Array of graphene-based nano-scale point sources

A nanoscale, point light source technology, applied in the field of arrays of nanoscale point light sources, can solve the problems of difficult control of carbon nanotube manufacturing and integration, difficult light source technology, etc., achieve good light intensity control function, and improve light source irradiation range , the effect of high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

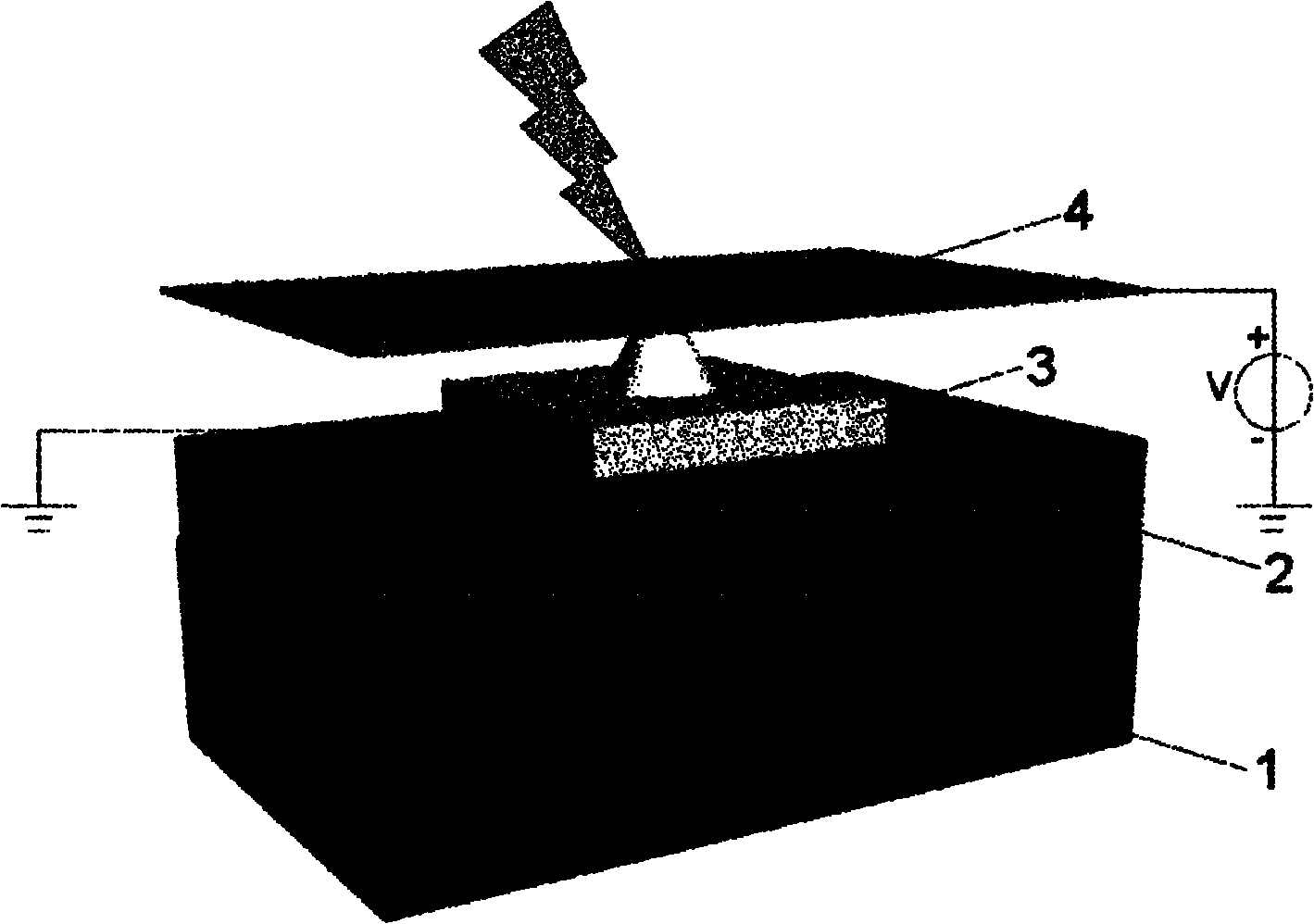

Embodiment 1

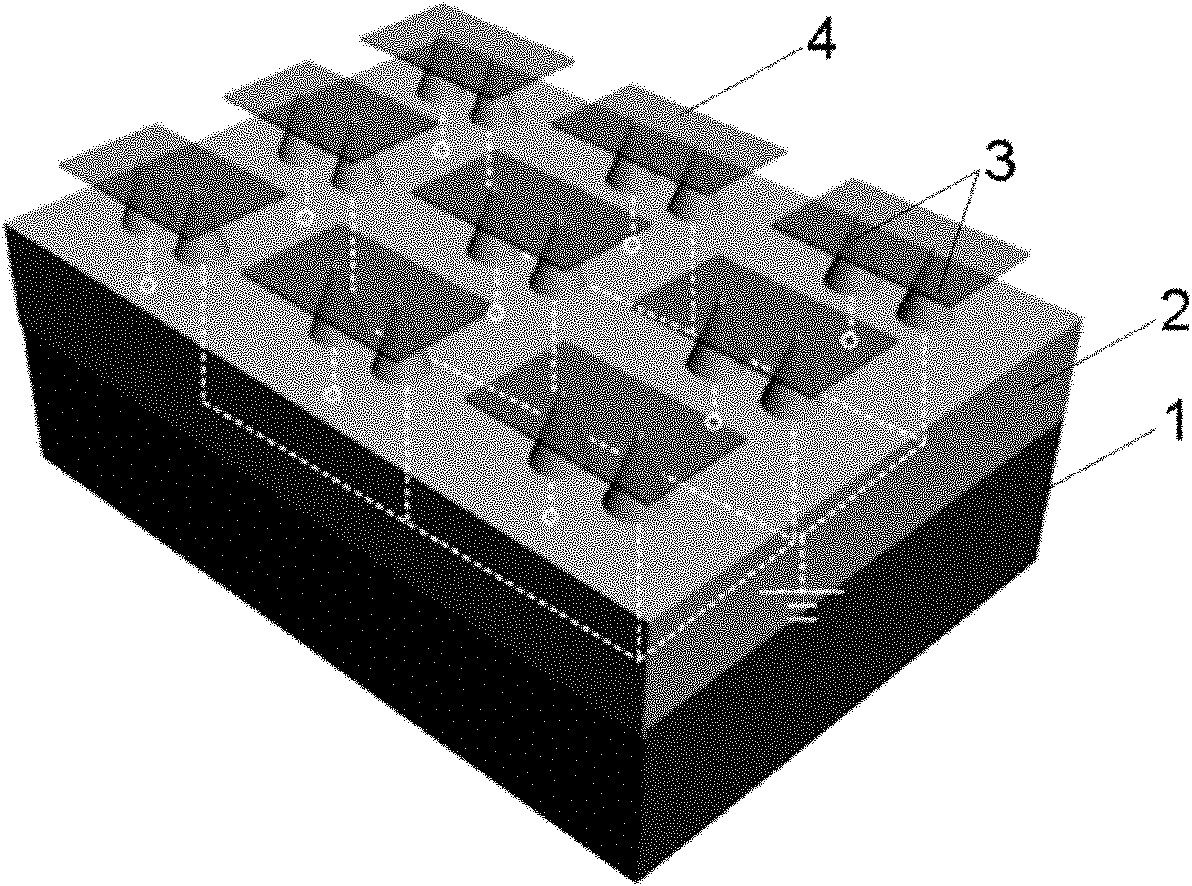

[0020] For the manufacturing process of the point light source array with node single electrode structure, please refer to Figure 4 .

[0021] 1. Chemical vapor deposition (CVD) dielectric layer silicon dioxide;

[0022] 2. The photolithographic dielectric layer, the photolithographic pattern is the pattern of the metal interconnection line inside the dielectric layer;

[0023] 3. Depositing metal interconnection lines: deposit excess metal by evaporation or sputtering, and chemical mechanical polishing (CMP) to smooth the surface;

[0024] 4. Chemical vapor deposition (CVD) dielectric layer silicon dioxide;

[0025] 5. The photolithographic dielectric layer, the photolithographic patterns are metal electrodes and through-hole structures;

[0026] 6. Deposit and polish metal to form electrodes and through-hole structures, the method is the same as 3;

[0027] 7. Etching the dielectric layer, so that the metal electrode has a certain height of protrusion relative to the di...

Embodiment 2

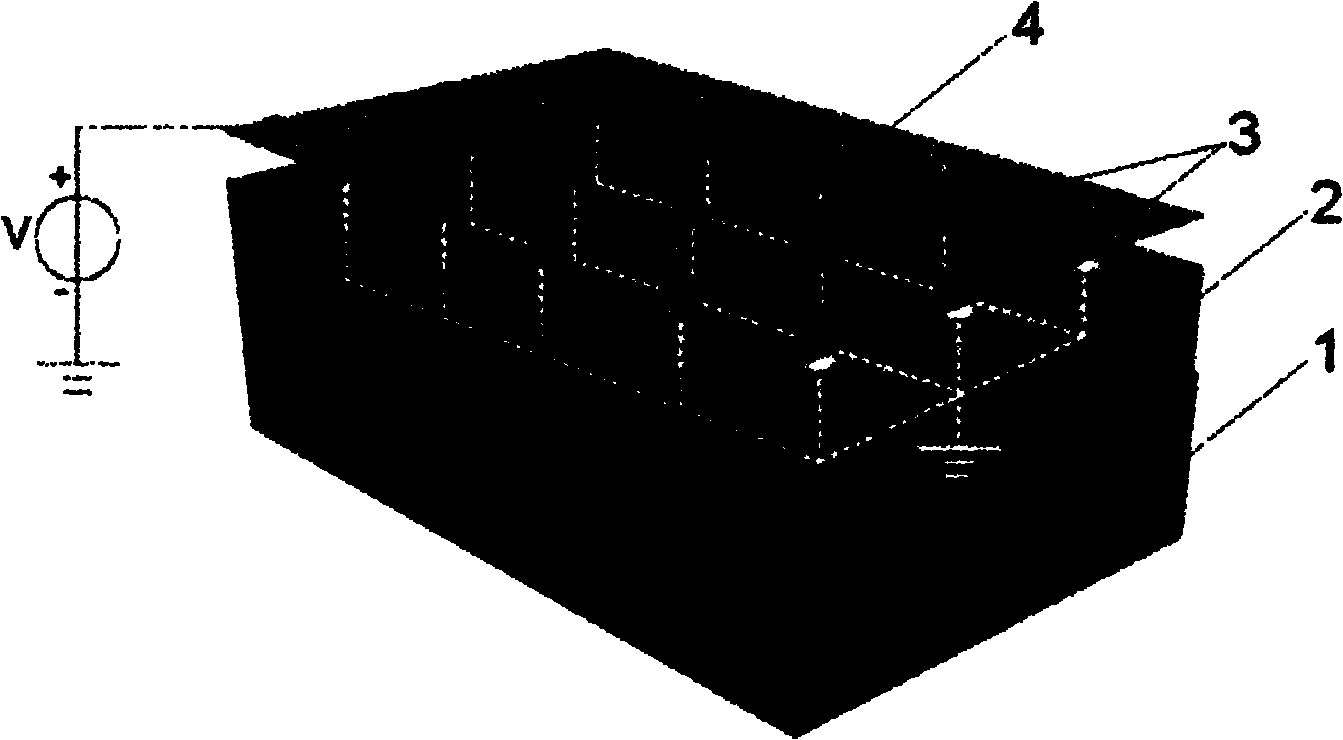

[0033] Specific implementation of node double electrode array structure

[0034] The manufacturing process flow of the point light source array with the node double electrode structure is similar to that of the previous embodiment, see Figure 4 , after the graphene is transferred to the top of the metal electrode, the graphene etching process is added, and the specific process is as follows:

[0035] 1. Chemical vapor deposition (CVD) dielectric layer silicon dioxide;

[0036] 2. The photolithographic dielectric layer, the photolithographic pattern is the pattern of the metal interconnection line inside the dielectric layer;

[0037] 3. Depositing metal interconnection lines: deposit excess metal by evaporation or sputtering, and chemical mechanical polishing (CMP) to smooth the surface;

[0038] 4. Chemical vapor deposition (CVD) dielectric layer silicon dioxide;

[0039] 5. The photolithographic dielectric layer, the photolithographic patterns are metal electrodes and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com