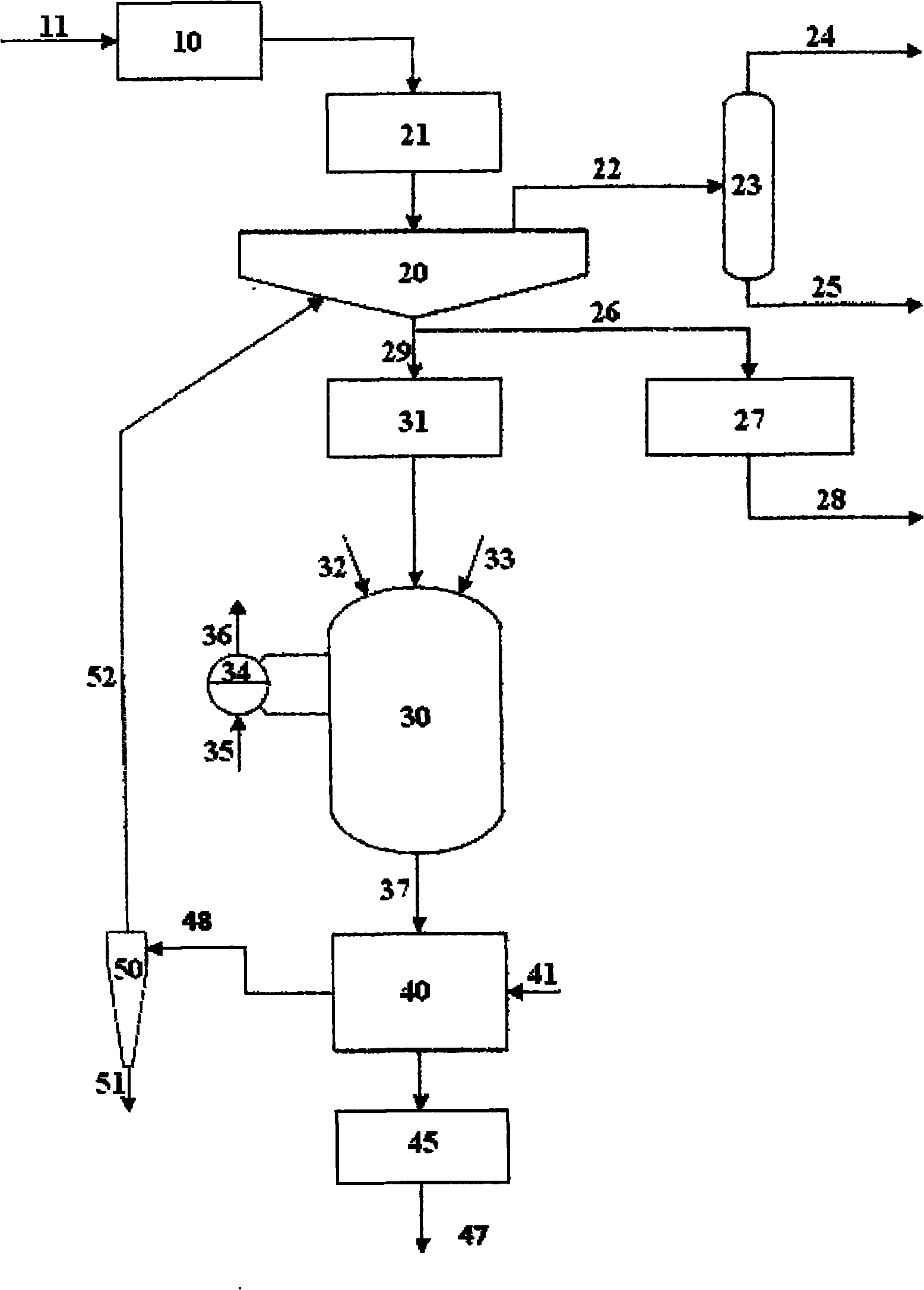

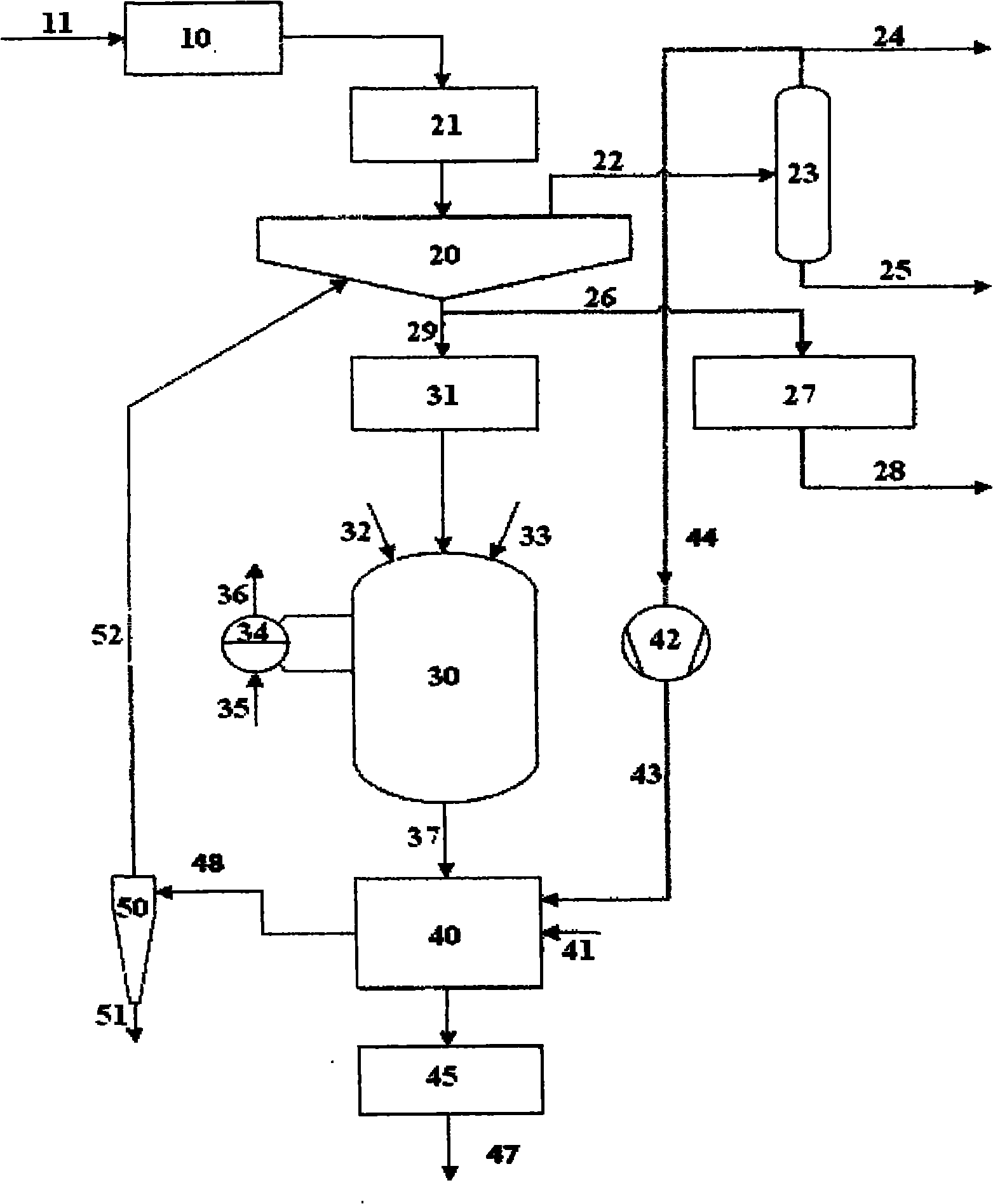

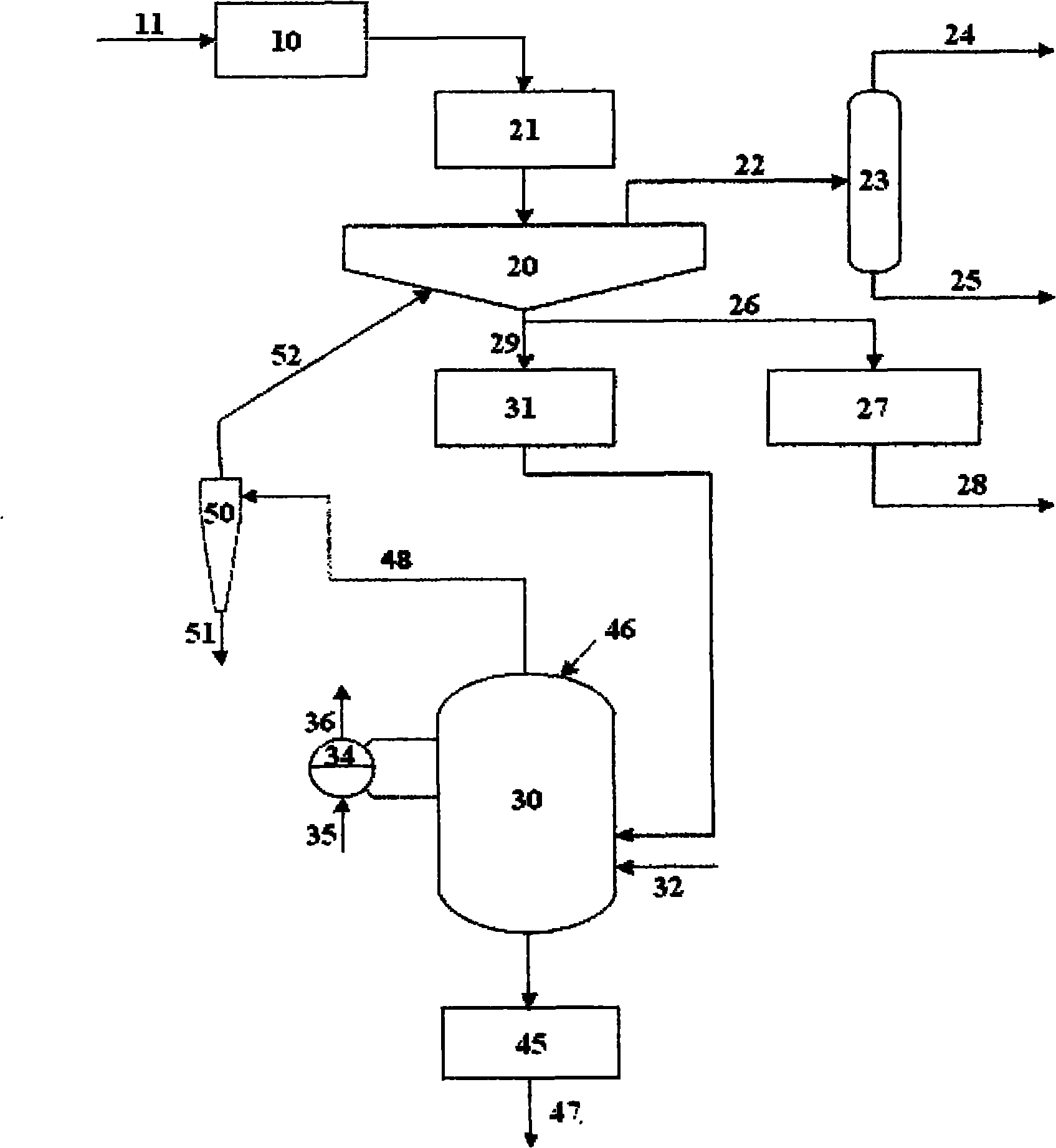

System for preparing solid, liquid and gas products from coal and biomass and method using same

A technology of gas products and solids, which is applied in the manufacture of combustible gases, the preparation of liquid hydrocarbon mixtures, solid fuels, etc., to achieve the effects of improving thermal efficiency of operations and reducing operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] The bituminous coal feedstock was pulverized with known pulverizers to the following particle size distribution (PSD):

[0147] The particle size of 99% by weight of coal is <250 μm;

[0148] The particle size of 100% by weight of coal is <500 μm;

[0149] And it is dried by a known drier until the water content is lower than 12% by weight; the ash content is >1% by weight, and the melting temperature of the ash is <1500° C.; the calorific value of the coal is about 20900 joules / gram. The temperature of the dried coal is lower than 120°C, and the heat source of the dryer comes from the hot gas of the pyrolysis furnace or chilling unit, etc.

[0150] The above pulverized and dried coal is first fed into a known first lock hopper system, which is pressurized to slightly above 35 bar, such as 36 bar or 37 bar, and then fed into a known fluidized bed type pyrolysis furnace for the pyrolysis reaction. The operating pressure of the pyrolysis furnace is about 35 bar and the...

Embodiment 2

[0184] In Example 2, the bituminous coal raw material and its limitations are the same as in Example 1, and the pyrolysis furnace is a fluidized bed type pyrolysis furnace whose operating temperature and pressure are about 450-500° C. and about 40 bar, respectively; on the other hand , the gasifier is an upward gasifier fed with coal-water slurry, such as an E-gas type gasifier, and its operating temperature and pressure are about 1480° C. and about 45 bar, respectively. The residence time of the pulverized and dried coal in the pyrolysis furnace was about 27 minutes.

[0185] About 3 / 4 of the coke from the pyrolysis furnace is fed into the slurry tank at a pressure of about 40 bar to form a water coke slurry with a coke / water volume ratio of about 0.6 / 0.4 in an amount to form coke having the above Water of about three times the amount of water required for the water coke slurry is added to the above-mentioned slurry tank, wherein 2 / 3 of the water becomes high-temperature and ...

Embodiment 3

[0208] The raw coal is a lignite with a water content of 31%, and the calorific value is 19.33MJ / Kg after analysis. The raw coal is pulverized by known pulverizers to the following particle size distribution (PSD):

[0209] 80% by weight of coal have a particle size <250 μm;

[0210] The particle size of 100% by weight of coal is <500 μm;

[0211] And it is dried to a moisture content of less than 8% by weight through a known dryer; the temperature of the dried coal is lower than 150° C., and the heat source of the dryer is hot gas from a pyrolysis furnace or a chilling unit, etc.

[0212] First, the above-mentioned pulverized and dried coal is fed into a known first lock bucket system at a flow rate of 100-120 tons per hour, pressurized to slightly higher than 35 bar, such as 36 bar or 37 bar, and then fed into The pyrolysis reaction is carried out in a known fluidized bed type pyrolysis furnace. The operating pressure of the pyrolysis furnace is about 35 bar and the opera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com