Bamboo mosaic and manufacturing method thereof

A bamboo mosaic and production method technology, applied in decorative arts, covering/lining, construction, etc., can solve the problems of unusable, low utilization rate of bamboo materials, easy to fall off, etc., to save energy, broaden the scope of use, and have good thermal insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

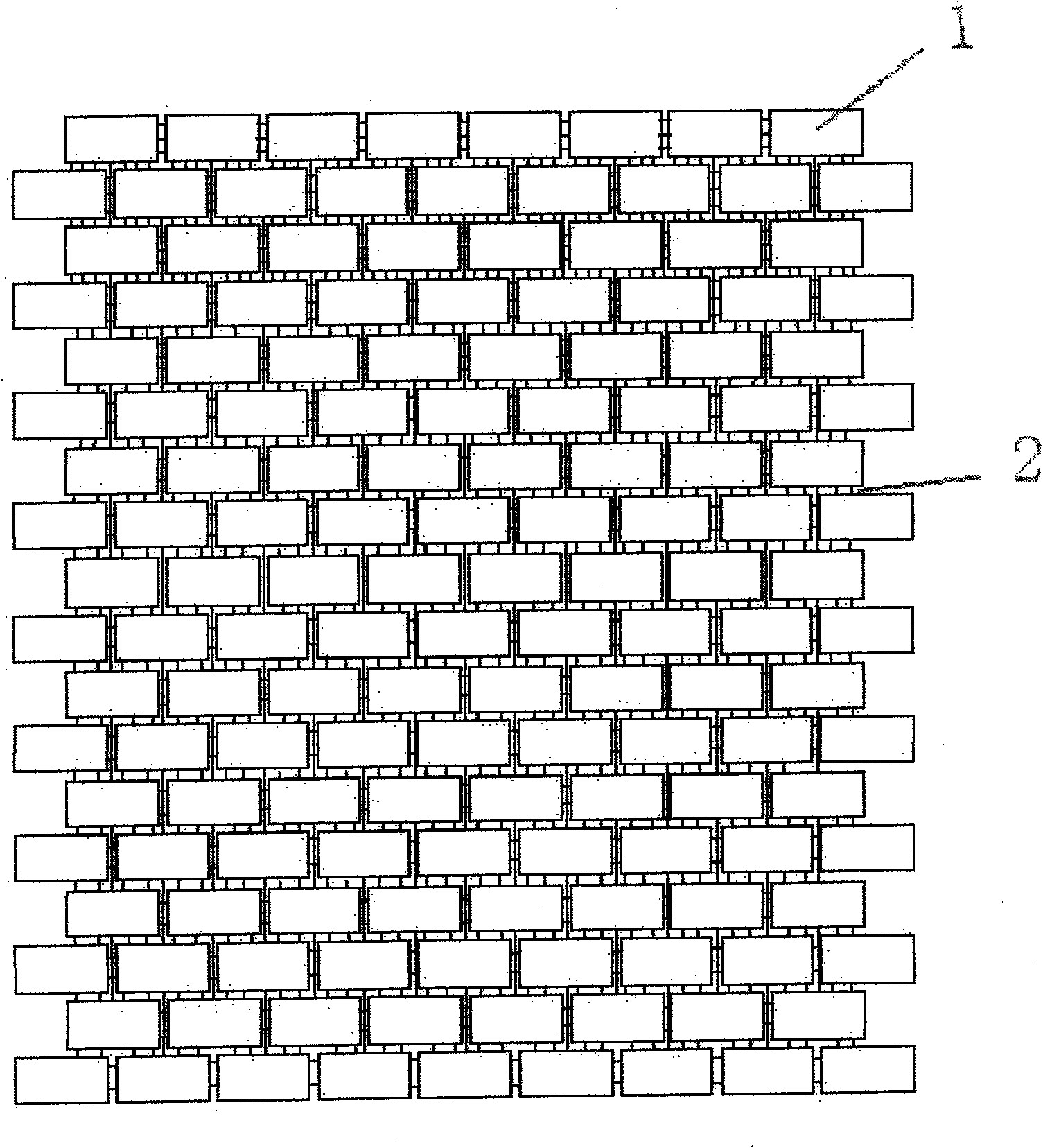

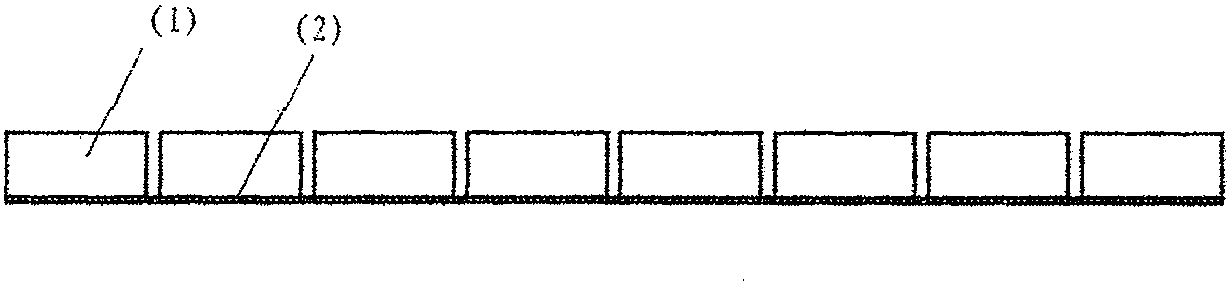

[0022] refer to figure 1 , 2 The bamboo mosaic will be sterilized at a temperature of 150-200°C for 3-6 hours. Dry in the drying room for 80-100 hours, bamboo particles (1) with a moisture content of 8-12% or less are 5mm thick and 15*15*8mm in size. The fiberglass net (2) 305mm*305mm is pasted on the bamboo particle group and dries after, brushing paint (UV original paint). Inspection qualified storage.

Embodiment 2

[0024] refer to figure 1 , 2 The bamboo mosaic will be sterilized at a temperature of 150-200°C for 3-6 hours. The time of drying in the drying room is 80-100 hours, and the bamboo particles (1) with a moisture content of 8-12% have a thickness of 8m and a specification of 23mm*23mm*8mm. Fiberglass net (2) 305mm*305mm is pasted on the bamboo particle group and dries after, brushing paint (UV original paint). Inspection qualified storage.

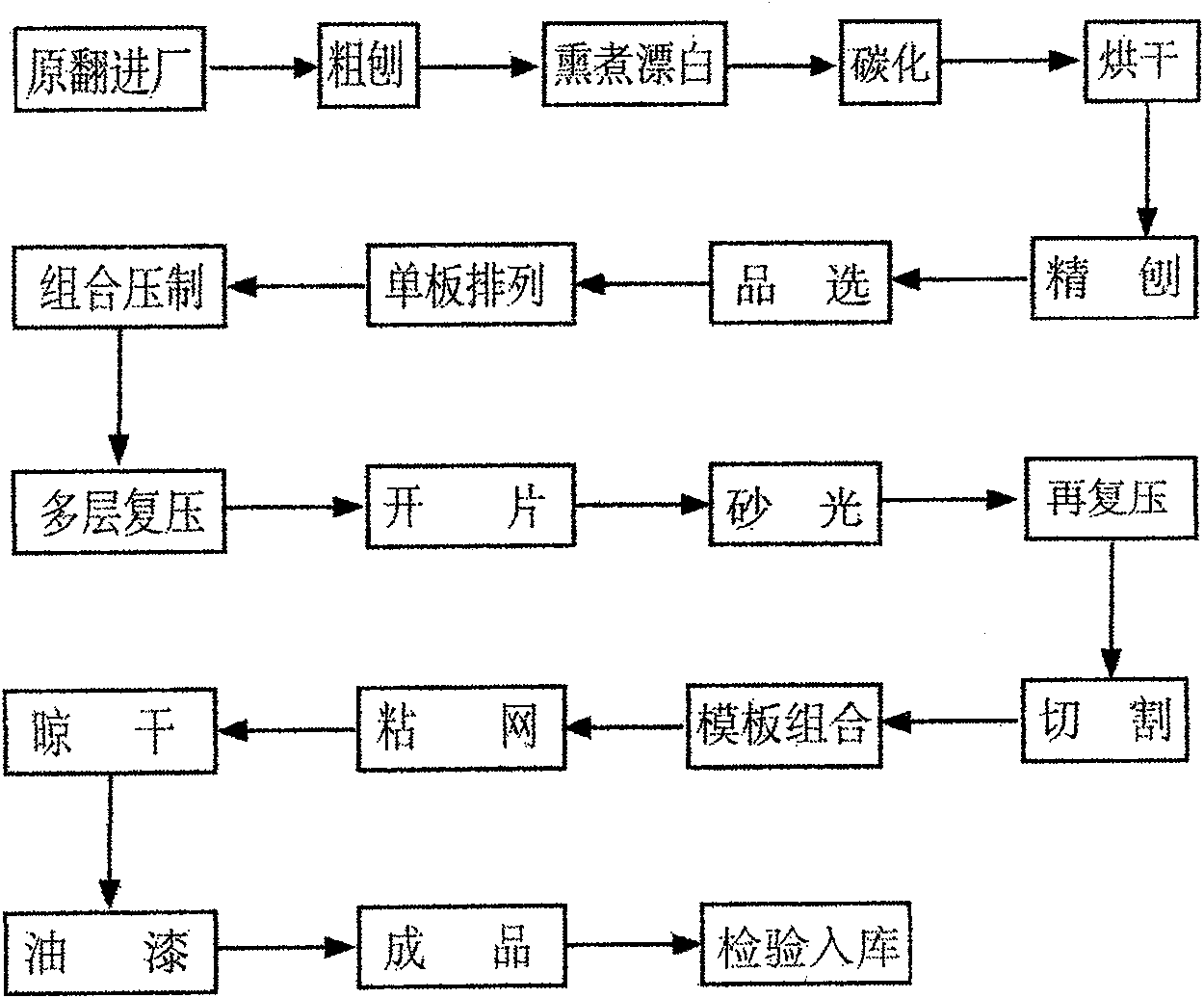

[0025] Concrete producing method of the present invention, step are as follows:

[0026] 1. The selected material is raw bamboo with a diameter of more than 80mm.

[0027] 2. The inspection is the coarse and subdivided grade of the original bamboo diameter.

[0028] 3. After rough processing, the green and bark are removed.

[0029] 4. Sterilize at 150-200°C in a carbonization furnace for 3-6 hours.

[0030] 5. The sterilized bamboo sticks are bleached and boiled at 120° C. for 4-6 hours.

[0031] 6. Dry the treated bamboo strips in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com