Brake method of lifting winch/lifting machine for mines and disc-shaped brake

A technology for disc brakes and hoists, applied in the types of brakes, brake components, brake parts, etc., can solve the problems of reducing the service life of the brake shoes, easily soiling the brake disc, and not having a compact structure, so as to save maintenance. Cost, maintenance and replacement of brake shoes are convenient, and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

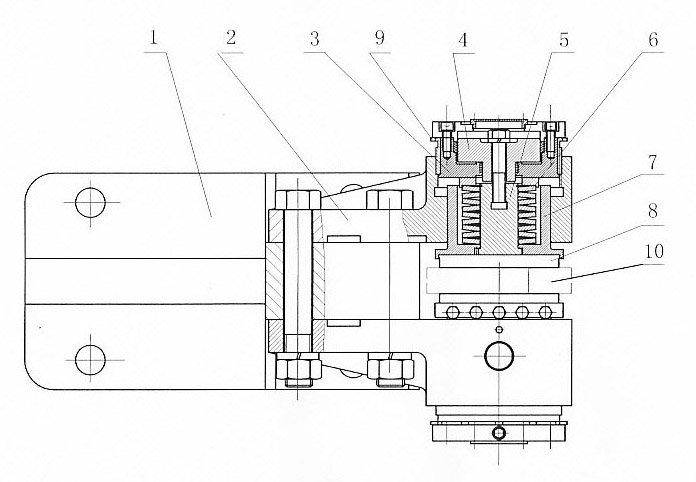

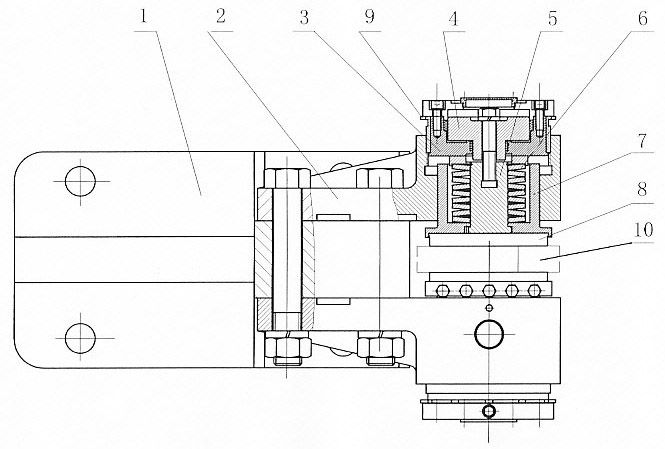

[0015] Such as figure 1 Shown: a mine hoisting winch / hoist disc brake, which is adjusted by a brake leg 1, a support 2, an oil cylinder 3, a piston 4, a guide rod 5, a butterfly spring 6, a brake shoe seat 7 and a brake shoe 8 The screw sleeve 9 is composed of the support 2 on the brake leg 1, the oil cylinder 3 and the brake shoe seat 7 are installed in the inner hole of the support 2, the brake shoe seat 7 can reciprocate along the inner hole of the support 2, the piston 4 and the guide rod 5 is located on the support 2, and the butterfly spring 6 is installed in the brake shoe seat 7 and contacts the outer end surface of the oil cylinder 3. 5mm deep dovetail groove, the adjusting screw sleeve 9 is located between the support 2 and the oil cylinder 3.

[0016] Work process and working principle of the present invention are as follows:

[0017] When the pressure oil enters the oil cylinder 3, the piston 4 pulls up the guide rod 5 to move outward, the guide rod 5 pulls up th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com