Method for improving forming ability and strength of amorphous alloy by controlling solidifying condition

A technology for controlling solidification and amorphous alloys, applied in the field of bulk amorphous alloy preparation, can solve problems such as huge experimental consumption, and achieve the effects of high strength, improved surface free energy, rapid filling and compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

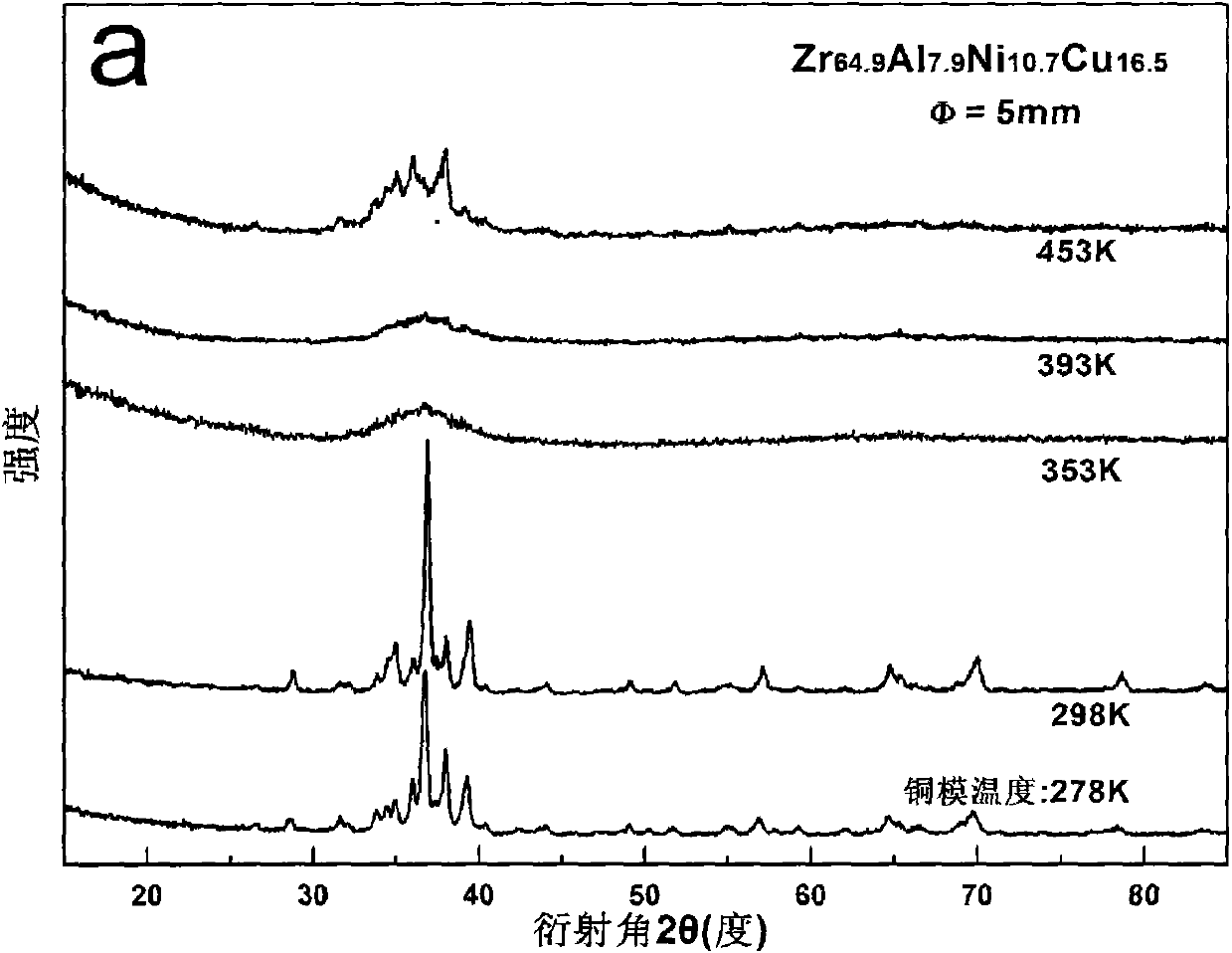

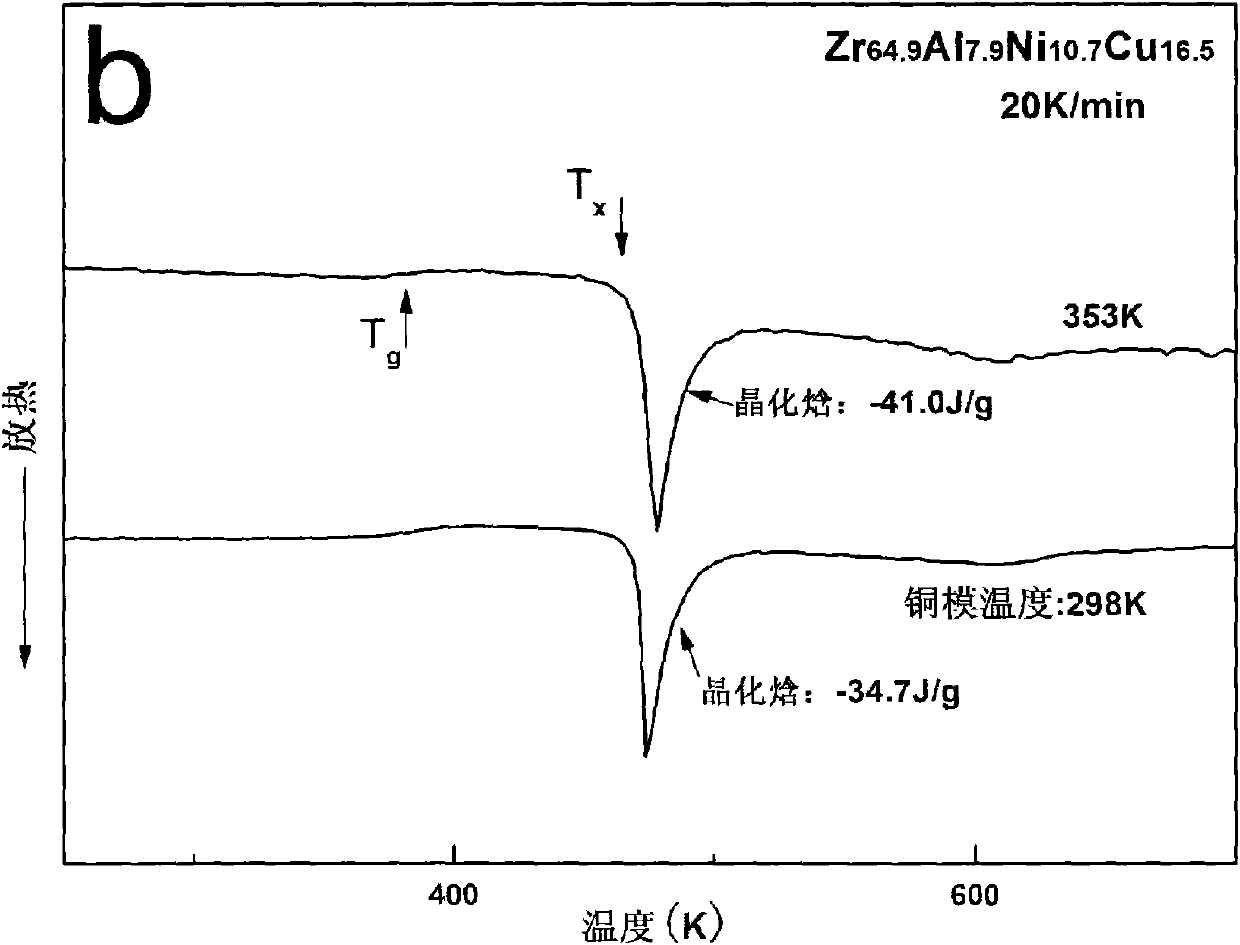

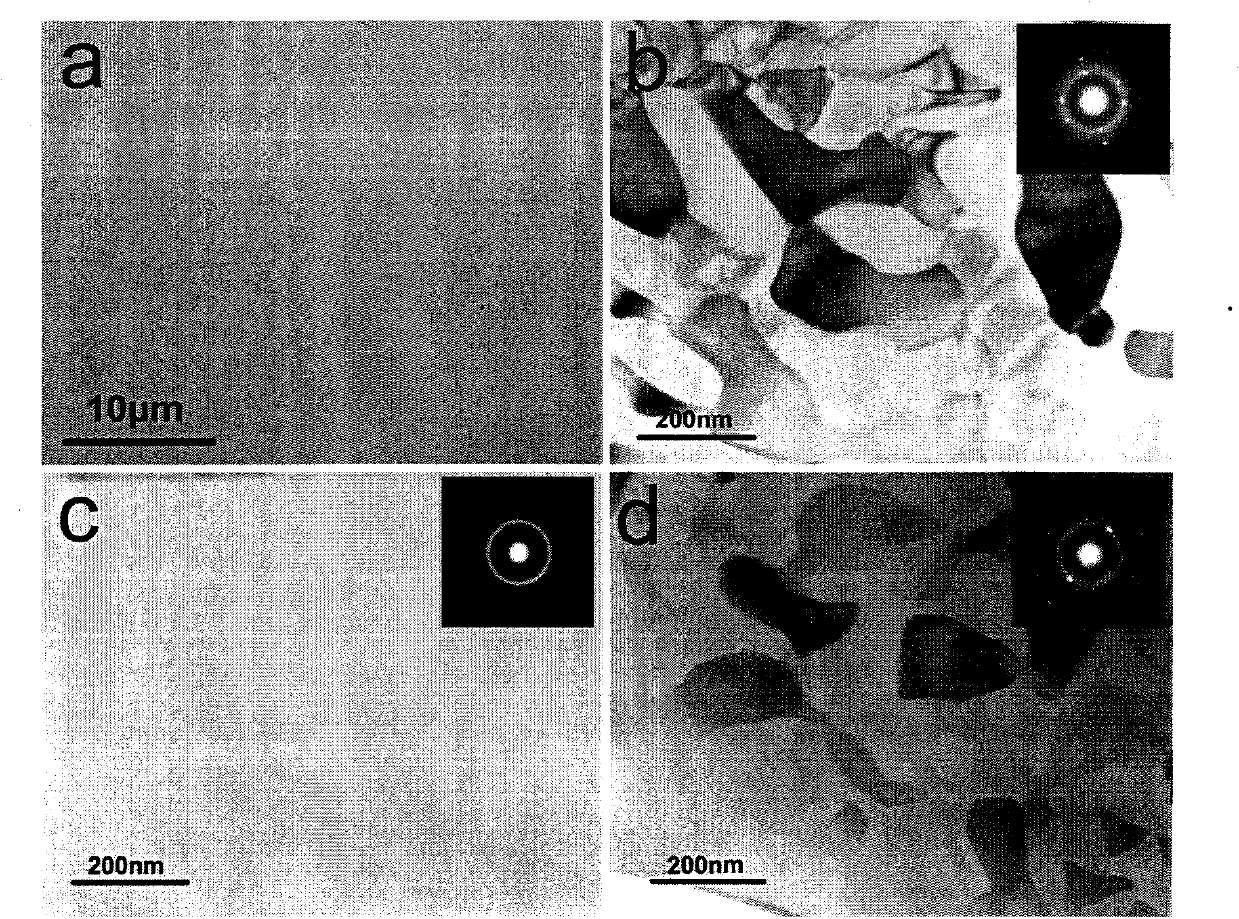

[0023] The selected alloy is Zr-Al-Ni-Cu, and the specific composition is: 64.9% Zr, 7.9% Al, 10.7% Ni, 16.5% Cu (atomic percentage).

[0024] The smelting method of Zr-Al-Ni-Cu master alloy is a conventional technology among the present invention, and the specific process parameters and process of master alloy smelting in this embodiment are as follows: the raw materials used are respectively Zr, Al, Ni, Cu high-purity metal (purity is not high) less than 99.9wt.%); master alloy ingots are melted by electric arc, the working chamber is first evacuated to 10-2 ~ 10-4Pa, and then high-purity argon gas (purity 99.99wt.%) is introduced for melting; melting Before alloying, the Ti metal ingot is first melted, and titanium oxide is formed through oxidation reaction to further reduce the partial pressure of oxygen in the working chamber. In order to ensure that the composition of the alloy ingot is as uniform as possible, each alloy ingot needs to be turned and smelted 3 to 5 times; ...

Embodiment 2

[0029] The difference from Example 1 is:

[0030] The alloy composition is 47% Zr, 37.5% Cu, 7.5% Ag, 8% Al (atomic percentage). The specific process parameters of copper mold casting are as follows: vacuum degree 10-2~10-4Pa, cooling speed 1~10 2K / s, the mold temperature is preheated to 353K. From Figure 4 It can be seen that the X-ray crystalline peak of the sample prepared at a mold temperature of 353K is significantly weakened, and it is basically completely amorphous, indicating that the ability to form amorphous is enhanced. Simultaneously, the compressive breaking strength at room temperature is 2159-2228MPa, which is 4%-8% higher than that of the sample (2073MPa) prepared by mold at room temperature.

Embodiment 3

[0032] The difference from Example 1 is:

[0033] The alloy composition is 62% Zr, 15.4% Cu, 12.6% Ni, 10% Al (atomic percentage). The specific process parameters of copper mold casting are as follows: vacuum degree 10 -2 ~10 -4 Pa, cooling rate 1~10 2 K / s, the mold temperature is preheated to 353K. The amorphous formation ability of the sample prepared at the mold temperature of 353K is enhanced. At the same time, the compressive fracture strength is increased by 7.4% on average compared with the sample prepared by room temperature mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com