Molybdenum target welding method

A welding method and target technology, which are used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large deformation, low welding strength, unable to meet the requirements of sputtering process, etc., to suppress deformation and improve welding strength. , reduce the effect of relative deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The inventors of the present invention found that after welding the existing molybdenum or molybdenum alloy target components and the back plate, especially the copper back plate, the welding quality cannot meet the high strength requirement of the sputtering process.

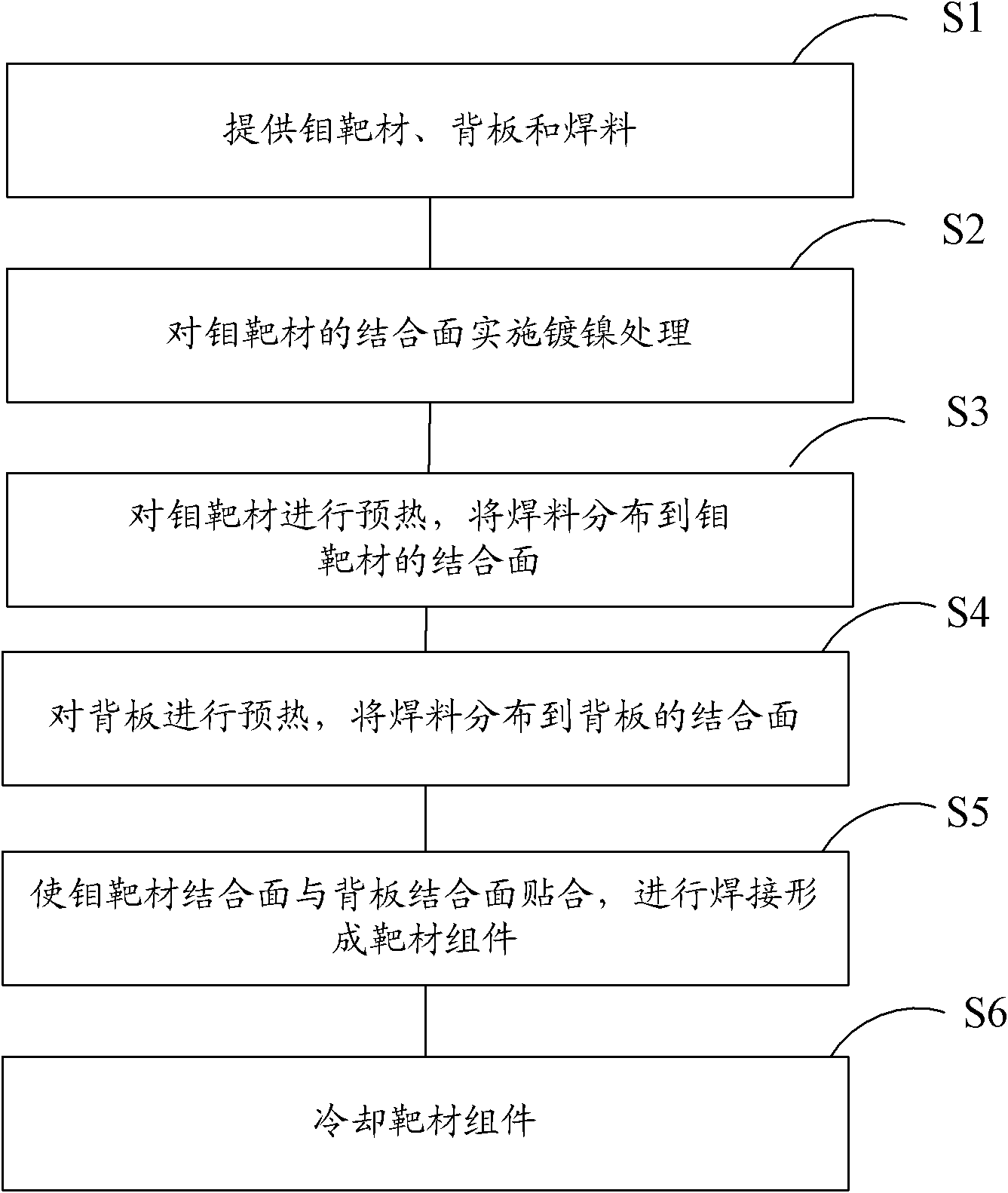

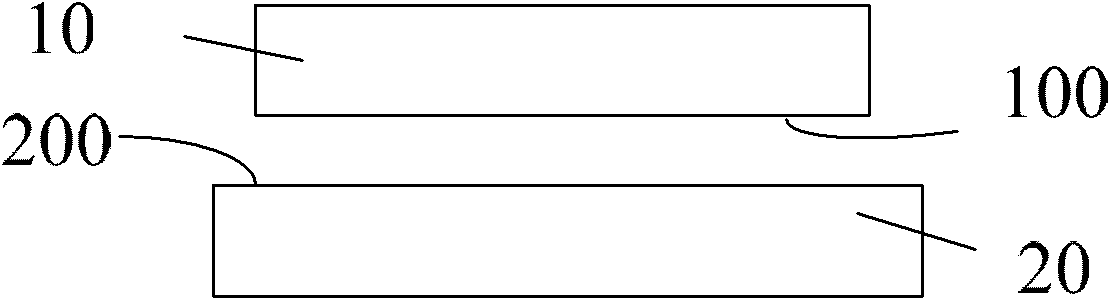

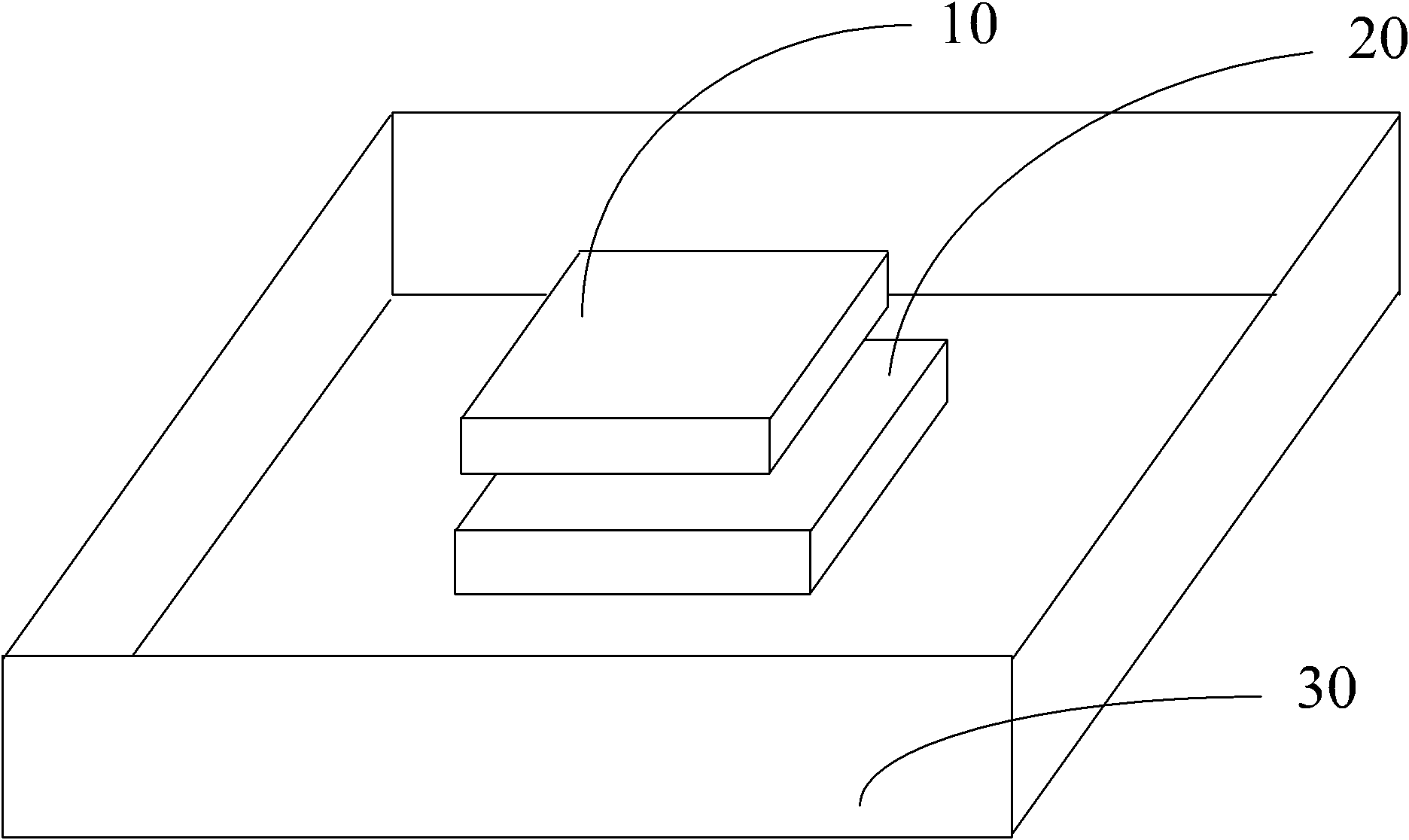

[0028] The invention provides a welding method for a target assembly, which includes: providing a molybdenum or molybdenum alloy target, a back plate and solder; performing nickel plating on the joint surface of the molybdenum or molybdenum alloy target; coating the molybdenum or molybdenum alloy Preheating the target, so that the solder is distributed on the joint surface of the molybdenum or molybdenum alloy target; preheating the back plate, so that the solder is distributed on the joint surface of the back plate; making the molybdenum or molybdenum alloy The bonding surface of the target is attached to the bonding surface of the back plate and welded to form a target assembly; the target assembly is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com