Method of forming nanocluster-comprising dielectric layer and device comprising such layer

A dielectric layer, dielectric technology, applied in nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve the problems of troublesome and expensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

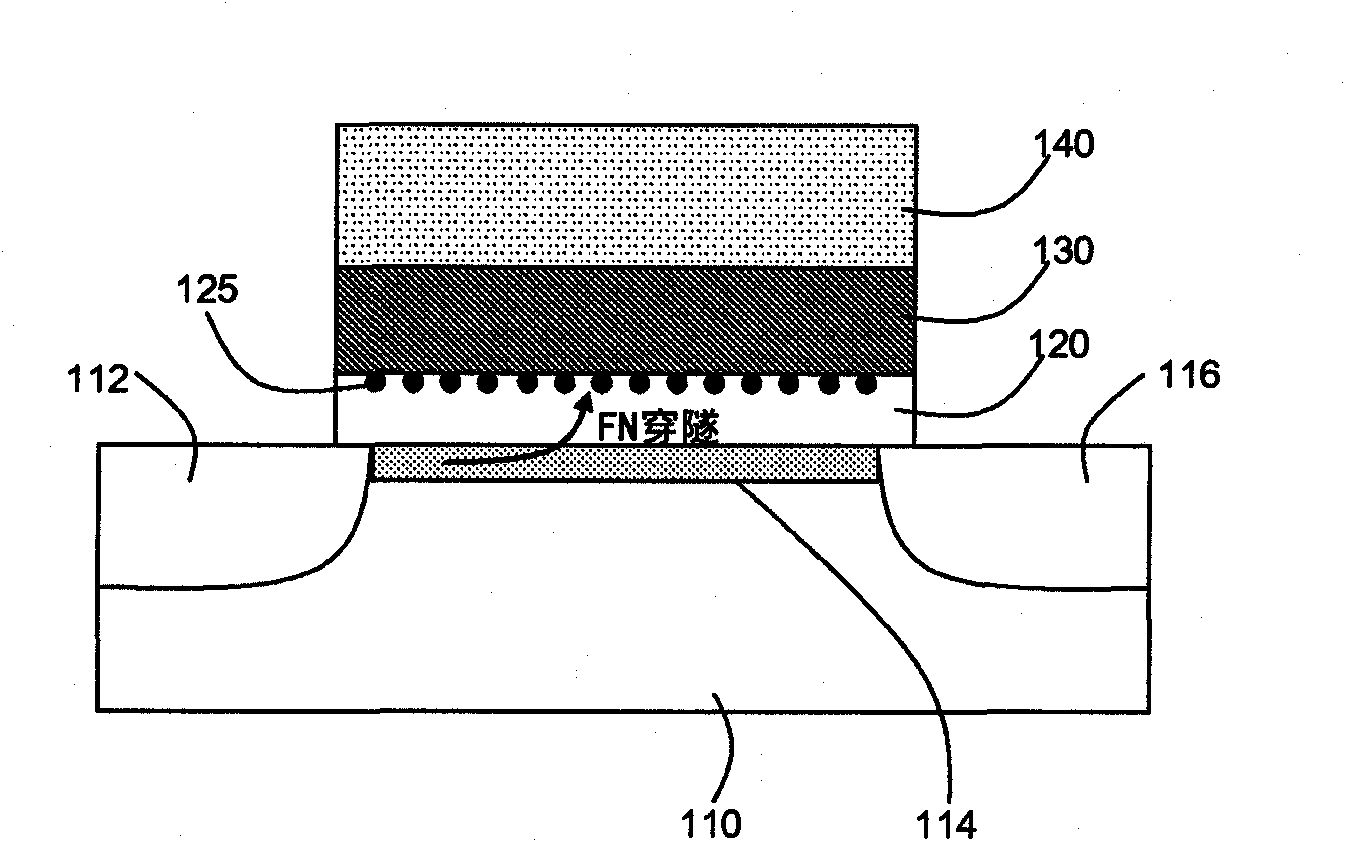

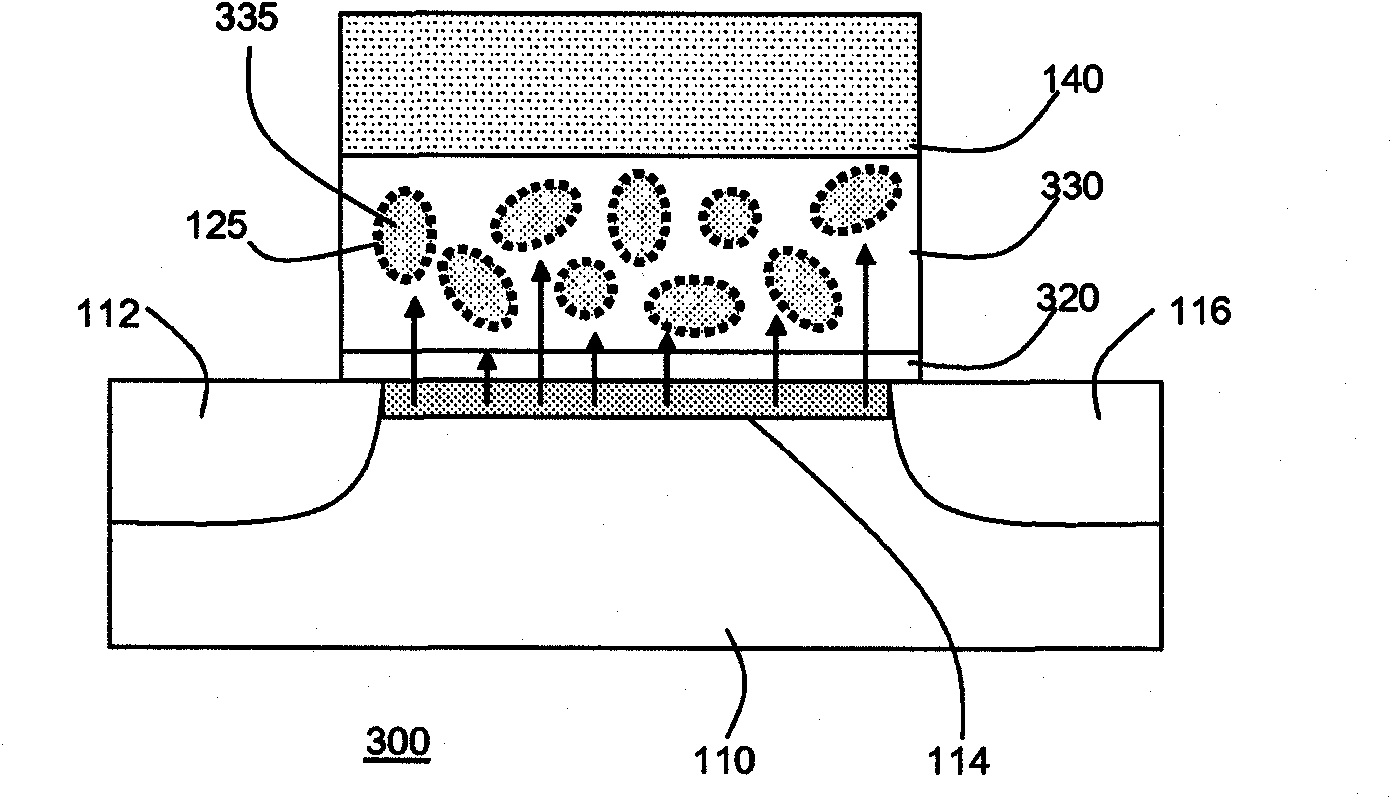

[0040] It should be understood that the drawings in the specification are schematic diagrams only and are not shown to scale. It should also be understood that in the drawings or descriptions in the specification, the same reference numerals are used for similar or identical parts.

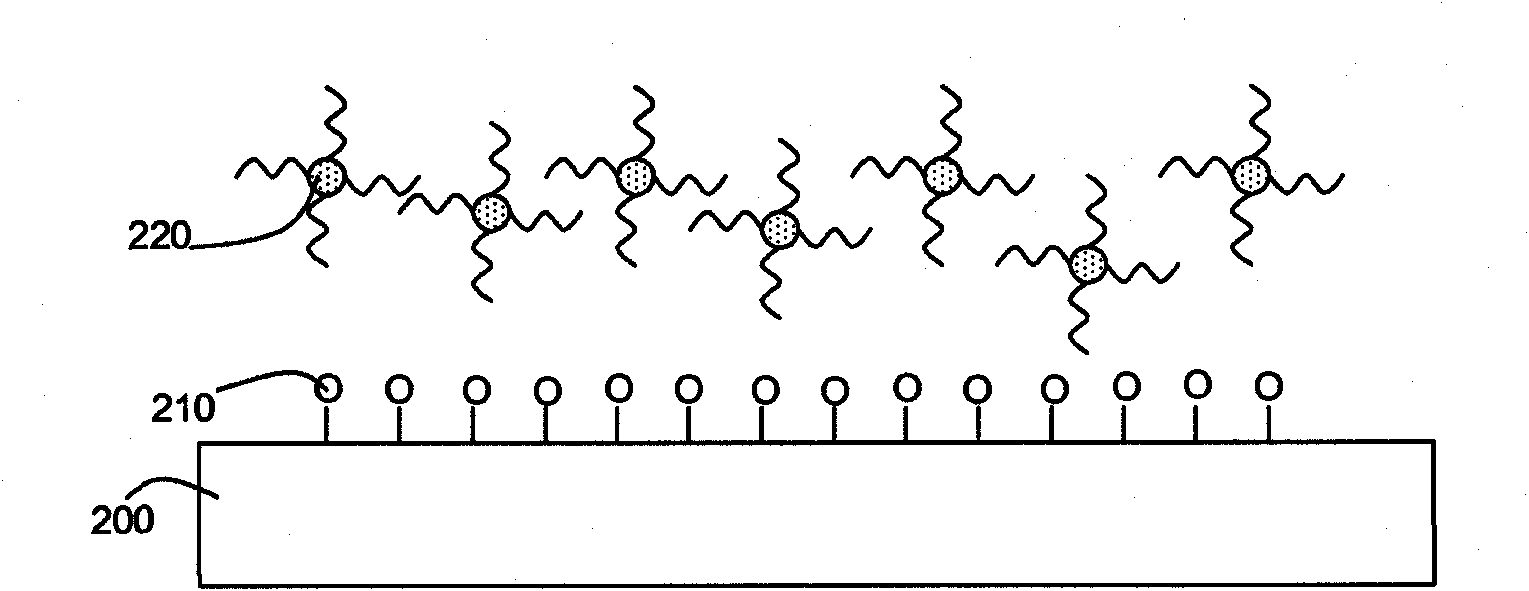

[0041] Figure 2a-Figure 2f A schematic diagram of forming a dielectric layer using an atomic layer deposition (ALD) process. exist Figure 2a Among them, a functional substrate 200 has a surface 210 with hydroxyl groups. A dielectric precursor material 220 comprising a reactive compound, such as a metal ion surrounded by organic ligands or other suitable substituents such as halides, is pulsed over the surface 210 of the functional substrate 200 .

[0042] Such as Figure 2b As shown, this will cause a chemical reaction therein, and the substituents removed from the dielectric precursor material 220 will be replaced by a bridge between the metal ions in the dielectric precursor material 220 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com