Method for synthesizing iron diacetone

A technology for the synthesis of iron acetylacetonate, which is applied to the preparation of aldehyde/ketone chelates, etc., can solve the problems of high equipment requirements, low yield, and many synthesis steps, and achieve low solvent consumption, high purity, and product selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

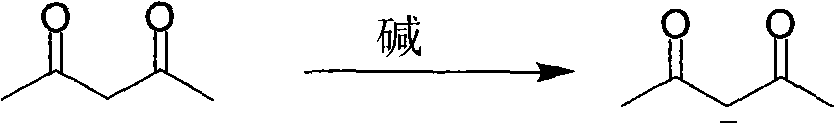

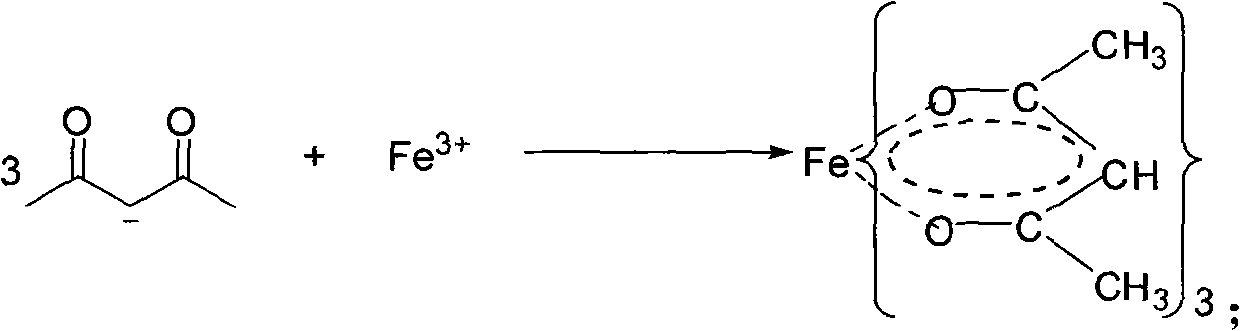

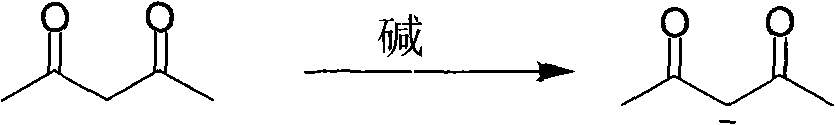

Method used

Image

Examples

Embodiment 1

[0021] Put 1.68g (30mmol) KOH and 3.00g (30mmol) acetylacetone into a mortar, grind for 10min, make it fully mixed, add 2.70g (10mmol) FeCl 3 ·6H 2 O, grind for 30 min, add 15 mL of deionized water, filter with suction, wash 3 times with 30 mL of deionized water, and dry at 75°C for 3 h to obtain a crude product. The crude product was recrystallized with acetone, and the acetone was recycled to obtain 3.06 g of the product with a yield of 86.7%. The melting point of the product was 180-182°C.

Embodiment 2

[0023] Put 1.20g (30mmol) NaOH, 3.00g (30mmol) acetylacetone into the mortar, grind for 10min, make it fully mixed, add 2.70g (10mmol) FeCl 3 ·6H 2 O, grind for 60 min, add 15 mL of deionized water, filter with suction, wash twice with 20 mL of deionized water, and dry at 75°C for 2.5 h to obtain a crude product. The crude product was recrystallized with absolute ethanol, and the ethanol was recycled to obtain 3.08 g of the product with a yield of 87.3%. The melting point of the product was 179-182°C.

Embodiment 3

[0025] Put 1.68g (30mmol) KOH and 4.00g (40mmol) acetylacetone into a mortar, grind for 10min, make it fully mixed, add 2.70g (10mmol) FeCl 3 ·6H 2 O, grind for 30 minutes, add 15 mL of deionized water, filter with suction, wash twice with 20 mL of deionized water, and dry at 60°C for 2.5 hours to obtain a crude product. The crude product was recrystallized with acetone, and the acetone was recycled to obtain 3.19 g of the product with a yield of 90.4%. The melting point of the product was 179-182°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com