Great-power wind-power integration convertor suitable for cage asynchronous generator

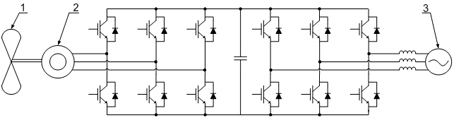

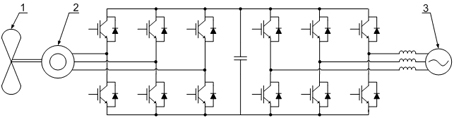

An asynchronous generator, high-power technology, applied in the direction of controlling the generator through the change of the magnetic field, wind power generation, reactive power adjustment/elimination/compensation, etc., can solve the problem of the performance and life of the permanent magnet synchronous generator Differences, magnetic reduction of magnetic steel and other problems, to achieve the effect of enhancing stability and adaptability, high power level, and reducing grid-connected current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

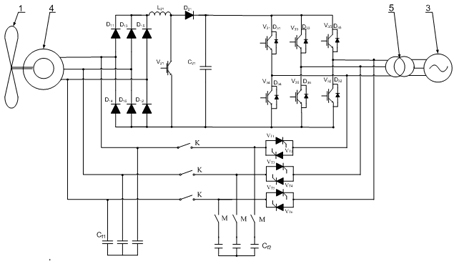

[0029] Refer to attached figure 2 , In the embodiment, the present invention is located between the megawatt wind turbine 1 , the cage-type asynchronous generator 4 , the grid-connected transformer 5 , and the grid 3 . The invention includes: rectifier unit, step-up chopper unit, inverter unit, motor soft start excitation unit C f1 (also has grid-side filtering function), grid-side three-phase reactive power compensation switching capacitor unit C f2 . Wind turbine 1 and cage-type asynchronous generator 4 are connected to the rectifier unit, the rectifier unit is connected to the boost chopper unit, the boost chopper unit is connected to the inverter unit, and the inverter unit is connected to the motor soft start excitation unit and grid-side three-phase reactive power compensation unit, where the motor soft start excitation unit C f1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com