Low-temperature diffusion welding method for metal materials

A diffusion welding and metal material technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problem of low joint strength, shorten the time of heating and cooling, reduce production costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Low-temperature diffusion welding of nano-copper on its own surface.

[0025] (1) Preparation of raw materials: T2 copper plate is selected as the model raw material for nano-surface low-temperature diffusion welding, and one side of the copper plate is polished with metallographic sandpaper to obtain a surface with a smoothness that meets the requirements for use.

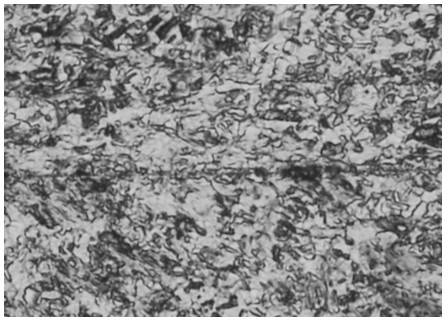

[0026] (2) Self-surface nano-treatment: use the dynamic rolling process at liquid nitrogen temperature to carry out self-surface nano-treatment, install the copper plate on the dynamic rolling surface nano-processing equipment, add liquid nitrogen to cool, and perform dynamic rolling treatment, and finally , a 0.4 mm thick nanostructured layer was obtained on the surface of the copper plate.

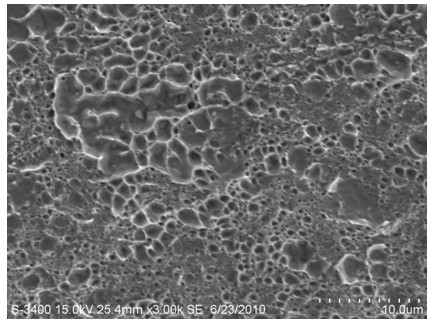

[0027] (3) Diffusion welding at constant temperature and pressure: Diffusion welding is performed on the copper plate treated in step (2) with the nano-sized surface as the welding surface. The welding specification i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com