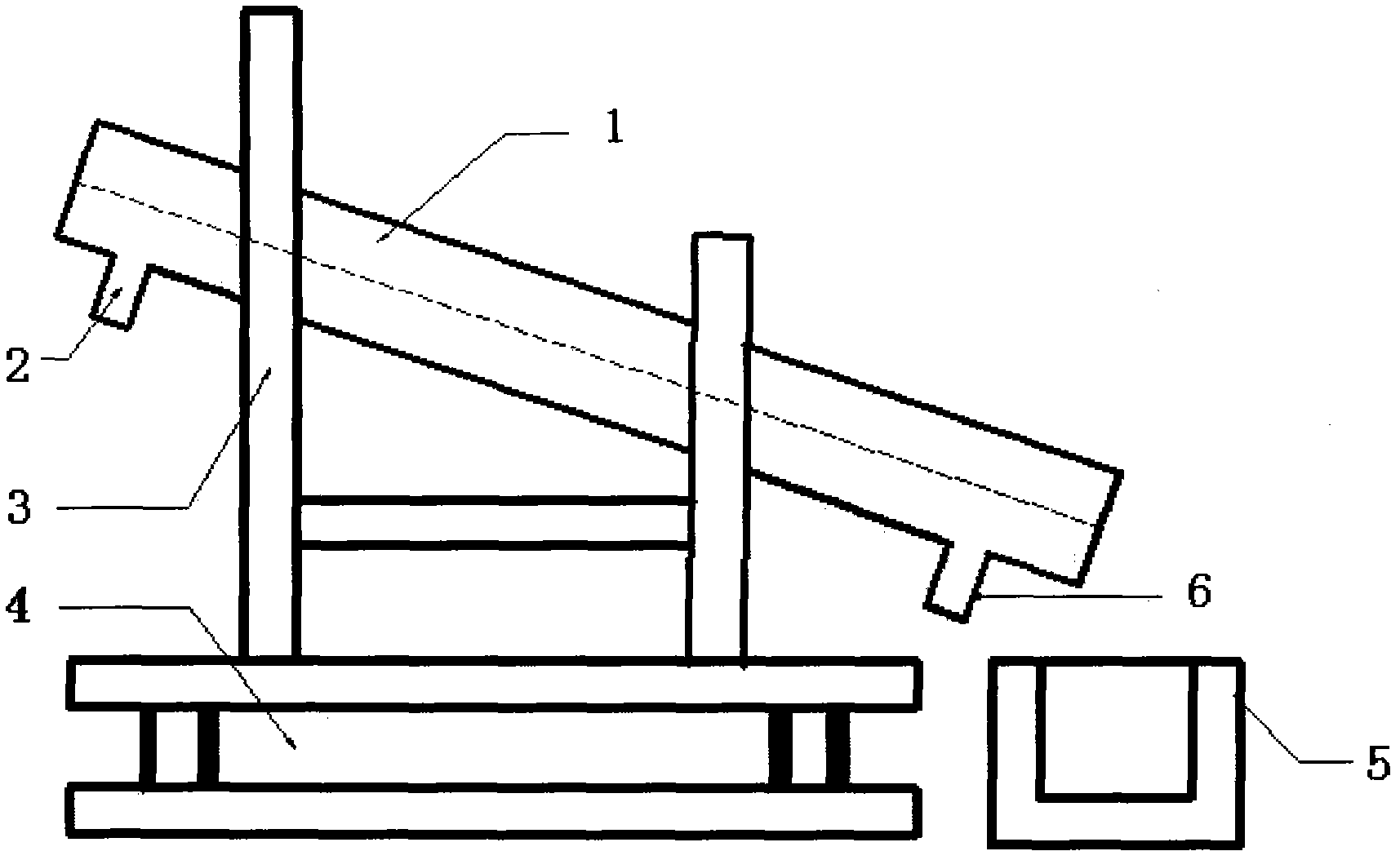

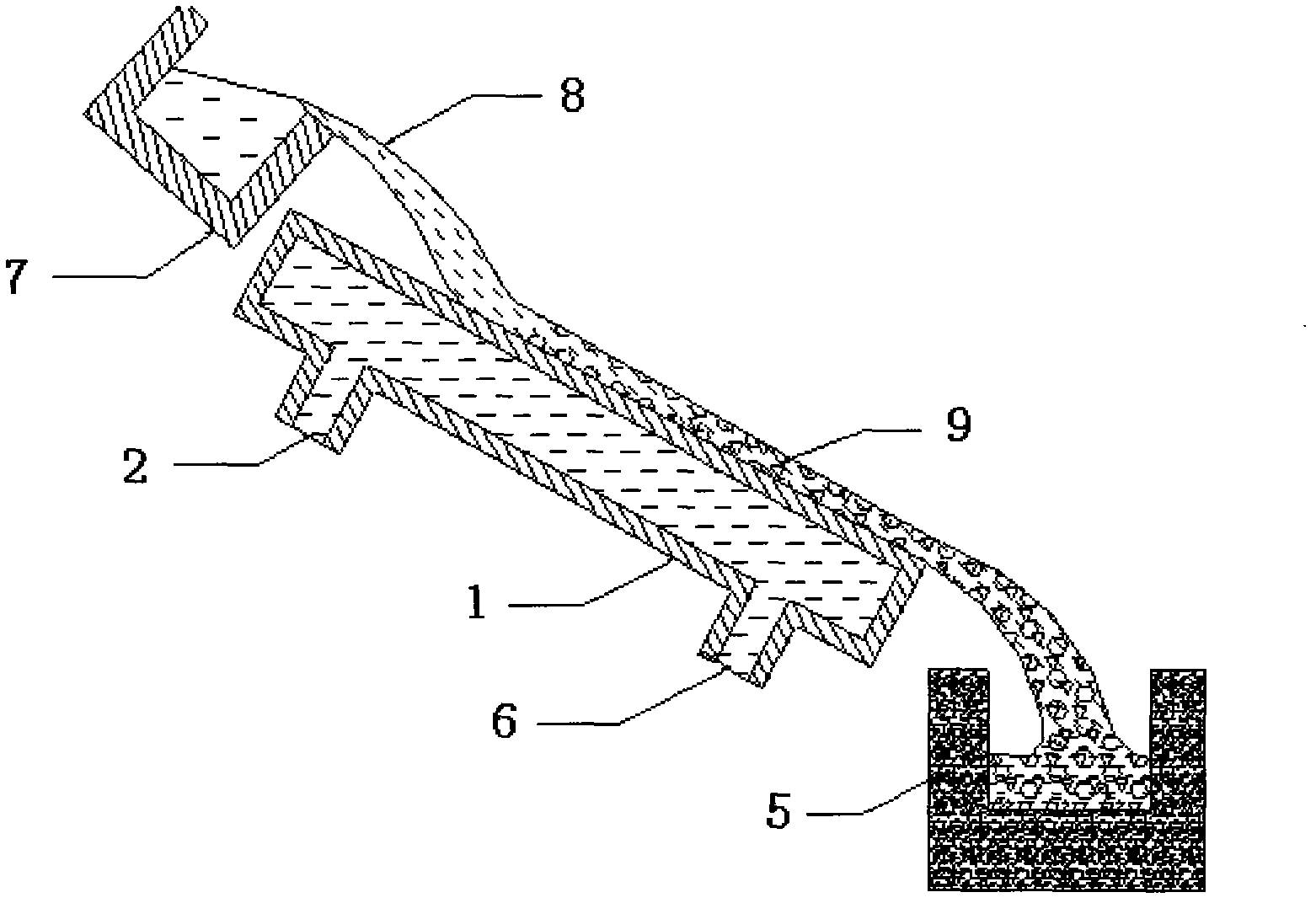

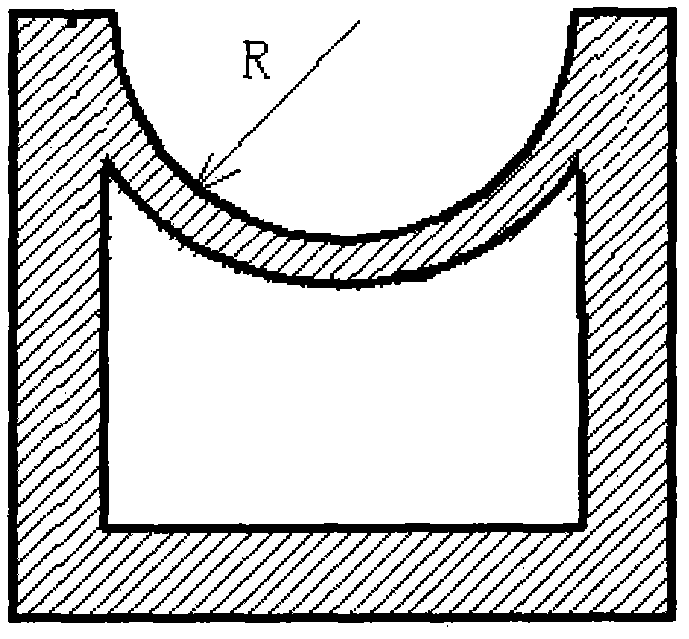

[0016] Cast a large ductile iron test piece with a diameter of 600mm and a height of 500mm, and the weight of the test piece is about 1 ton. According to the method of the present invention, use such as figure 1 , figure 2 For the cooling body shown, the radius of curvature is selected as 200mm according to the weight of the casting. During casting, the temperature before the molten iron contacts the cooling body is controlled at 1349.8 degrees Celsius according to the formula (1350-casting tonnage / 5); after it flows through the cooling body with a length of 1000mm and an inclination angle of 30°, its temperature drops to the formula (1300 - Casting tonnage / 5) limited 1299.8 degrees Celsius (the temperature at which molten iron flows out of the cooling body can be controlled by adjusting the water flow in the cooling body), then poured into the mold, and obtained a large ductile iron test block after solidification. After dissection, coagulated tissue analysis was performed...

Embodiment 2

[0018] Casting the large-scale nodular cast iron parts of maximum thermal joint size 500mm, weight 30 tons, according to the method of the present invention, according to casting weight, select radius of curvature to be 300mm, inclination angle 30 °, the cooling body that length is 1000mm. During casting, the temperature before the molten iron contacts the cooling body is controlled at 1344 degrees Celsius according to the formula (1350-casting tons / 5); after flowing through the cooling body, the temperature drops to 1294 degrees Celsius limited by the formula (1300-casting tons / 5), Then pour into the mold, and after solidification, large ductile iron castings are obtained. The nesting material in the center of the hot section is analyzed for solidification structure. The results show that, compared with the large ductile iron castings obtained by pouring directly into the mold at 1294 degrees Celsius without cooling, the nodularization rate is increased from 71% to 79%, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com