Separation method of reaction gas generated in making alkenes from methanol

A separation method and reaction gas technology, applied in the purification/separation of hydrocarbons, chemical instruments and methods, chemical change purification/separation, etc., can solve the comprehensive consideration of MTO reaction gas separation, and achieve the effect of preventing acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

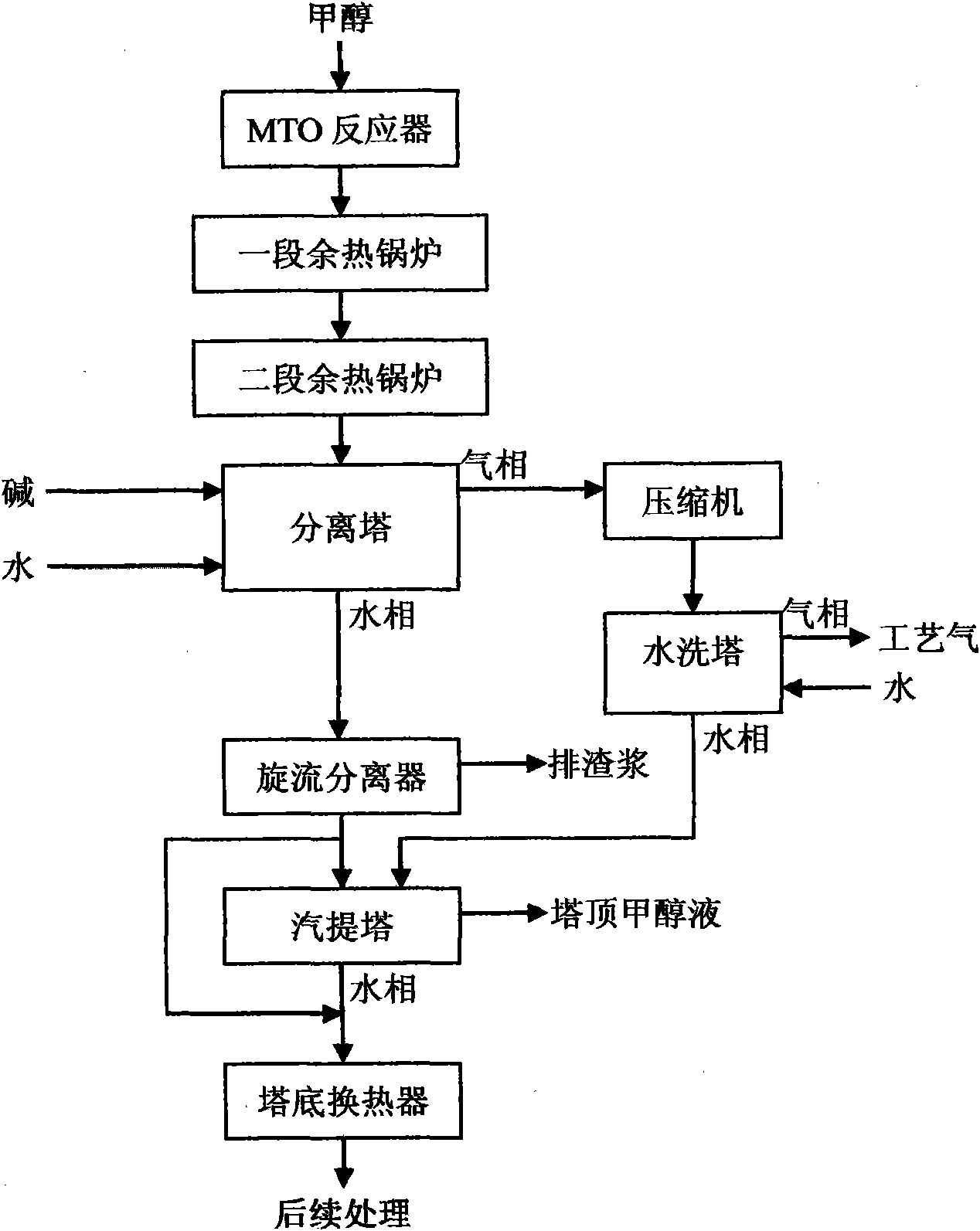

Method used

Image

Examples

Embodiment 1

[0034] For the reaction gas from the MTO reactor, the weight of ethylene and propylene accounts for 31% of the total weight of the reaction gas, the weight of water accounts for 61% of the total weight of the reaction gas, the weight of catalyst powder accounts for 0.2% of the total weight of the reaction gas, and the weight of other organic matter The weight accounts for 8% of the total weight of the reaction gas. When leaving the reactor, the temperature of the MTO reaction gas is 460°C. The reaction gas is cooled in the first stage by indirect heat exchange and medium-pressure steam generation. The temperature of the cooled MTO reaction gas is 210°C; then, The method of indirect heat exchange and low-pressure steam generation is used to cool the MTO reaction gas in the second stage. After the second stage cooling, the temperature of the MTO reaction gas is 110°C.

[0035] The MTO reaction gas with a temperature of 110 ° C is passed into the lower part of the separation towe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com