Method for heating cane juice by using waste heat of flue gas of boiler

A boiler flue and flue gas technology, applied in lighting and heating equipment, applications, cane sugar production, etc., can solve the problem of not mentioning heating cane juice, etc., and achieve the effects of significant economic benefits, low operating costs, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

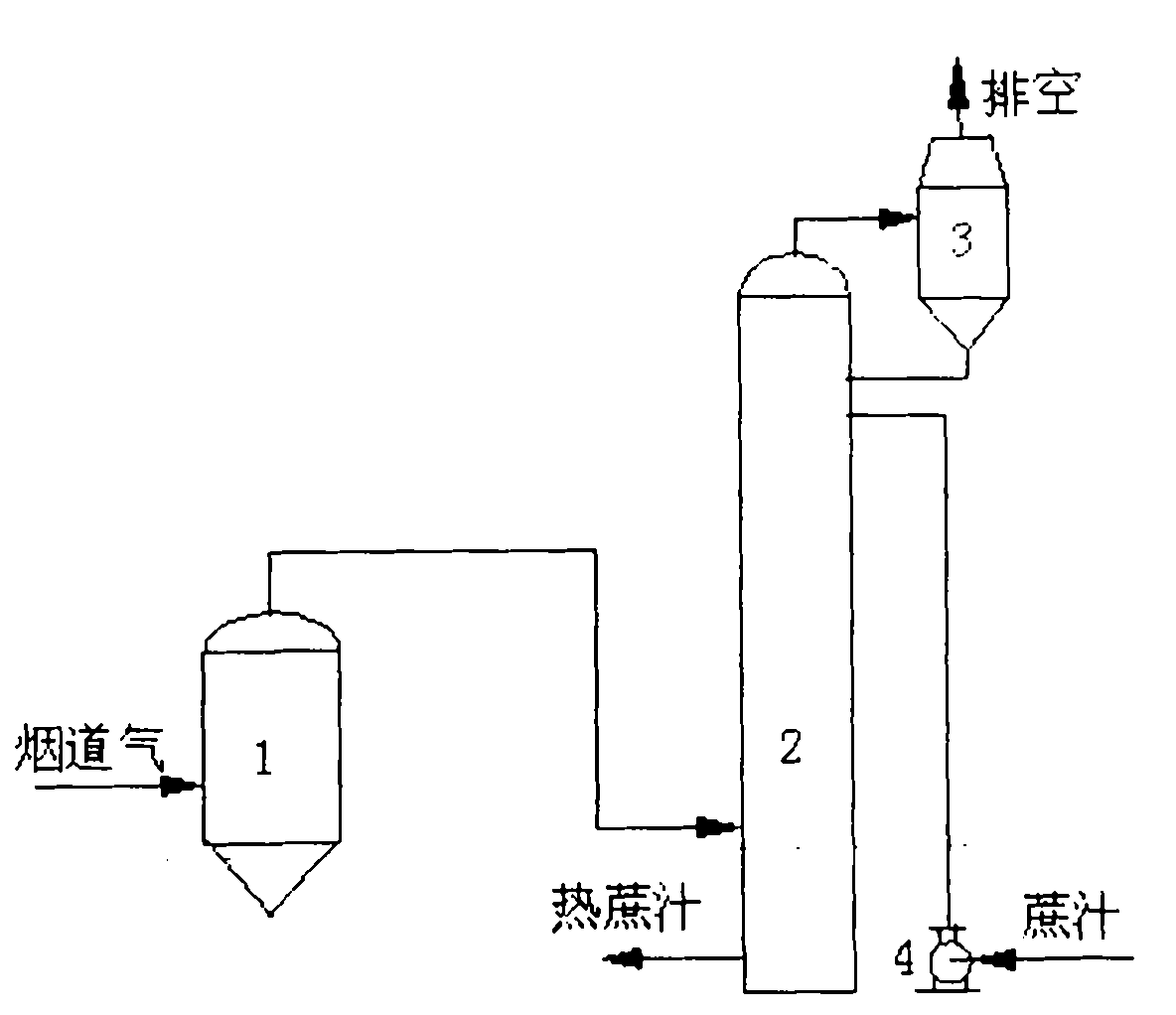

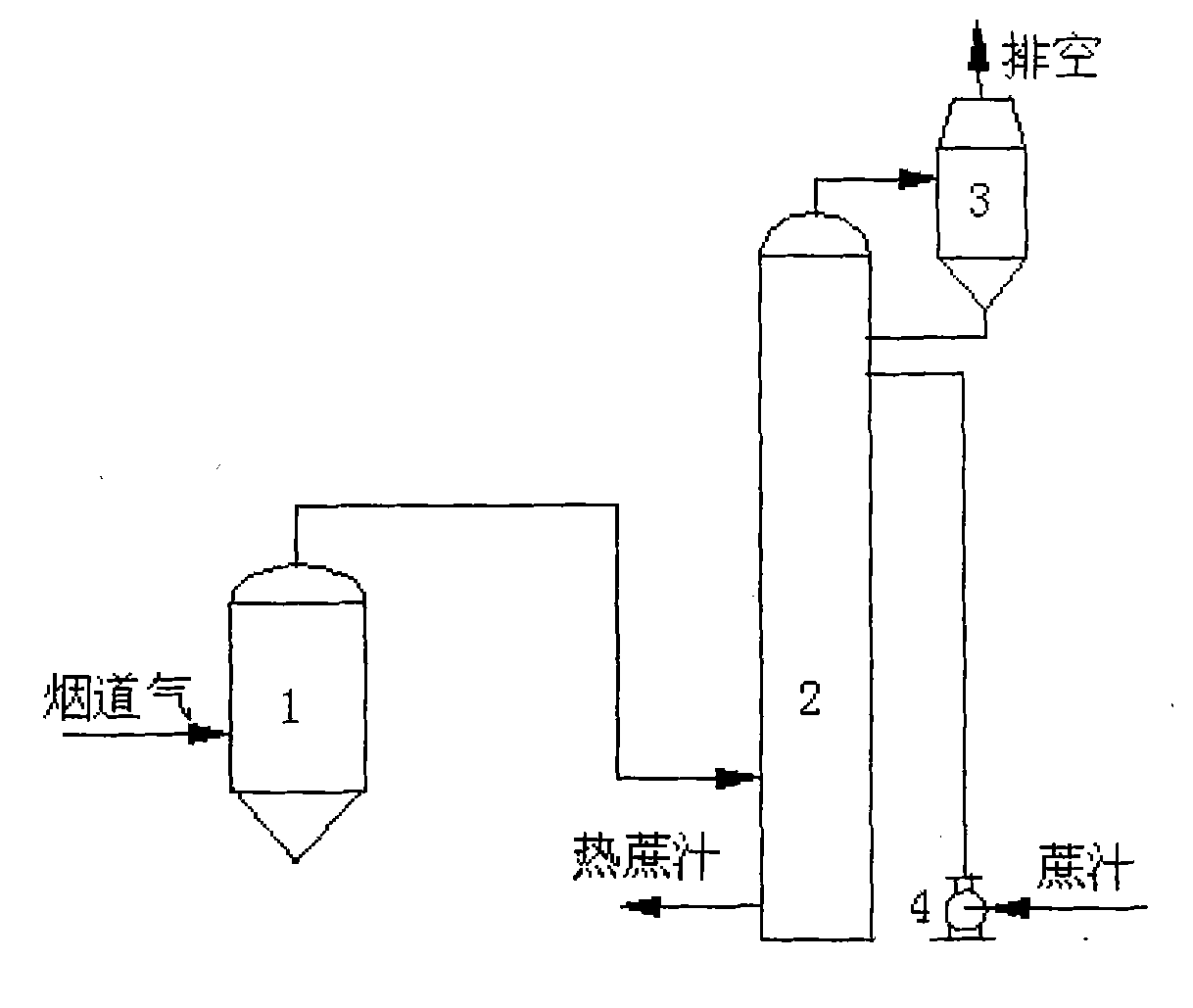

[0018] Boiler flue gas enters the wet flue gas scrubber 1 and directly contacts with hot water to remove dust from the flue gas. The hot water for washing is filtered and recycled, and the lost part is replaced by hot water above 90°C. The flue gas after dedusting enters the spray type direct contact heat exchange tower 2, and directly contacts with the sprayed neutralized sugarcane juice to heat the sugarcane juice to 100°C, and the cooled flue gas enters the gas-liquid separator through the top of the tower 3. After separating the entrained sugarcane juice, it is discharged into the air from the top of the gas-liquid separator 3, and the separated sugarcane juice flows back to the jet-type direct contact heat exchange tower 2 through the bottom of the gas-liquid separator 3. After neutralizing by sulfur fumigation at 60°C The sugarcane juice is sent to the cane juice inlet of the jet direct contact heat exchange tower 2 by the cane juice pump 4, and the heated cane juice goes...

Embodiment 2

[0020] Boiler flue gas enters the wet flue gas scrubber 1 and directly contacts with hot water to remove dust from the flue gas. The hot water for washing is filtered and recycled, and the lost part is replaced by hot water above 90°C. The flue gas after dedusting enters the jet type direct contact heat exchange tower 2, and directly contacts with the sprayed neutralized sugarcane juice to heat the sugarcane juice to 60°C, and the cooled flue gas enters the gas-liquid separator through the top of the tower 3. After separating the entrained sugarcane juice, it is discharged into the air from the top of the gas-liquid separator 3, and the separated sugarcane juice flows back to the jet-type direct contact heat exchange tower 2 through the bottom of the gas-liquid separator 3. After neutralization by sulfur fumigation at 25°C The cane juice is sent to the cane juice inlet of the jet direct contact heat exchange tower 2 by the cane juice pump 4, and the heated cane juice goes to th...

Embodiment 3

[0022] The boiler flue gas enters the dry flue gas dust collector 1 to remove the dust in the flue gas, and the flue gas after dust removal enters the jet-type direct contact heat exchange tower 2, and directly contacts with the sprayed neutralized cane juice to remove the cane The juice is heated to 100°C, and the cooled flue gas enters the gas-liquid separator 3 through the top of the tower, the entrained sugarcane juice is separated and discharged from the top of the gas-liquid separator 3 to the air, and the separated sugarcane juice passes through the gas-liquid separator 3. The bottom flows back to the jet-type direct contact heat exchange tower 2. The cane juice neutralized by sulfur fumigation at 60°C is sent by the cane juice pump 4 to the cane juice inlet of the jet-type direct contact heat exchange tower 2. The heated cane juice is sprayed direct contact with the outlet of the lower part of the heat exchange tower 2 to settle the follow-up section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com