Filter element for filtering high-temperature dust and purifying gas as well as preparation method and application thereof

A technology for dust filtration and gas purification, which is applied in chemical instruments and methods, separation methods, and dispersed particle filtration, etc. It can solve problems such as poor thermal shock resistance, difficult sealing and packaging of ceramic membrane tubes, and fractures, so as to reduce the degree of poisoning , Overcoming the difficulty of assembly and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

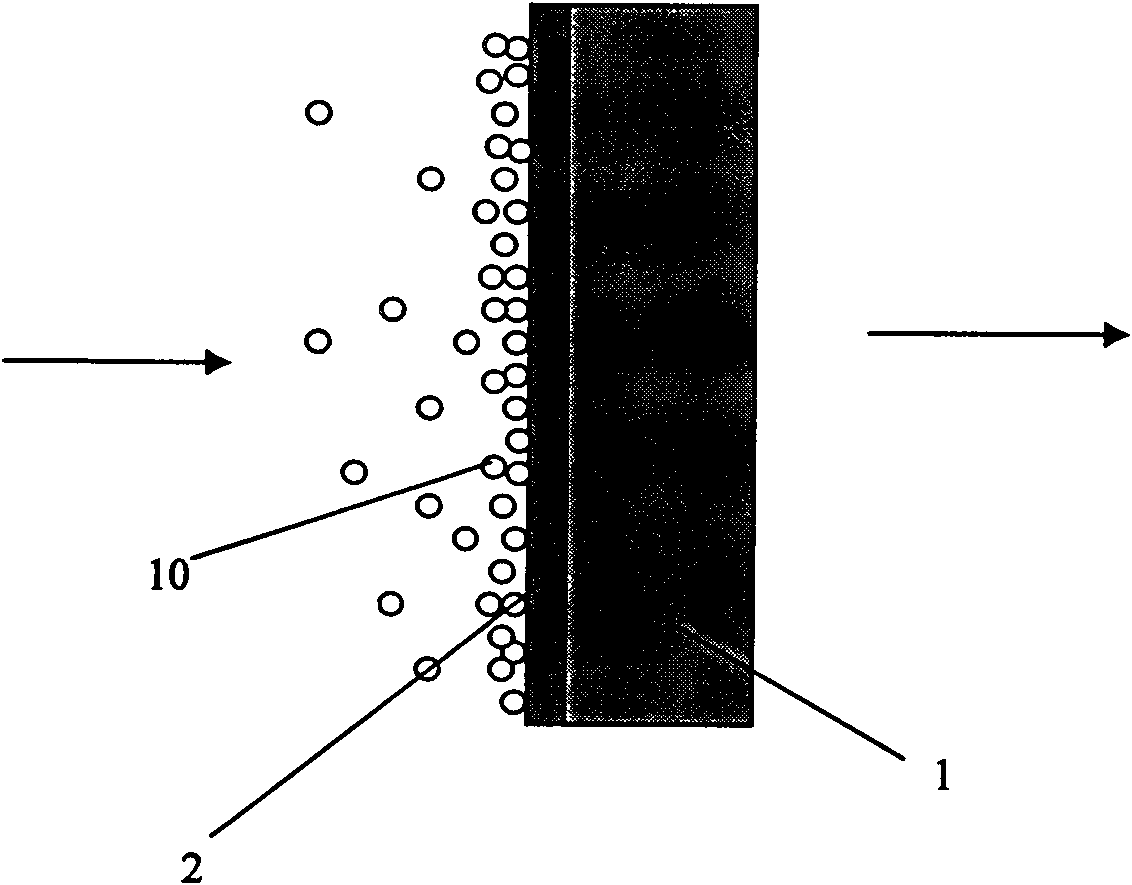

[0034] A method for preparing the above-mentioned filter element for high-temperature dust filtration and gas purification, comprising the following steps:

[0035] (1) Production of the support body 1: select the material used to make the support body 1, weigh the required support body raw material and its additives; when the selected support body raw material is a metal powder sintered material, adopt cold isostatic pressing -The support body 1 is formed by vacuum sintering, wherein the high-temperature sintering is carried out in a vacuum sintering furnace, the sintering temperature is 850-1450°C, and the sintering holding time is 1-5 hours; when the selected support body 1 is made of metal fiber sintered felt , the support body 1 is formed by a dry non-woven felting method, wherein the high-temperature sintering is carried out in a vacuum sintering furnace, the sintering temperature is 950-1350° C., and the holding time is 1-5 hours;

[0036] (2) The making of filter membr...

Embodiment 1

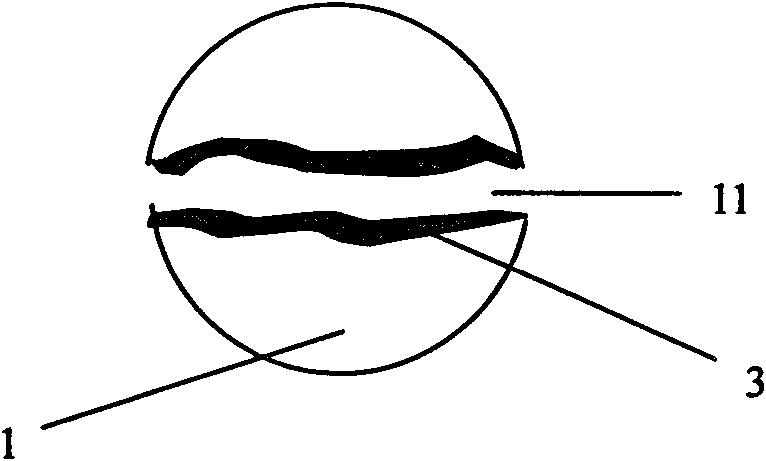

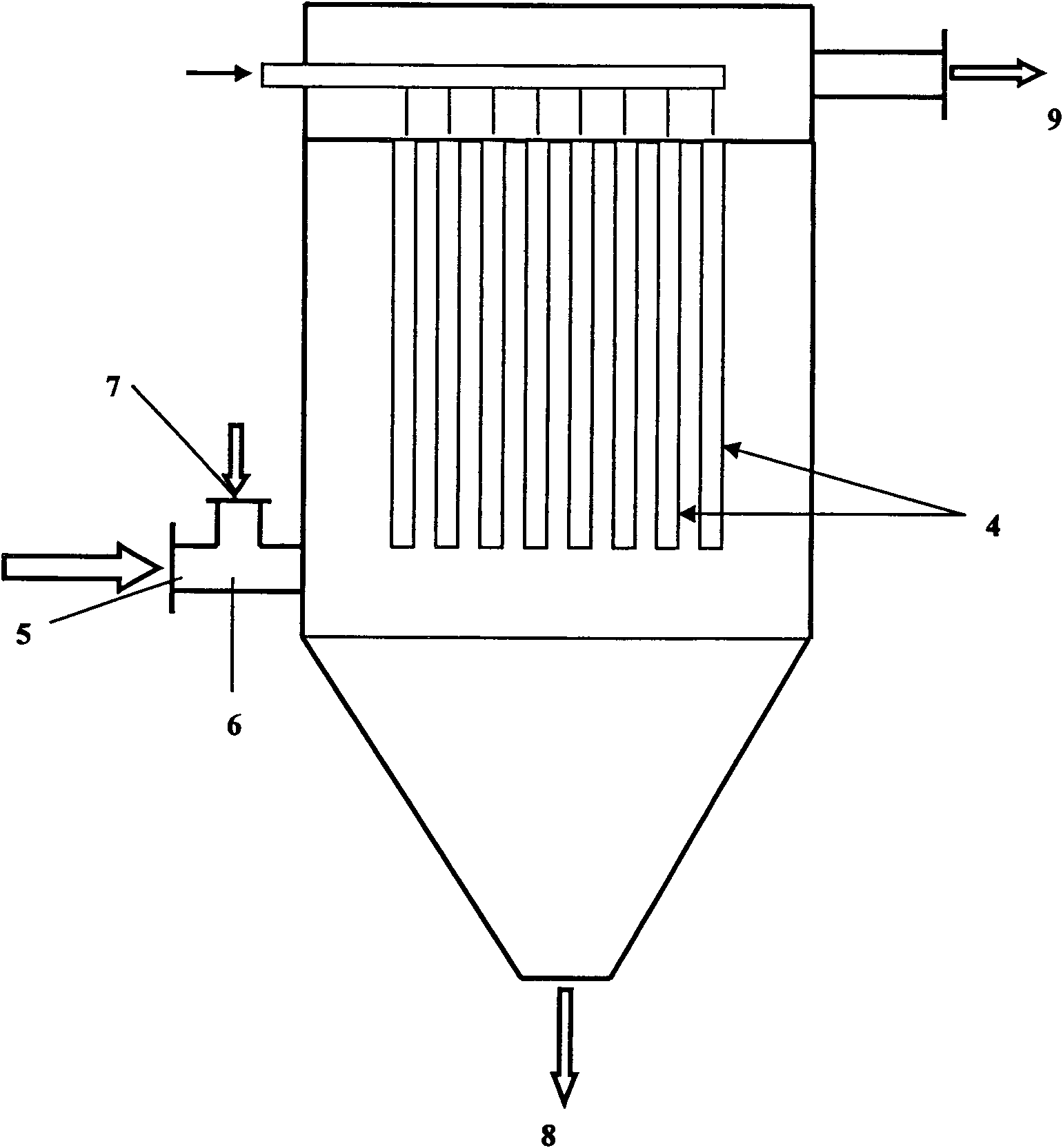

[0043] In this embodiment, the support body 1 is a 316L stainless steel powder sintered filter element with a diameter of 50 mm, a length of 300 mm, a wall thickness of 3 mm, and a filtration precision of 25 μm. The support body 1 is prepared by cold isostatic pressing method-high temperature vacuum sintering, wherein the pressure of cold isostatic pressing is 150Mpa, the sintering temperature is 1230°C, and the holding time is 2 hours; then, the method of vacuum spraying is used on the support The surface of the body is sprayed with a layer of filter membrane 2 with a thickness of 0.3 mm and a filtration accuracy of 8 μm; the dried workpiece is vacuum sintered at a temperature of 1100 ° C for 1.5 hours; Internally loaded denitration catalyst (V 2 o 5 -WO 3 / TiO 2 )3. The filter elements thus prepared can be further processed into components of tubular filter elements, and then assembled into filter containers, which can be used for filtering high-temperature dust and puri...

Embodiment 2

[0045] In this embodiment, the support body 1 is a Fe with a diameter of 80 mm, a length of 500 mm, a wall thickness of 3 mm, and a filtration accuracy of 30 μm. 3 Al powder sintered filter element. Support body 1 is prepared by cold isostatic pressing method-high temperature vacuum sintering, wherein the pressure of cold isostatic pressing is 200Mpa, the sintering temperature is 1250°C, and the holding time is 2 hours; The surface of the body 1 is sprayed with a layer of filter membrane 2 with a thickness of 0.3 mm and a filtration accuracy of 10 μm; the dried workpiece is vacuum sintered at a temperature of 1180 ° C for 1.5 hours; The denitration catalyst loaded in the pores (V 2 o 5 -WO 3 / TiO 2 )3. The filter elements thus prepared can be further processed into components of tubular filter elements, and then assembled into filter containers, which can be used for filtering high-temperature dust and purifying gases in thermal power generation, waste incineration, iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com