Fluid resistance reduction composition

A composition and fluid technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of low drag reduction efficiency, high price, high shear stress resistance, etc. less harmful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

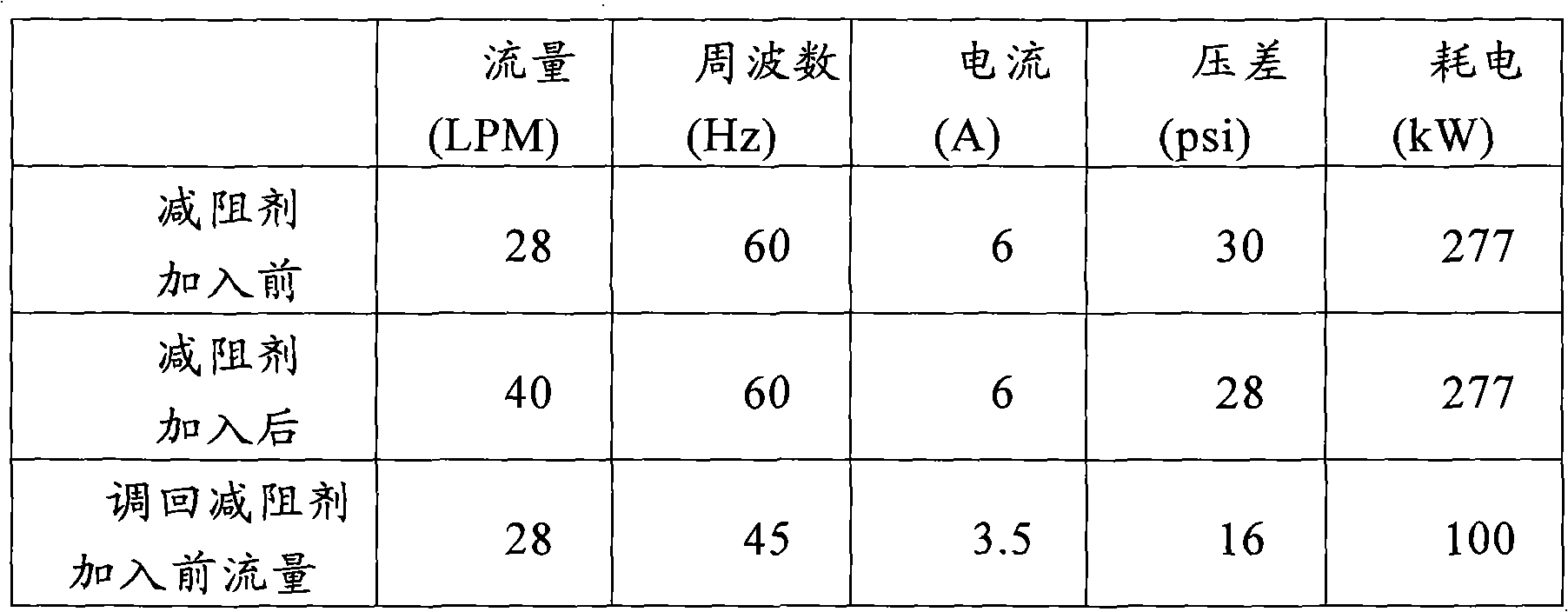

[0042] Embodiment: drag reducing agent drag reduction experiment

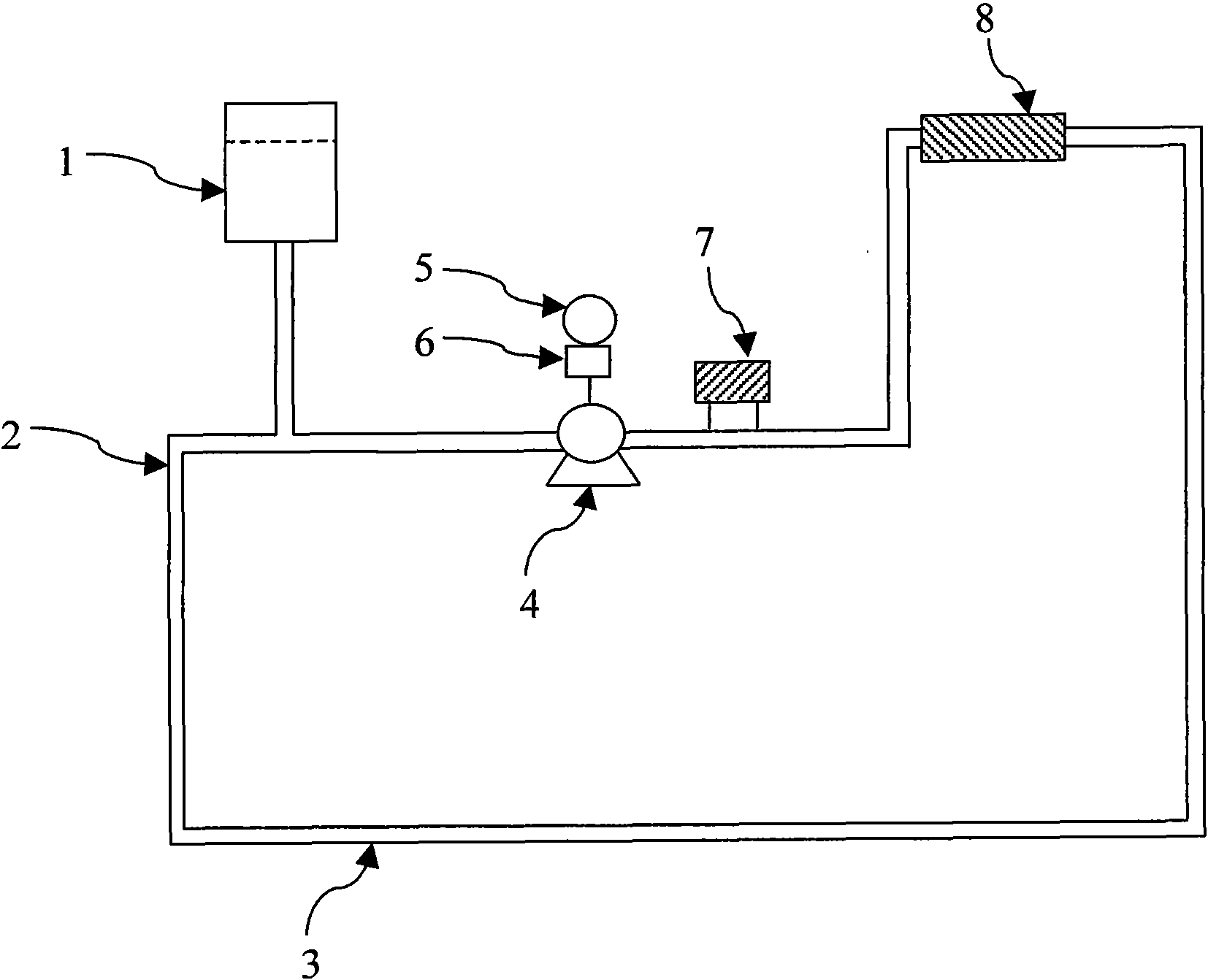

[0043] The present invention utilizes a self-made fluid flow circuit system as an evaluation of the fluid drag reducing composition of the present invention for reducing fluid resistance and reducing pump power consumption. For a diagrammatic description of the system, please refer to figure 1 .

[0044] The composition weight percent of the drag reducing agent that embodiment uses is: water 41.5%, 2-hydroxybenzoic acid sodium 24%, sodium benzoate 6%, sodium nitrite 14%, cetyl trimethyl ammonium chloride 10%, oil 2% Trimethylamide, 2% Octadecyltrimethylammonium Chloride and 0.5% Sodium Hydroxide. The drag reducer is added to the water-containing expansion tank 1 in an amount of 0.1% to 0.5% relative to the water, and the added amount can be adjusted according to parameters such as water quality, water temperature, pipe diameter, pipe length, and lift. The system includes a 6.5m 3 / 4 hour hard pipe 2 and a 20m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com