Microbial biomass, feed product/ingredient and processes for production thereof

A technology of microbial biomass and microorganisms, applied in the direction of biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problem of expensive sources of microalgae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 (cultivation of microbial biomass)

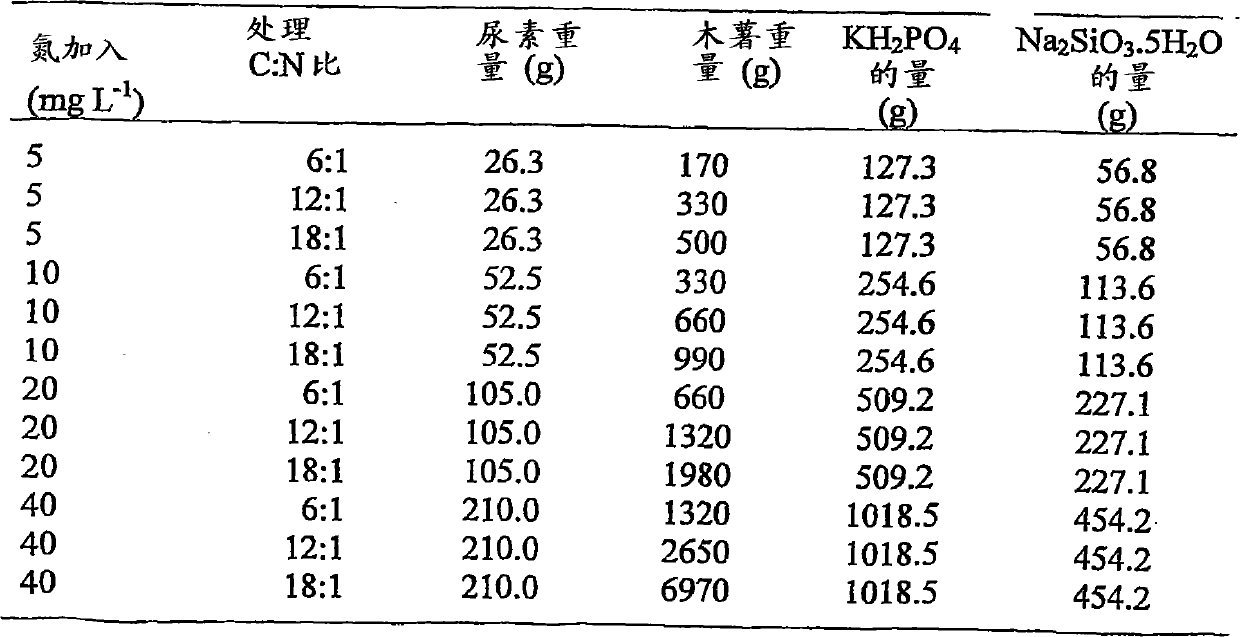

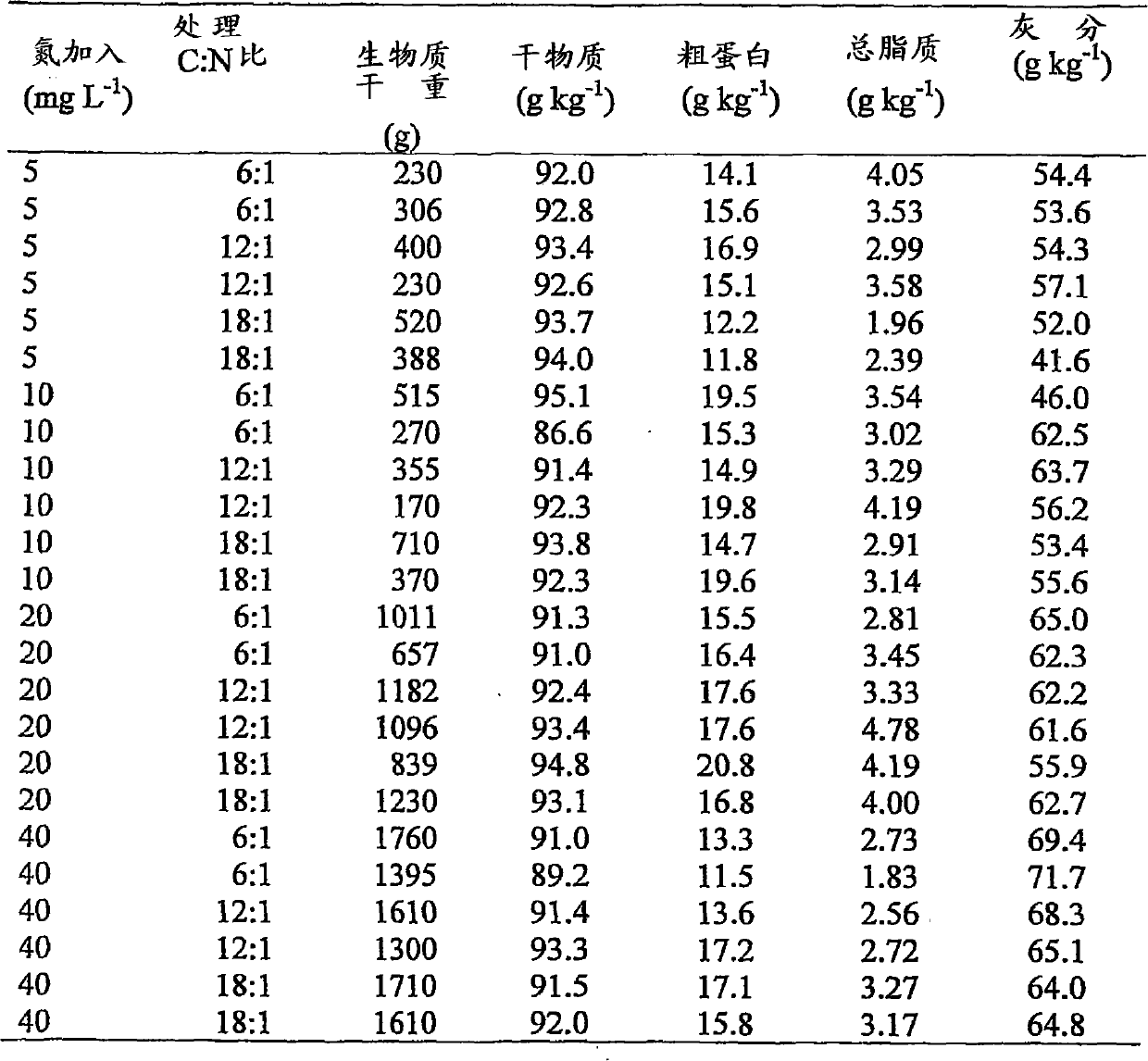

[0060] To obtain an indication of optimal levels of nitrogen and readily available carbon sources in microbial biomass production, a first experiment was performed. The experiment consisted of 12 treatments, where each group consisted of two identical tanks. The treatments included 4 nitrogen (N) concentrations in 12 tanks (Table 1). The nitrogen source is urea fertilizer. Organic carbon in the form of tapioca starch was added to two identical tanks with each concentration of N for C:N ratios of 6:1, 12:1 and 18:1 (Table 1). The tank used to grow the microbial biomass was a circular fiberglass tank (2450L working volume) located in a horticultural tunnel house with minimal attenuation of natural light and maintained water temperature at 25-33°C.

[0061] The tanks were filled with filtered seawater (20 μm) and the experiment was started 5 weeks later. Additional microorganisms were added by adding 20 L of unfiltered se...

Embodiment 2

[0068] Example 2 (Cultivation of microbial biomass using lupine pods)

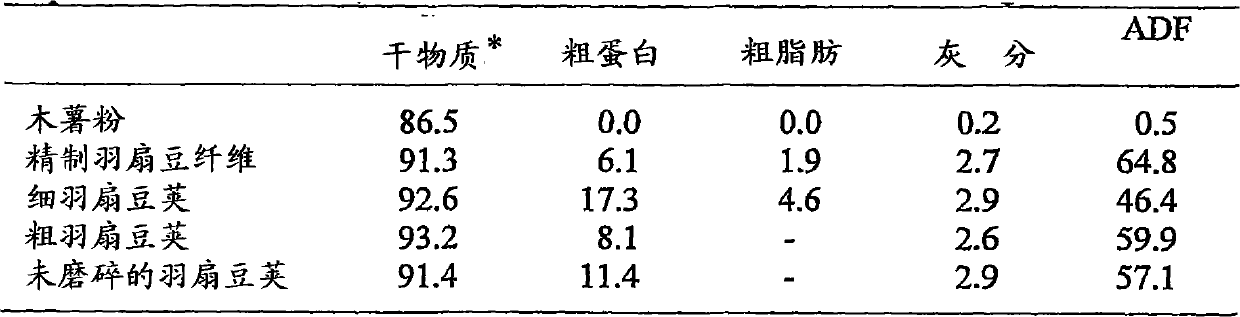

[0069] This example was performed to evaluate the use of lupine pods as a low-cost carbon source for microbial biomass cultivation and to compare the yields obtained using lupine pods and tapioca starch. The lupine pods are a by-product of processing lupine seeds to obtain lupine kernels. Samples of lupine pods were passed through a hammer mill to reduce their size and thus provide a greater surface area to volume ratio. This is expected to increase the rate of biotransformation of lupine pod material by the microbial community in the culture tank. The ground material appeared to contain two broad particle size fractions which were sieved with a 710 μm sieve to separate them. The two fractions provide two carbon sources. Analysis of the fractions revealed minor differences in similar composition (Table 3). Refined lupine fiber is included as an additional treatment, a product that is commercially pre...

Embodiment 3

[0083] The goal of this study was to investigate differences in the nutritional value of various microbial biomass cultures when added to feeds for black tiger shrimp - Penaeus monodon . The microbial biomass was produced as outlined in Examples 1 and 2 at Cleveland using CSIRO equipment in a 2500L tank. This study was conducted in the Clearwater Aquarium system.

[0084] The experiments involved using a basal diet and both containing 100 g kg -1 A 35-day feeding trial with a series of 15 diets of dry microbial biomass from different culture batches. The formulations of the basal diet and the three test diets are shown in Table 1 to illustrate the manner in which the diets were formulated.

[0085] During the preparation process, crude protein content and fat content (75g kg -1 DM) were maintained at the same level in all diets (420g kg -1 and 75g kg -1 DM). The same level (100 g kg -1 ), and adjust the amount of casein, vegetable oil mixture and wheat starch to balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com