Method for treating mercury-containing wastewater with three-section continuous process

A waste water and process technology, applied in chemical instruments and methods, adsorption water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of poor treatment effect of mercury-containing waste water and environmental pollution, and achieve small investment and reduced production Simple and reasonable cost and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

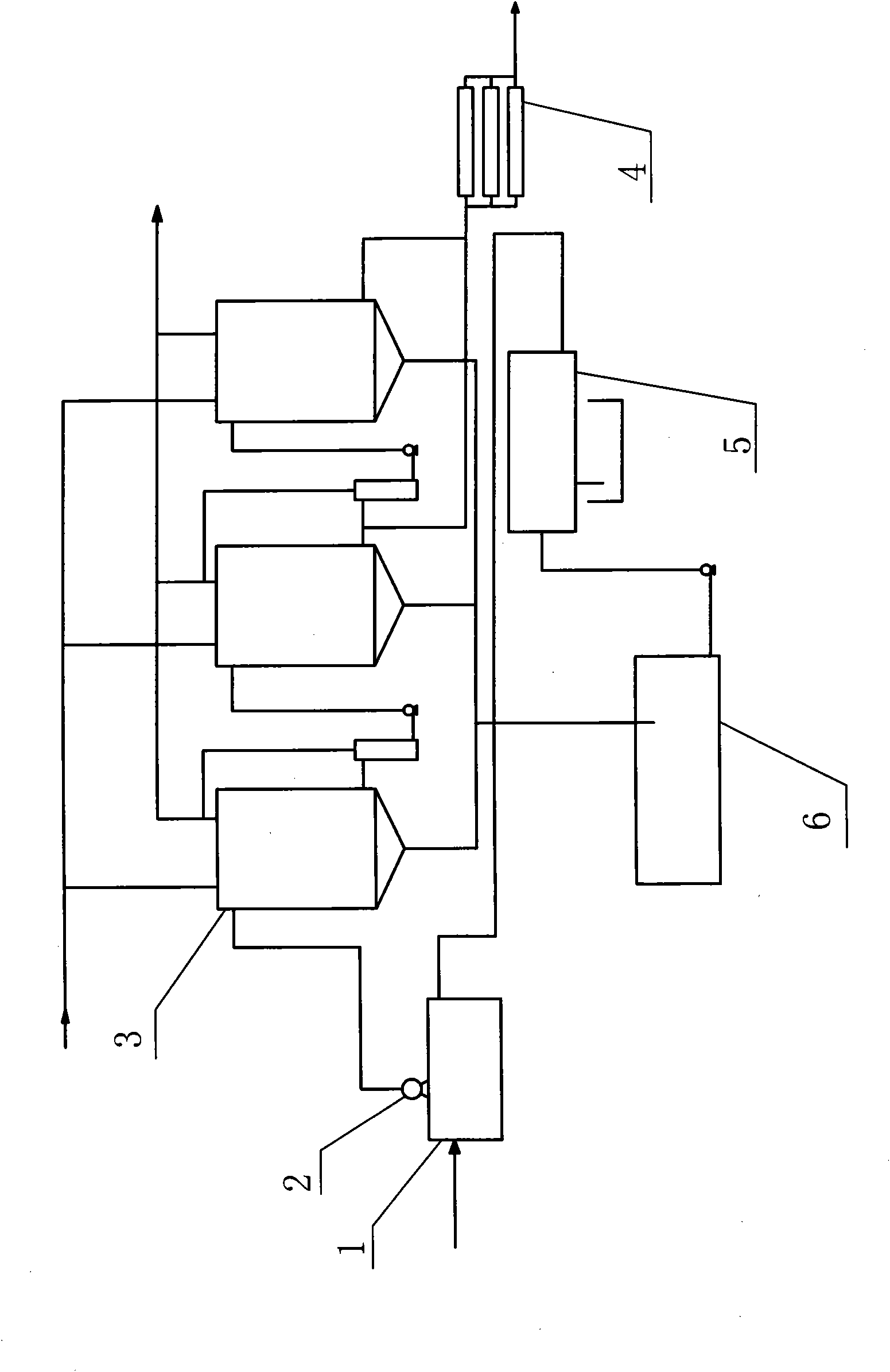

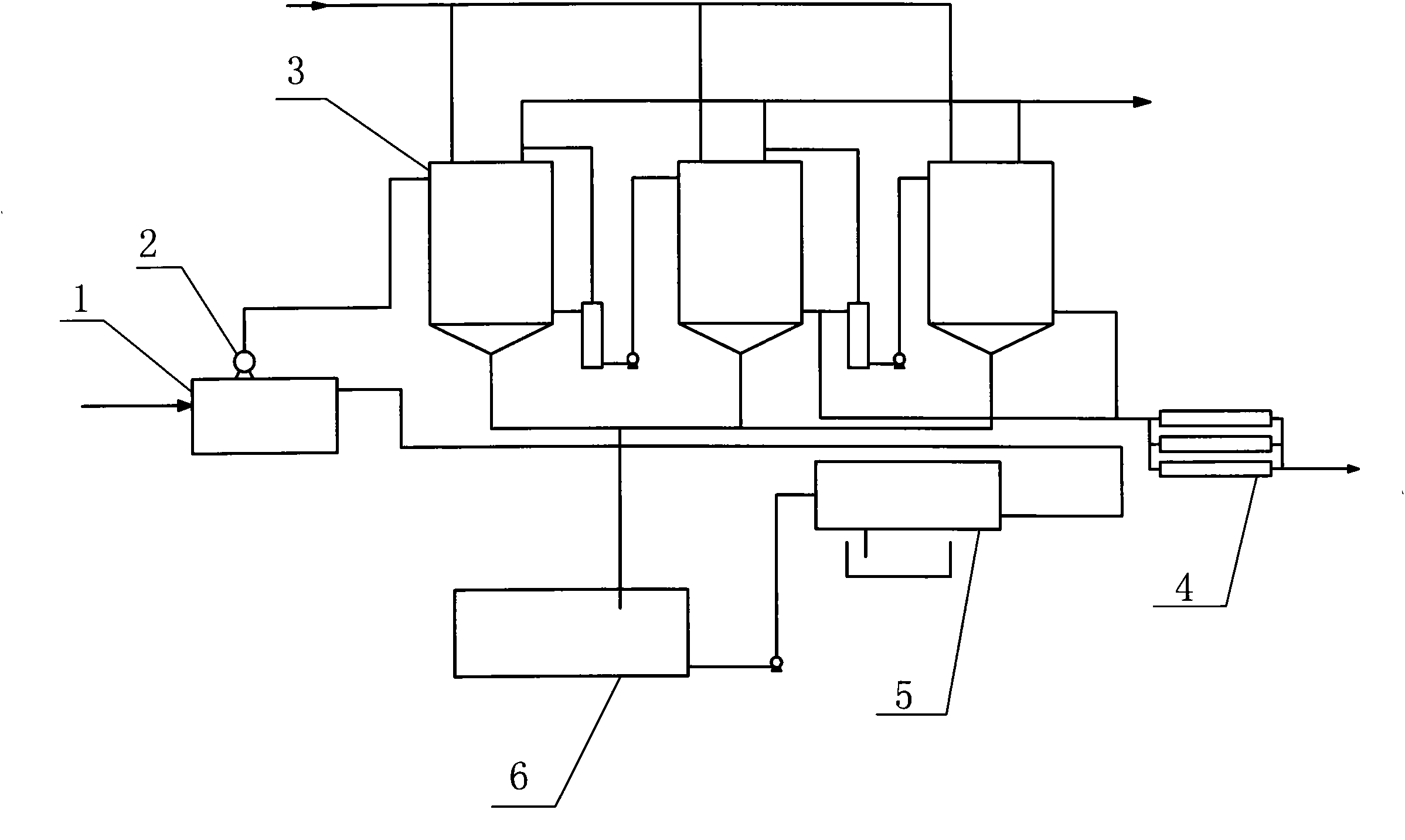

[0014] Refer to attached figure 1 Among them, the present embodiment comprises the following steps: the mercury-containing waste water is adjusted to 9-11 through the pH adjustment pool 1, and pumped into the reaction tank 3 by the pump 2, and Hg:Na is added in the reaction tank at the same time. 2 The mass concentration ratio of S=1:5-1:20, the sedimentation agent Na with a mass concentration of 0.5-0.6 2 The S solution is fully reacted, and then an inorganic flocculant with a mass concentration of 0.01-0.03 is added, and the generated HgS flocculent precipitates naturally, and the supernatant is filtered by a multi-section filter 4 to reach the discharge standard, and the precipitated HgS precipitates After passing through the solid-liquid separation device 5, the sludge goes to the sludge concentration tank 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com