Vacuum shock protection method for process of feeding gas into ion source cavity

An ion source and vacuum technology, which is applied in the field of vacuum chamber gas supply and vacuum shock protection, can solve problems affecting the service life of vacuum pumps and ion sources, destroying high vacuum of ion sources, and vacuum chamber impact, etc., to achieve easy operation, Simple operation, eliminate impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

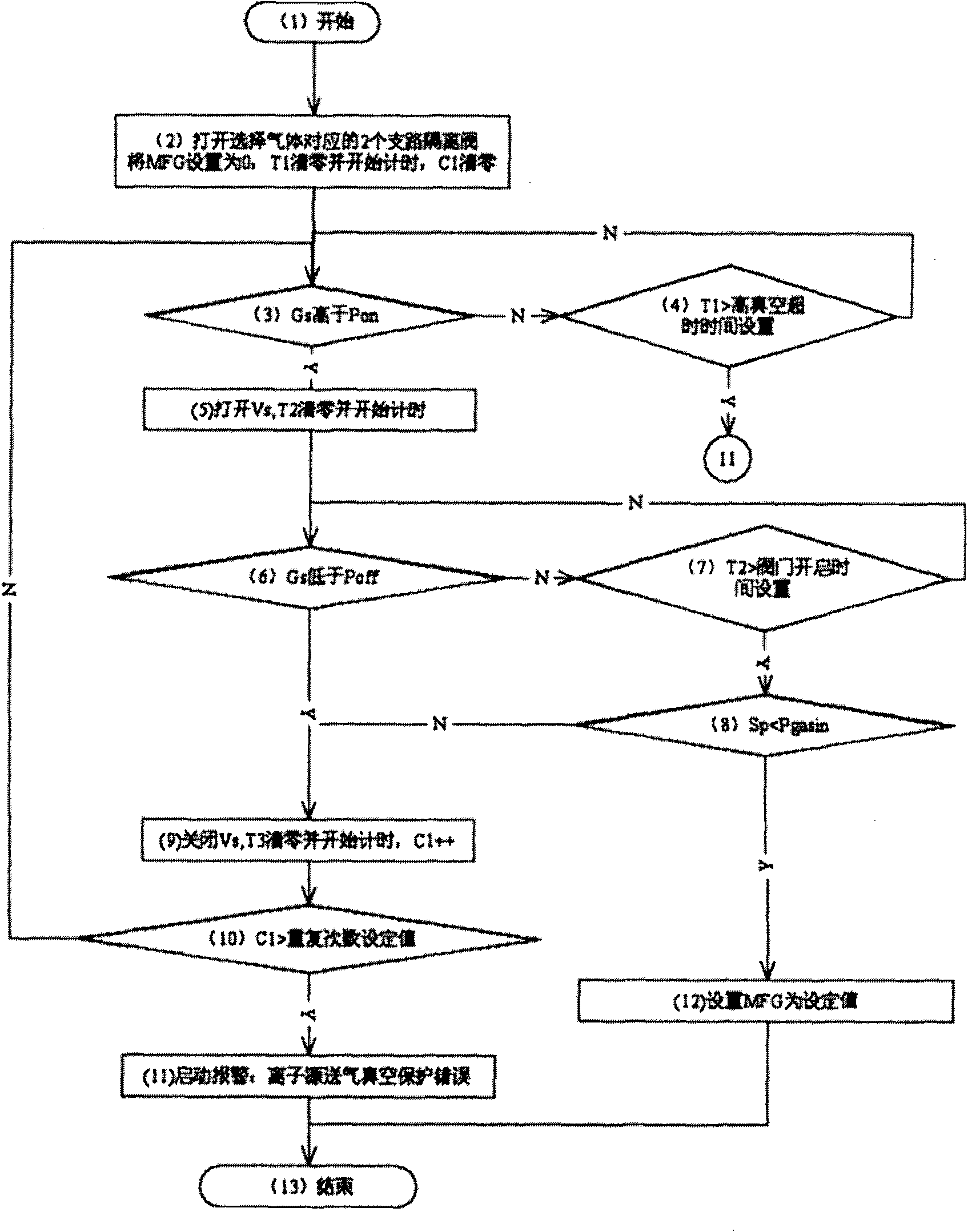

[0018] Attached below figure 2 , to further describe the beam transmission control method of the present invention.

[0019] figure 2 The control process is automatically completed by the computer, and the specific steps are as follows:

[0020] (1) The vacuum shock protection method starts.

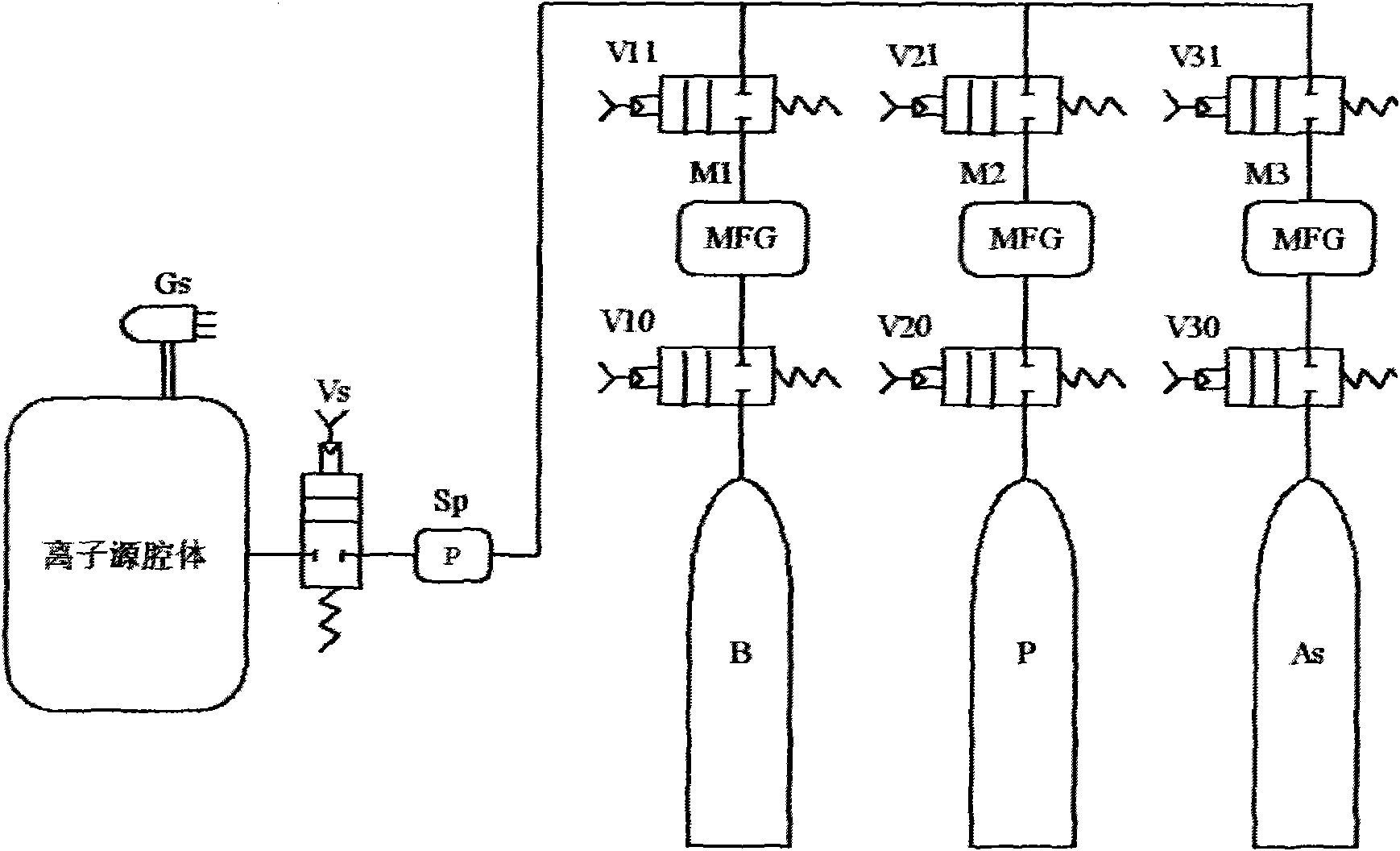

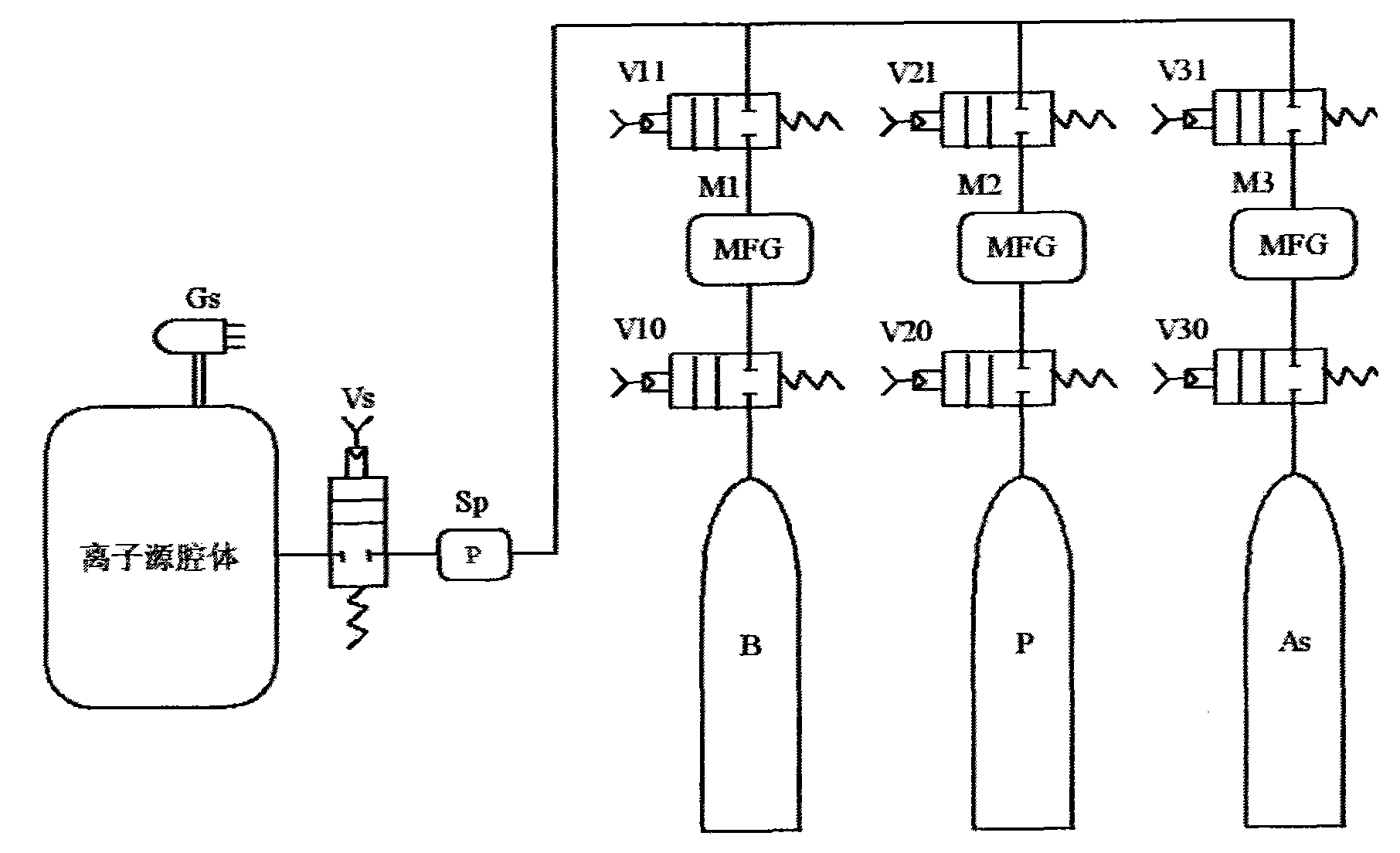

[0021] (2) Select the SDS low-pressure gas cylinder corresponding to the process gas specified in the process menu, set the mass flow meter corresponding to the gas cylinder to zero, and open the branch isolation valve corresponding to the gas cylinder.

[0022] (3) Monitor the ion source vacuum height gauge (hereinafter referred to as Gs), if the ion source vacuum (hereinafter referred to as Ps) is higher than the set value Pon, enter (5) otherwise enter (4).

[0023] (4) If the monitoring time is greater than or equal to the high vacuum timeout time, enter (11) or return to (3).

[0024] (5) Open the ion source gas supply isolation valve (hereinafter referred to as Vs).

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com