Method for preparing single-layer high-activity titanium dioxide thin film

A titanium dioxide, high-activity technology, applied in the coating process of metal materials, etc., can solve the problems that titanium dioxide powder is difficult to make dense and strong films, limit applications, and the photocatalytic efficiency of titanium dioxide cannot be satisfied, etc., to achieve controllable film thickness , enhance the transfer efficiency, combined with a firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The 0.25mm×10mm×30mm titanium sheet was ultrasonically cleaned with absolute ethanol and deionized water respectively, and after vacuum drying at 80°C, a clean titanium sheet without an oxide layer on the surface was obtained. Then, put the clean titanium sheet into an 80 mL stainless steel reaction kettle lined with polytetrafluoroethylene and filled with 40 mL of 10 mM dilute hydrofluoric acid aqueous solution. After the reaction kettle is sealed, put it into an oven for heat treatment at 140°C for 10 hours, take out the reacted titanium sheet, wash it with deionized water and dry it at 80°C to obtain a titanium sheet with a single-layer (001) crystal plane titanium dioxide film formed on the surface .

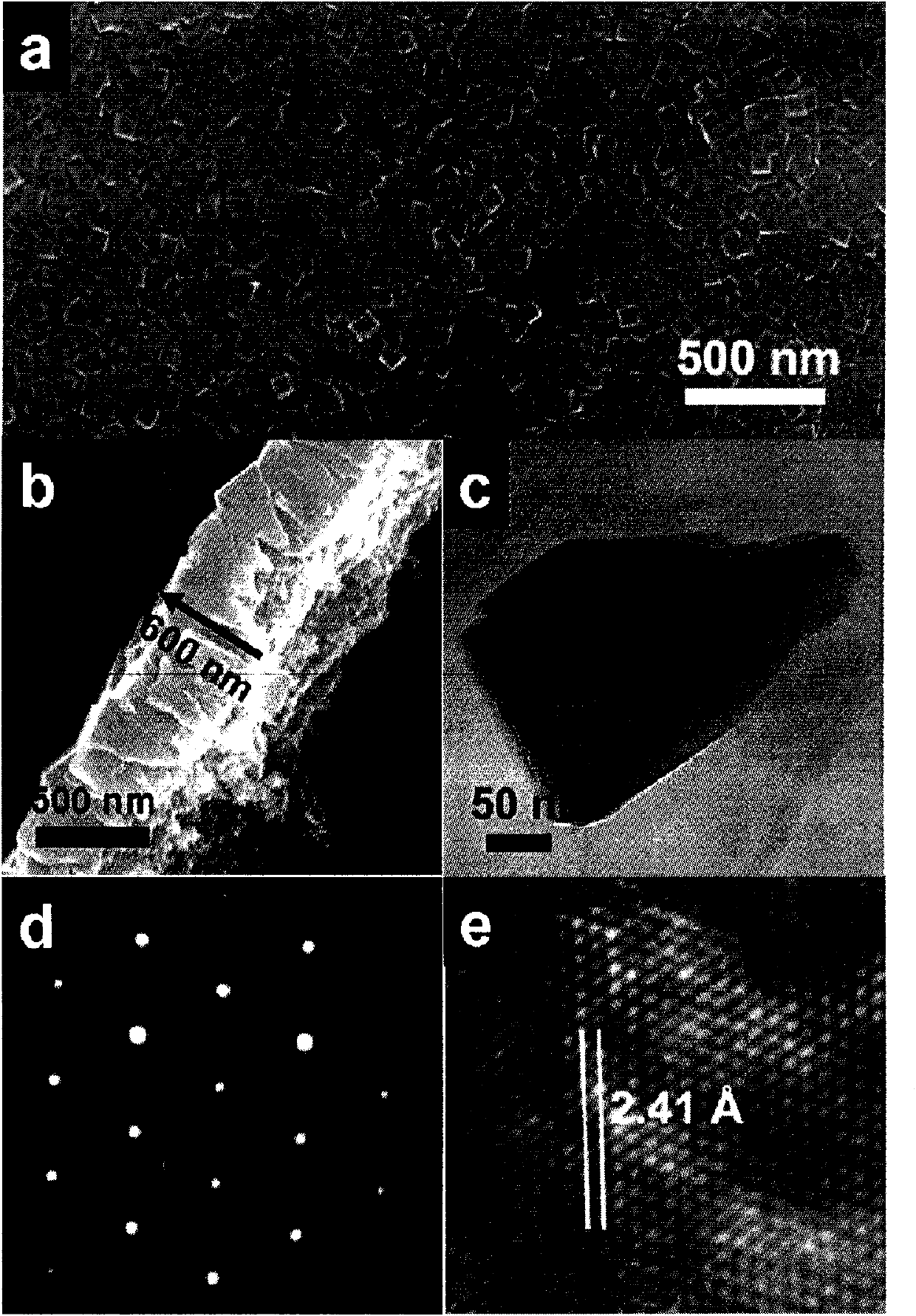

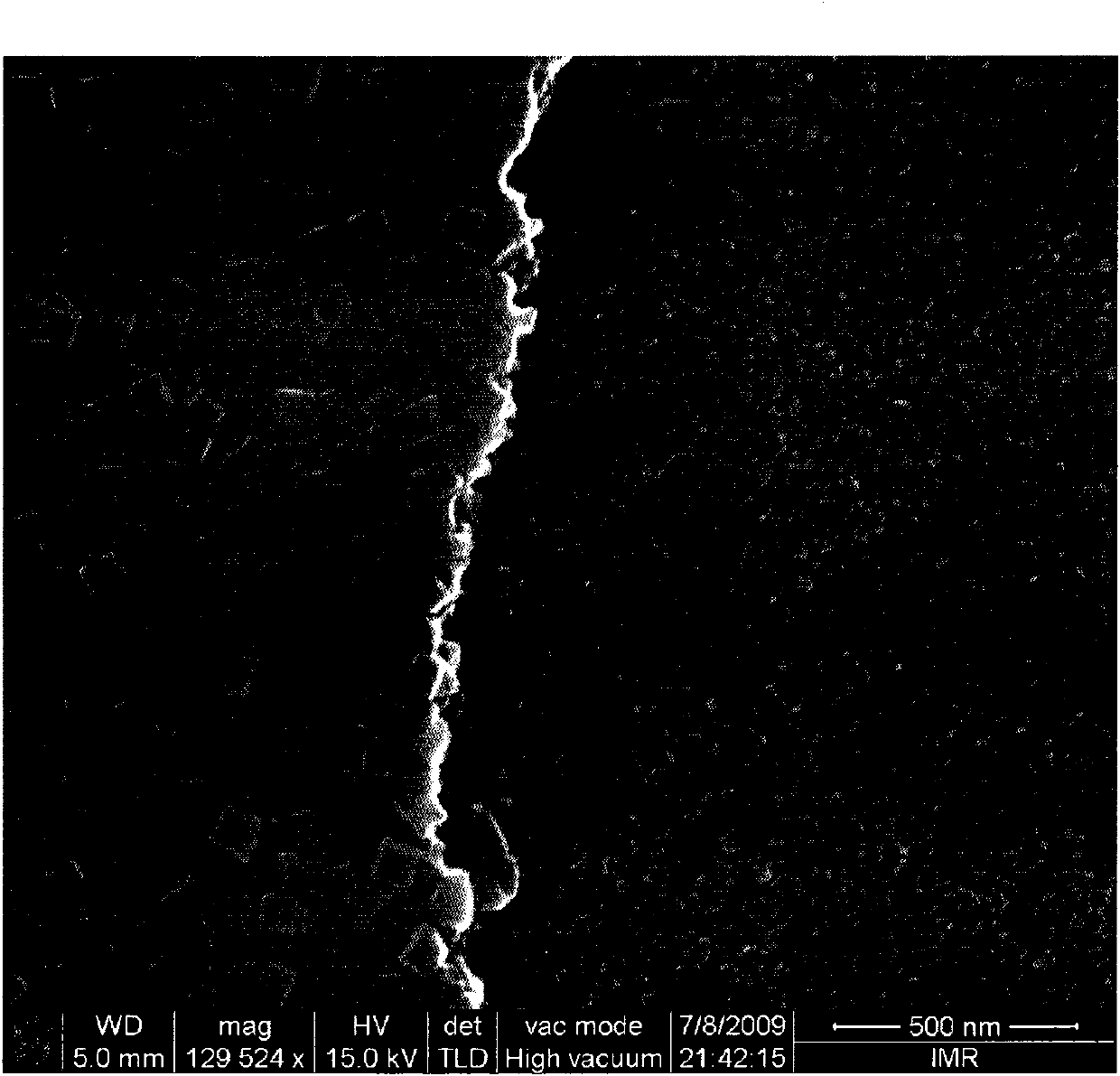

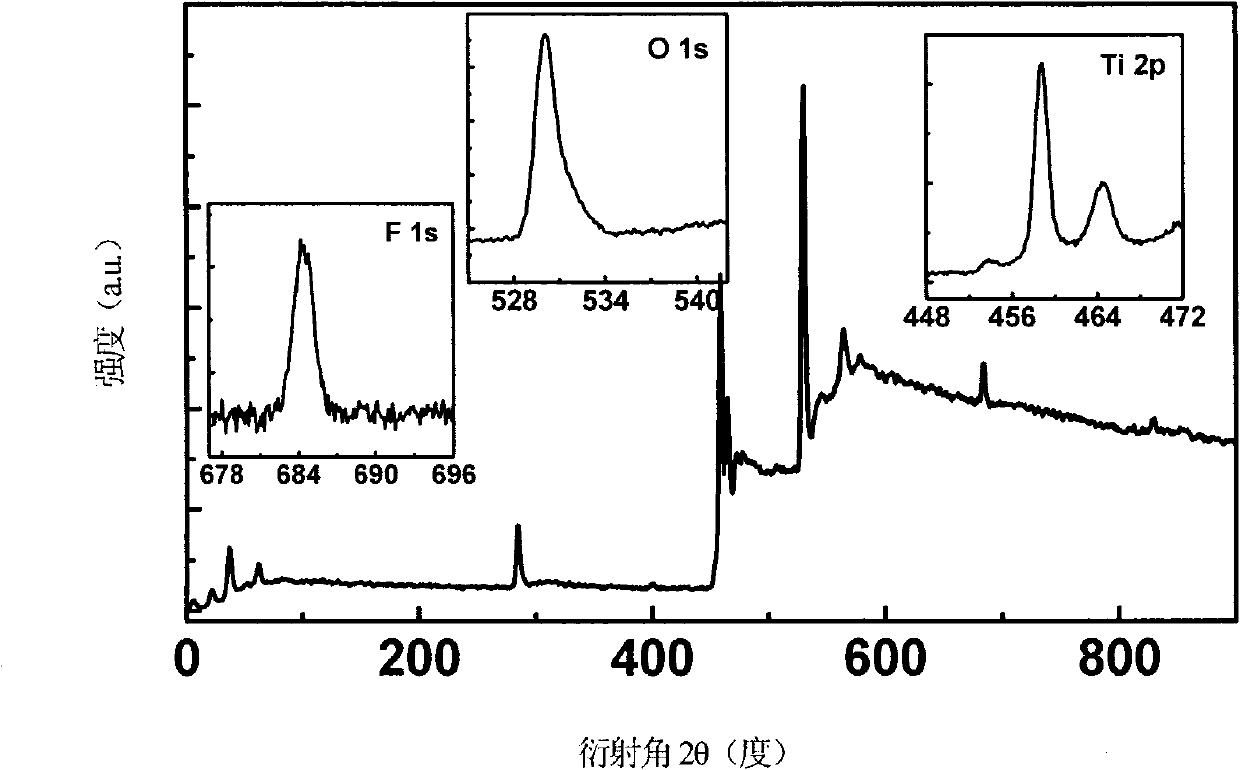

[0029] Such as figure 1 As shown, the exposed surface of the titanium dioxide film formed on the titanium sheet is a highly active (001) crystal plane, the film is composed of tooth-like titanium dioxide crystal particles, the particle size is 130nm, and the film has...

Embodiment 2

[0035] The 0.25mm×10mm×30mm titanium sheet was ultrasonically cleaned with absolute ethanol and deionized water respectively, and after vacuum drying at 80°C, a clean titanium sheet without an oxide layer on the surface was obtained. Then, put the clean titanium sheet into an 80 mL stainless steel reaction kettle lined with polytetrafluoroethylene and filled with 40 mL of 8 mM dilute hydrofluoric acid aqueous solution. After the reaction kettle is sealed, put it into an oven for heat treatment at 120°C for 10 hours, take out the reacted titanium sheet, wash it with deionized water and dry it at 80°C to obtain a titanium sheet with a single-layer (001) crystal plane titanium dioxide film formed on the surface .

[0036] Such as Figure 6 As shown, the titanium dioxide (001) crystal film synthesized under this condition, the obtained film is titanium dioxide crystal, the size of the titanium dioxide crystal particle is 300nm, the film is composed of titanium dioxide of anatase ...

Embodiment 3

[0038] Ultrasonic cleaning of 0.2 g of titanium ingots with absolute ethanol and deionized water respectively, followed by vacuum drying at 80° C., to obtain clean titanium ingots without an oxide layer on the surface. Then, put the clean titanium block into an 80 mL stainless steel reaction kettle lined with polytetrafluoroethylene and filled with 40 mL of 15 mM dilute hydrofluoric acid aqueous solution. After the reaction kettle is sealed, put it into an oven for heat treatment at 140°C for 15 hours, take out the reacted titanium block, wash it with deionized water and dry it at 100°C to obtain a titanium block with a single-layer (001) crystal plane titanium dioxide film formed on the surface .

[0039] Such as Figure 7As shown, the titanium dioxide (001) crystal film synthesized under this condition, the obtained film is titanium dioxide crystal, the size of the titanium dioxide crystal particle is 120nm, the film is composed of titanium dioxide of anatase and rutile pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com