Passive optical fiber temperature semiconductor sensor

An optical fiber temperature, semiconductor technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of partial discharge, high cost, complex structure, etc., to achieve convenient connection, resistance to external electromagnetic interference, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

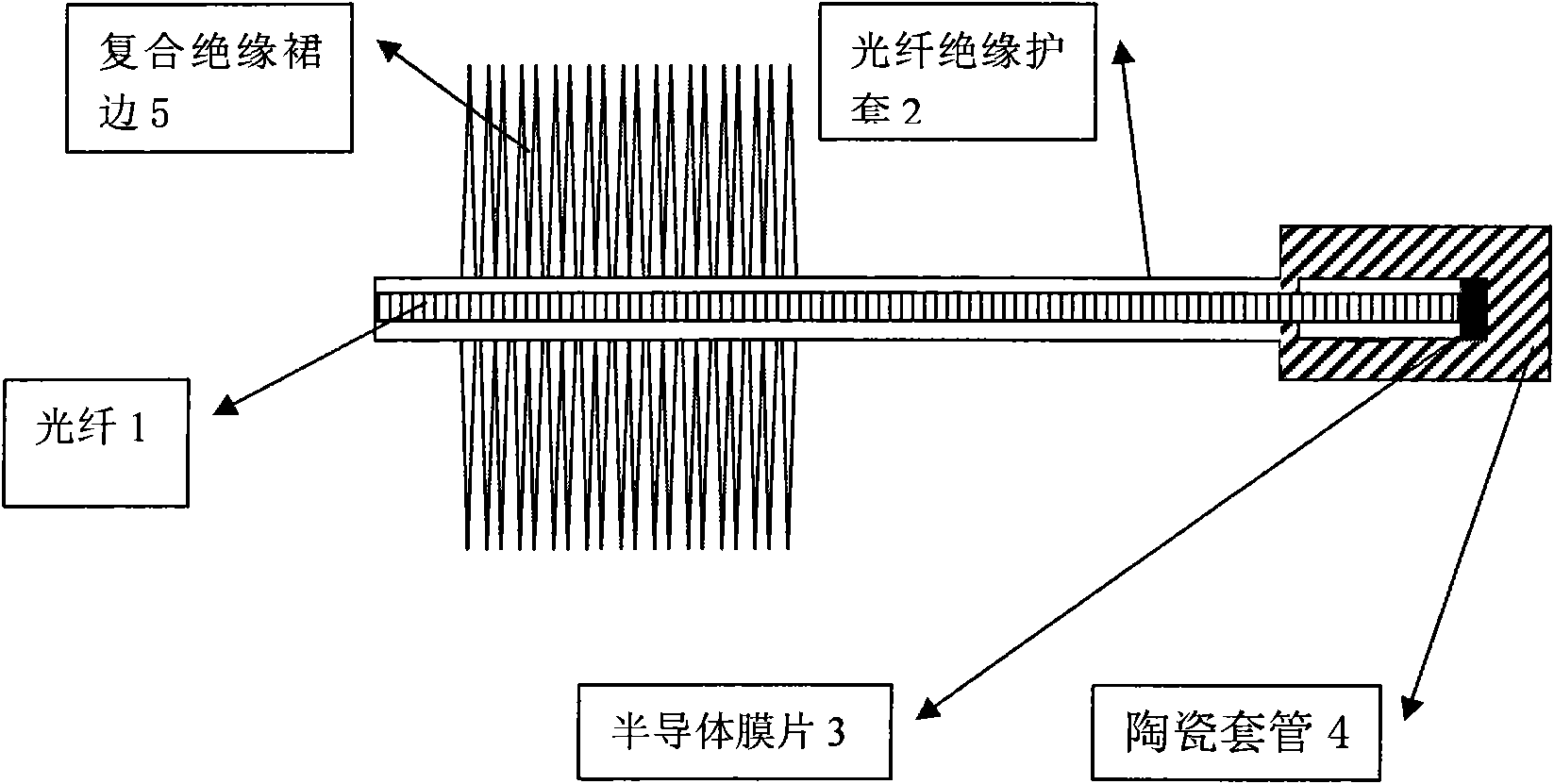

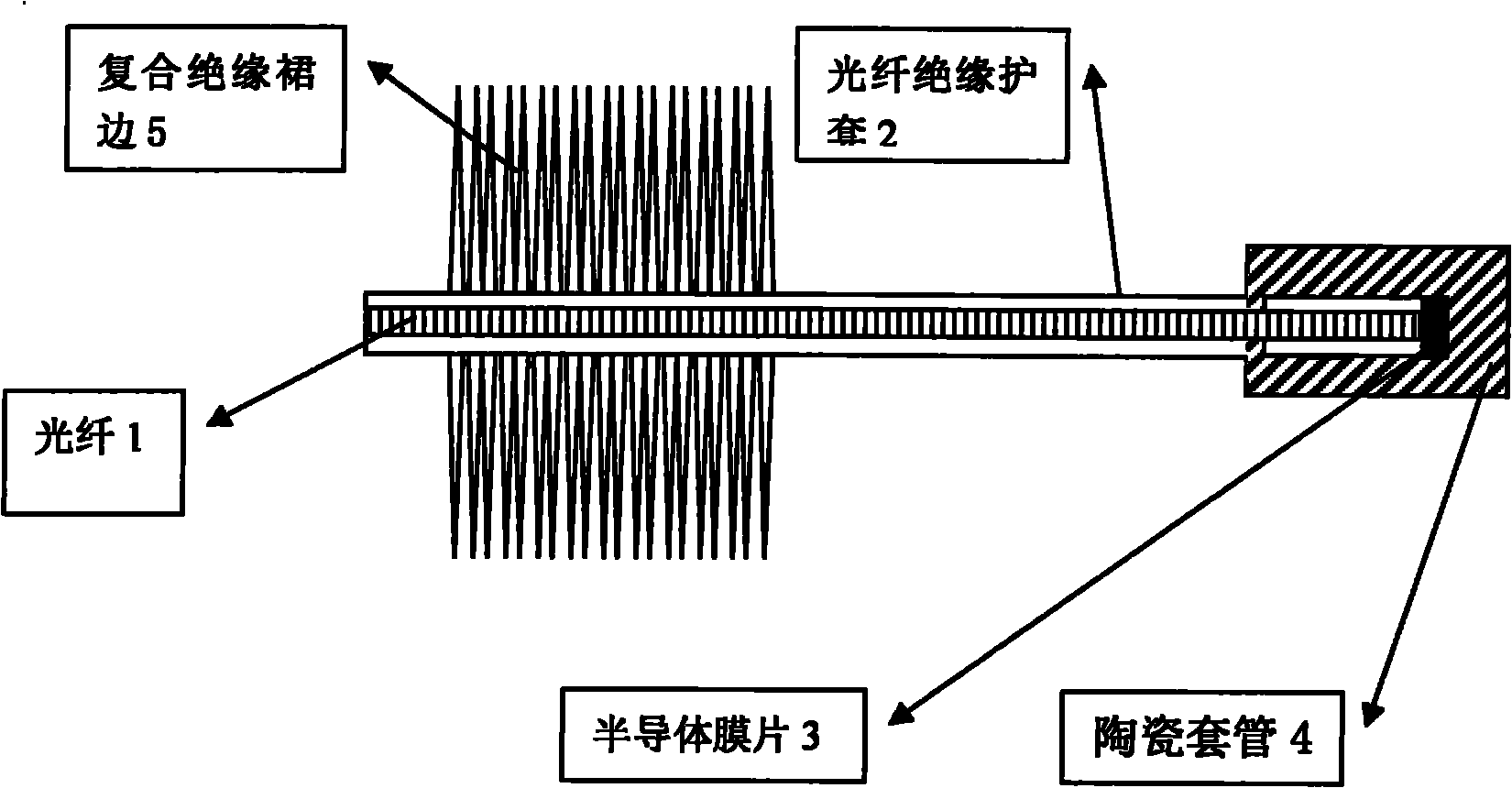

[0013] Embodiment 1: as figure 1 , including an optical fiber 1, an optical fiber insulating sheath 2, a composite insulating skirt 5, a semiconductor diaphragm 3 and a ceramic sleeve 4. Its structural feature is that an optical fiber insulating sheath 2 is tightly wrapped outside the optical fiber 1, and there are several composite insulating skirts 5 made of silicon rubber on the outer insulation of the optical fiber insulating sheath 2; the end surface of the optical fiber 1 is coated with a semiconductor diaphragm 3, Insert one end of the semiconductor diaphragm 3 into a ceramic bushing 4, and seal the contact between the plug and the ceramic bushing 4 with epoxy glue. The ceramic bushing can not only protect the optical fiber pin sensor head, but also shield external interference.

[0014] The laser emits laser light and hits the semiconductor diaphragm 3 through the optical fiber 1. According to the refractive index-temperature physical characteristics of the semiconduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com