Method for processing a gas for reducing the carbon dioxide content thereof

A carbon dioxide, gas treatment technology, applied in the field of gas treatment to reduce its carbon dioxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] This example relates to the preparation of rare earth metal-based compounds useful in the methods of the invention.

[0087] Four compounds were prepared, the compositions of which are given in Table 1 below.

[0088] Table 1

[0089] compound

CeO 2 (wt%)

La 2 o 3 (wt%)

ZrO 2 (wt%)

PR 6 o 11 (wt%)

SBET (1) (m 2 / g)

Example 1-A

90

0

5

5

70

Example 1-B

80

3

10

7

45

Example 1-C

90

5

0

5

73

Example 1-D

86

4

10

0

73

[0090] (1) This is the specific surface area of the composition at the end of the preparation given in the examples.

[0091] The preparation of various compounds is given below.

Embodiment 1-A

[0093] This example illustrates the formula CeO 2 -ZrO 2 -Pr 6 o 11 The preparation of mixed oxides having the composition in Table 1 and obtained by a process of the type described in the above-mentioned EP-A-906244 can be found in this document.

[0094] The ceric nitrate solution (obtained according to document FR-A-2 570 087) (by adding NH 4 OH is pre-neutralized so that r=-0.22), praseodymium nitrate solution and zirconyl nitrate solution (satisfying OH - / Zr molar ratio = 1.17) are mixed in the stoichiometric ratio required to produce the above-mentioned mixed oxide.

[0095] r represents the degree of neutralization of the cerium solution defined by the following formula:

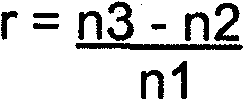

[0096] r = n 3 - n 2 n 1

[0097] where n1 represents the total number of moles of Ce(IV) present in the solution after neutralization, and n...

Embodiment 1-B

[0102] This example illustrates the formula CeO having the composition in Table 1 2 -ZrO 2 -La 2 o 3 -Pr 6 o 11 Preparation of mixed oxides.

[0103] The operation mode is the same as that of Example 1-A, and lanthanum nitrate and other precursors are added in addition. The final calcination was carried out at 850° C. for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com