LED (Light Emitting Diode) integrated structure with cooler

A technology of cooling device and refrigeration device, which is applied to components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., and can solve problems such as low yield rate of LED chips, poor cooling effect of cooling devices, and short service life. , to save cost and facilitate layout design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

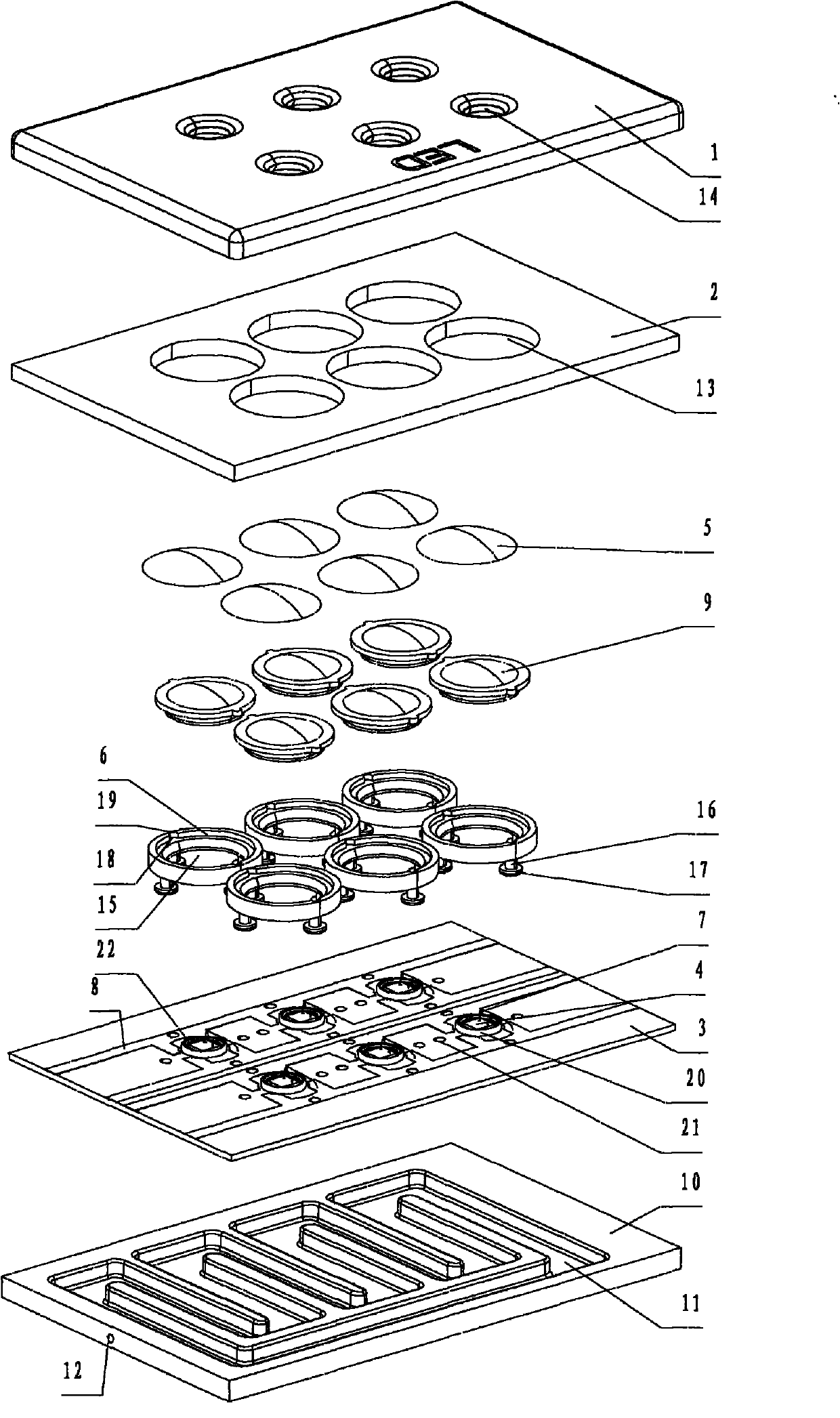

[0079] Such as figure 1 As shown, an LED integrated structure with a cooling device includes a cover plate 1, a reflector plate 2, a heat dissipation substrate 3, an LED chip 4, a lens 5, a lens positioning ring 6, and a gold wire 7 electrically connected to an electrode of the LED chip 4 and the layout circuit conductive layer 8 electrically connected to the gold wire 7 , and the encapsulant 9 used to encapsulate the LED chip 4 and the gold wire 7 . The cooling device includes a flow channel plate 10 arranged on the side of the heat dissipation substrate 3 away from the LED chip 4, a groove 11 is provided on the flow channel plate 10, and a storage cooling is formed between the groove 11 on the flow channel plate 10 and the heat dissipation substrate 3. The water cooling channel and the device for driving the cooling water flow (not shown), the device for driving the cooling water flow is a water pump. A cooling water inlet 12 and a cooling water outlet (not shown) communica...

Embodiment 2

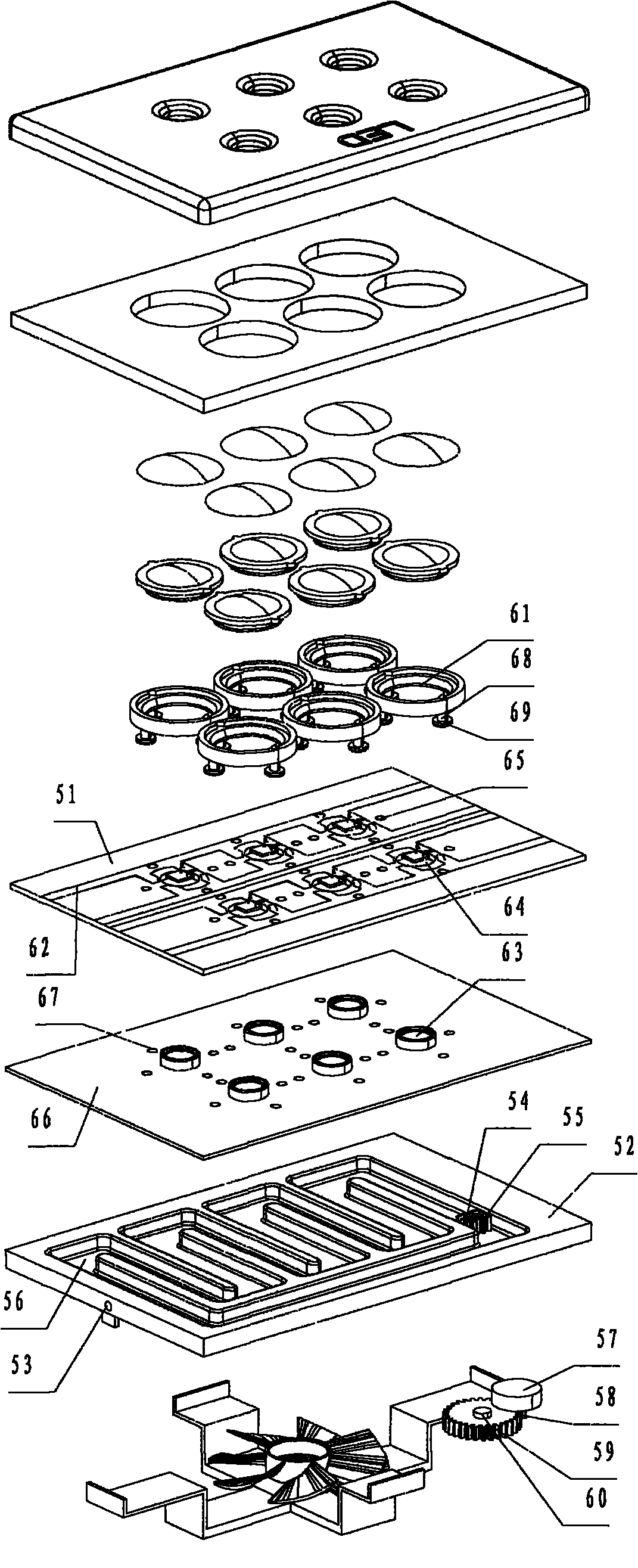

[0084] Such as figure 2As shown, the difference from Embodiment 1 is that an LED integrated structure with a cooling device also includes a PCB board 51 . The flow channel plate 52 is only provided with a cooling medium inlet 53 communicating with the cooling flow channel. The groove 56 on the flow channel plate 52 and the heat dissipation substrate 66 form a closed circulation cooling flow channel, and the cooling medium circulates in the cooling flow channel. The device for driving cooling medium flow includes two first gears 54 and second gears 55 that are engaged with each other installed at the bottom of the groove 56, and are arranged on the side away from the groove 56 to drive the first gear 54 and the second gear 55 to rotate. Motor 57, gear 58 coaxially installed with driving motor 57, gear 59 meshed with gear 58, and magnet 60 fixed with gear 59. The first gear 54 rotates synchronously with the magnet through the magnetic force between the magnet and the magnet. ...

Embodiment 3

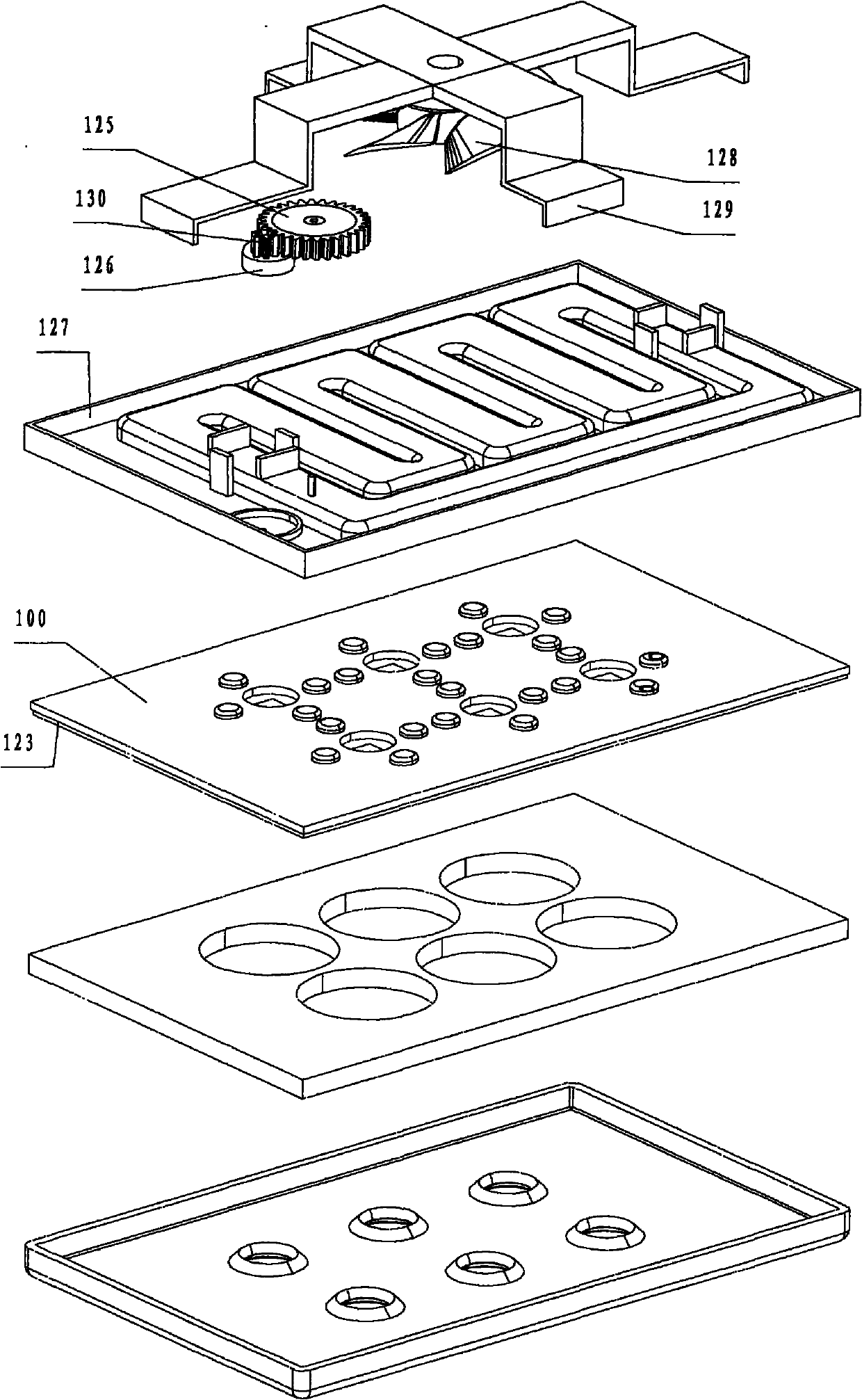

[0088] Such as image 3 As shown, the difference from Embodiment 2 is that the device for driving the cooling medium flow includes two intermeshing first gears (not shown) and second gears (not shown) installed at the bottom of the groove (not shown) 1. The drive motor 126 that is arranged on the side away from the groove to drive the first gear and the second gear to rotate, the gear 130 coaxially installed with the drive motor 126, and the gear 125 meshed with the gear 130 are installed on the channel plate 127 away from the groove The fan 128 on one side of the slot is fixed on the runner plate 127 through a bracket 129 . The first gear is coaxially fixed with the gear 125 and its fixed axis passes through the flow channel plate 127 . The gear shaft of the first gear and the gear shaft of the second gear are liquid-tightly sealed with the bottom of the groove.

[0089] Such as Figure 4 , Figure 5 As shown, the plastic lens positioning ring 101 is connected as a whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com