Mounting structure for power battery pack of electric automobile

A power battery pack and electric vehicle technology, applied in the direction of electric power unit, power unit, superstructure, etc., can solve the problems of battery failure, unreasonable, high energy of lithium battery, etc., achieve collision safety guarantee and occupy a small space in the car body , the effect of simple internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

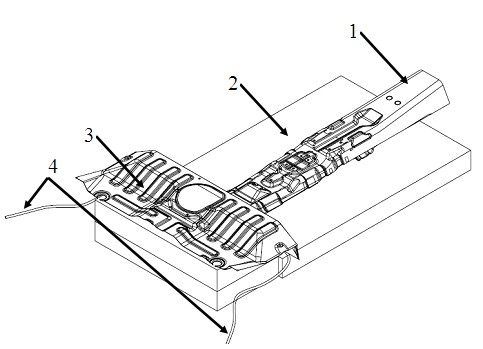

[0023] see figure 1 , figure 2 , the battery pack 2 is rectangular as a whole, and is in the shape of a ladder with one end high and the other end low, its high end is arranged in the height space 10 miles under the rear seat floor 3, and its short end is arranged under the front cab seat floor . Because the battery pack is arranged under the chassis of the car, the central pipeline 1 of the original car and the hand brake mechanism 4 of the traditional car are retained, and the hand brake wiring harness 4 is drawn from the two ends of the rear row base 3 transversely.

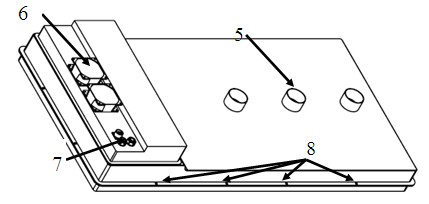

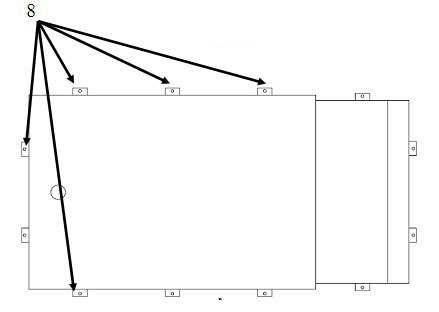

[0024] The central duct 1 of the original car is used to set up the battery heat dissipation air duct, and the three air inlets 5 on the battery pack are arranged longitudinally and correspondingly below the central duct 1, and the two air outlets 6 are arranged horizontally and correspondingly at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com