Line cavity laser with super-narrow line width based on parallel feedback

An ultra-narrow linewidth and laser technology, applied in the field of communication, can solve the problems of high price, increasing the length of the para-erbium fiber, difficulty in ultra-narrow linewidth, etc., and achieve the effects of low cost, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Before describing the embodiment of the ultra-narrow linewidth line cavity laser based on parallel feedback according to the present invention, a brief description of the term "parallel feedback loop" is given first.

[0033] In the present invention, the term "parallel feedback loop" refers to a feedback loop in which the positive feedback loop in the fiber laser is multi-path parallel. Utilizing parallel feedback loops, through the coherent superposition of light between different loops, the spectral characteristics of the final output laser can be improved.

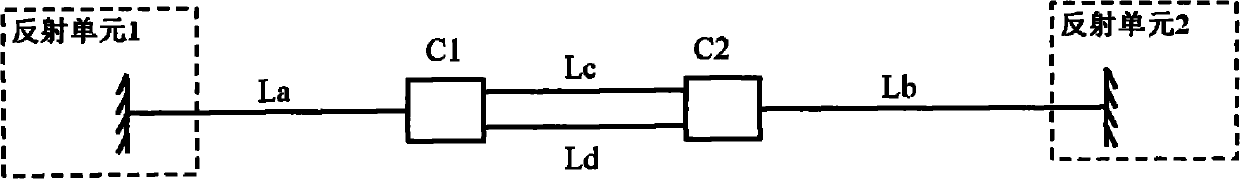

[0034] figure 1 A basic parallel-feedback fiber cavity laser resonator structure is shown. Two couplers C1 and C2 are used in the resonator to build a Mach-Zehnder (MZ) structure. In this resonant cavity structure, there are four different closed resonant circuits. The superscript "+" indicates that the light propagates to the right, and the superscript "-" indicates that the light propagates to the left. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com