System and method for temperature reduction and pressure stabilization of liquefied natural gas storage tank

A liquefied natural gas and liquid nitrogen storage tank technology, which is applied in the field of liquefied natural gas storage, can solve the problems of unsuitable liquefied natural gas storage tanks, not widely used, contrary to liquefied natural gas, etc., and achieves a simple structure, easy-to-understand structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

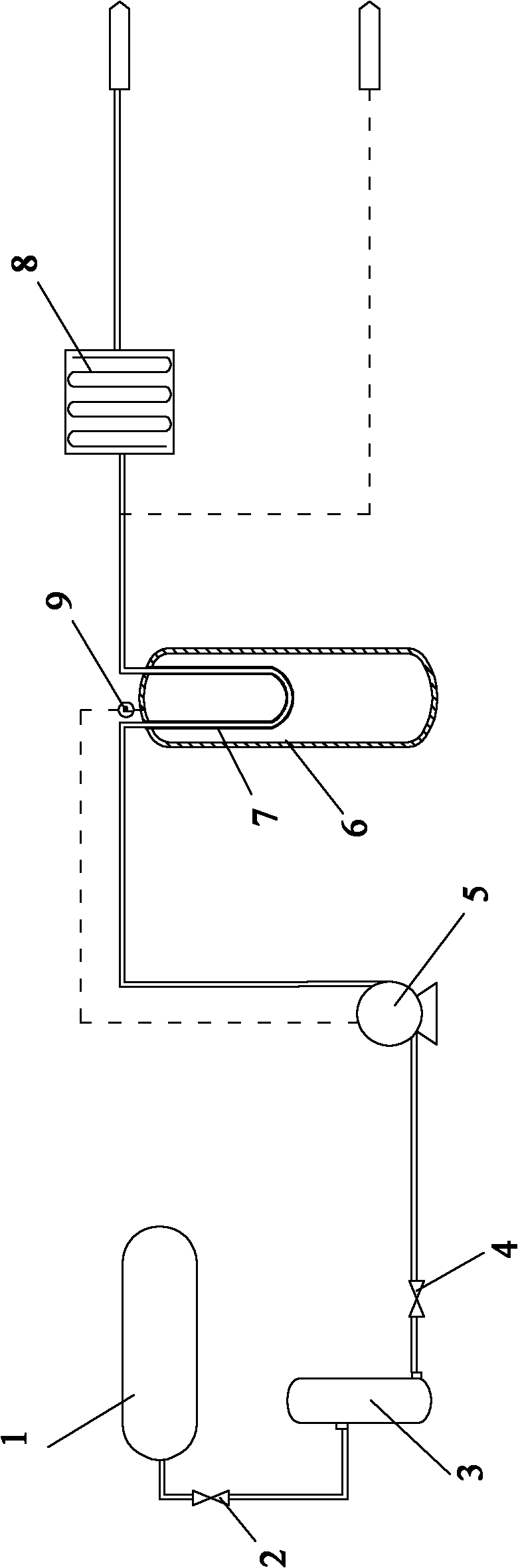

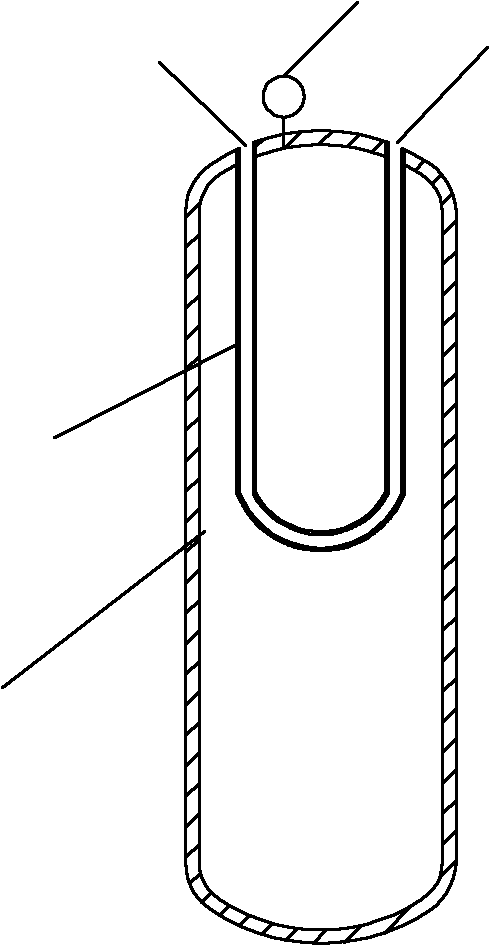

[0034] Such as figure 1 As shown, the cooling and stabilizing system for the LNG storage tank includes a liquid nitrogen delivery device, an LNG storage tank 6 and an exhaust pipe, such as figure 2 As shown, the liquefied natural gas storage tank 6 is provided with a heat exchange tube 7, the inlet 10 of the heat exchange tube 7 is connected to the liquid nitrogen delivery device through a pipeline, and the outlet 11 is connected to an exhaust pipeline through a pipeline; The tank 6 is provided with a pressure sensor 9 connected to a liquid nitrogen conveying device, and the exhaust pipe is provided with a vaporizer; the liquid nitrogen conveying device is externally connected to a liquid nitrogen source 1.

[0035] The vaporizer is an air temperature vaporizer 8.

[0036] The liquid nitrogen delivery device includes a liquid nitrogen storage tank 3 and a pump 5. The liquid nitrogen storage tank 3 is externally connected to a liquid nitrogen source 1. One end of the pump 5 is conne...

Embodiment 2

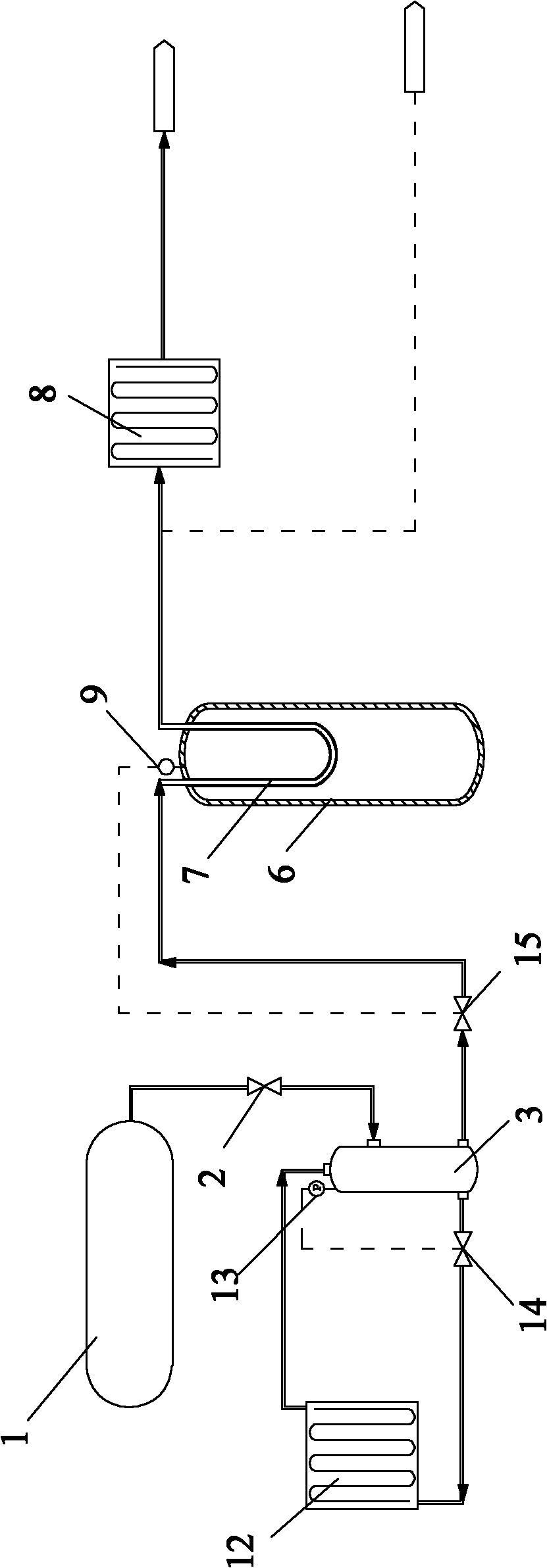

[0046] The other features of this embodiment are the same as those of the first embodiment except for the following features: image 3 As shown, the liquid nitrogen delivery device includes a liquid nitrogen storage tank 3 and a self-pressurizing vaporizer 12. The liquid nitrogen storage tank 3 is respectively connected to the liquid nitrogen source 1 and the inlet of the heat exchange tube 7 through pipelines, and The nitrogen storage tank 3 is provided with a vaporization inlet and a vaporization outlet. The self-pressurized vaporizer 12 is connected to the vaporization inlet and the vaporization outlet of the liquid nitrogen storage tank 3 through pipes; on the pipe connecting the self-pressurized vaporizer 12 and the vaporization inlet A vaporization valve 14 is provided, a pressure sensor 13 is provided on the liquid nitrogen storage tank 3, and the vaporization valve 14 is connected to the pressure sensor 13;

[0047] The pipeline connecting the liquid nitrogen source 1 and...

Embodiment 3

[0053] The other features of this embodiment are the same as those of the first embodiment except for the following features: the length of the heat exchange tube in the height direction of the LNG storage tank is 5m. The heat exchange tube is a serpentine coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com