Method for improving quality of industrial N-methylpyrrolidone

A technology for methyl pyrrolidone and methyl pyrrolidone is applied in the field of improving the quality of industrial grade N-methyl pyrrolidone, can solve the problems of high risk, difficult process control and high input cost, and achieves convenient operation process, stable product quality and high cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

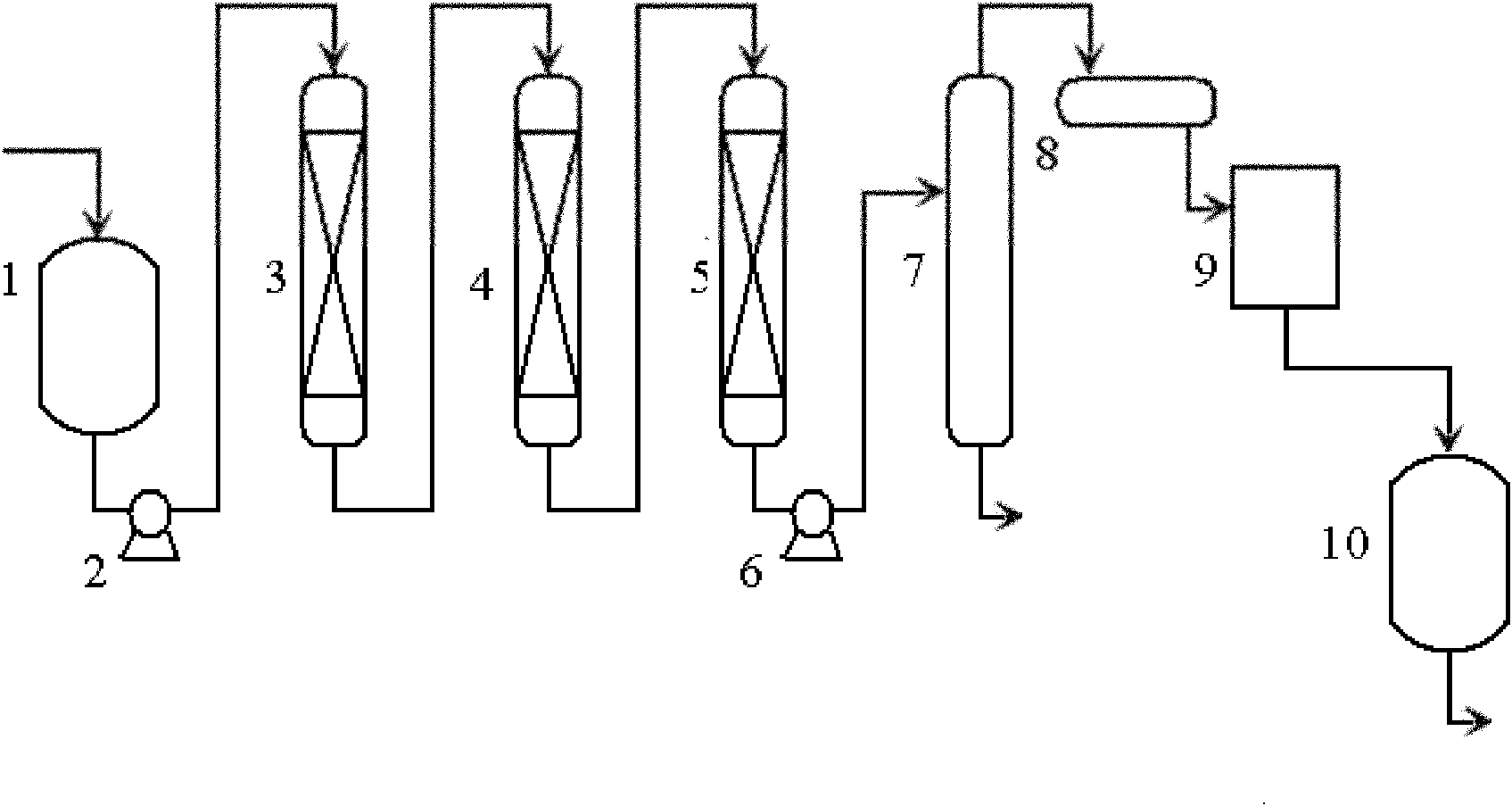

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Pretreatment of macroporous adsorption resin, strongly acidic cation exchange resin and strongly basic anion exchange resin.

[0024] 1) Pretreatment of macroporous adsorption resin: use organic alcohol solvents (such as ethanol, isopropanol, etc.) to soak and rinse the adsorption resin until the organic alcohol at the rinse outlet of the resin does not become turbid after adding water, and then use high-purity Ionized water rinses the adsorbent resin until the TOC of the rinsed water is less than 5.

[0025] 2) Pretreatment of strongly acidic cation exchange resin: after transforming the cation exchange resin into H-type, wash the cation exchange resin with high-purity water until the conductivity of the resin washing water is 1-10 μS / cm.

[0026] 3) Pre-treatment of strongly basic anion exchange resin: After transforming the anion exchange resin into OH type, wash the anion exchange resin with high-purity water until the conductivity of the resin washing water...

Embodiment 2

[0032] The macroporous adsorption resin, strongly acidic cation exchange resin and strongly basic anion exchange resin were pretreated, and the adsorption resin was soaked and rinsed with organic alcohol solvent isopropanol, and the rest of the steps were the same as in Example 1.

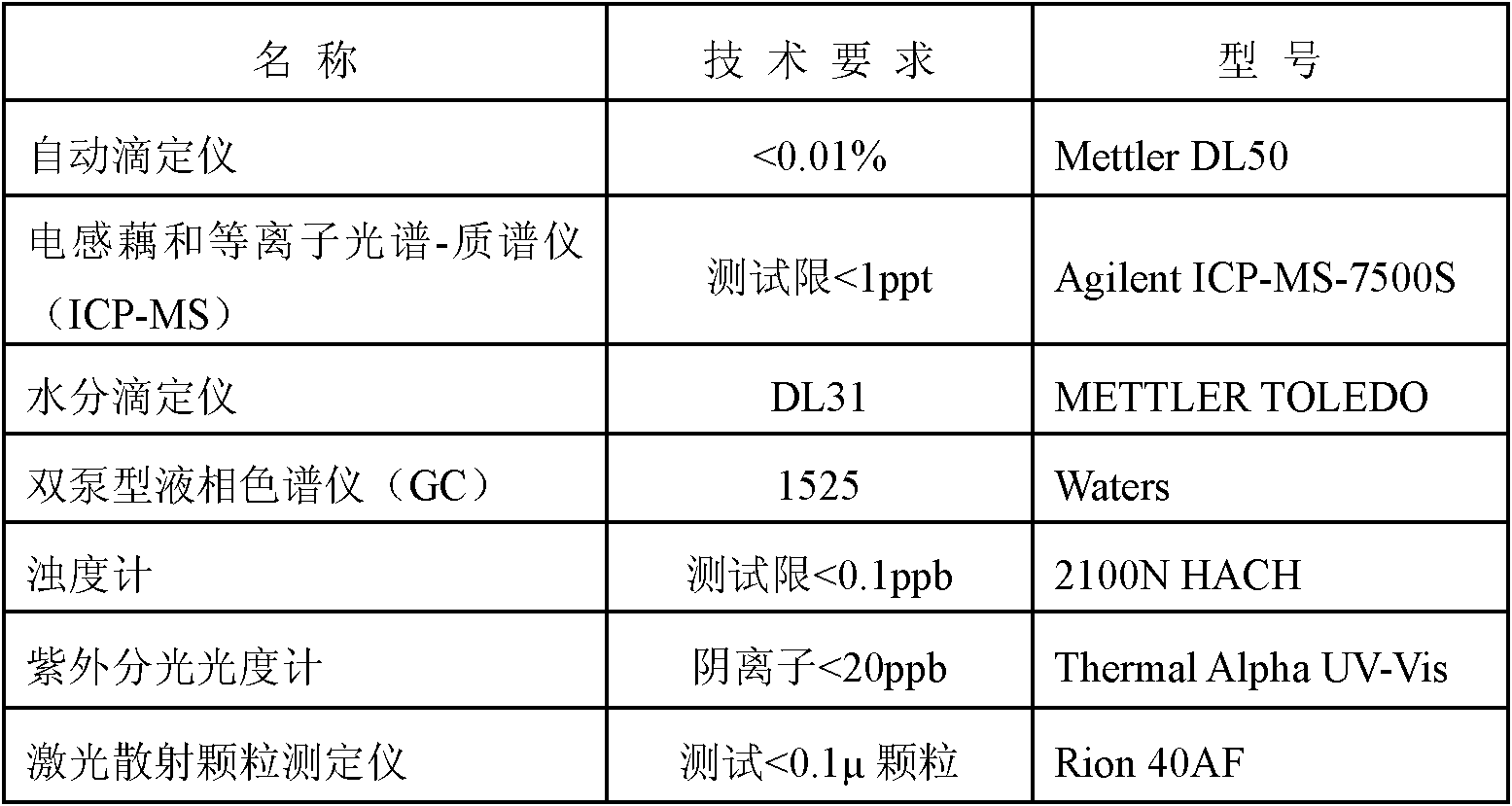

[0033] The standard and analysis result of table 1N-methylpyrrolidone

[0034] project

unit

SEMI C8 standard

Example 1

Example 2

NMP content

wt%

99.80

99.82

99.89

Exterior

APHA

≤30

15

17

Water content (H 2 O)

%

≤0.03

0.015

0.013

Free amine (as CH 3 NH 2 )

ppm

≤5

3

3

Chloride (Cl)

ppb

≤300

119

117

Nitrate (NO 3 )

ppb

≤400

230

255

Phosphate (PO 4 )

ppb

≤250

111

114

Sulfate (SO 4 )

ppb

≤250

125

122

Aluminum (Al)

ppb

≤5

0.02

0.02

Ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com