Synthesis method of hafnium tetraethoxide

A technique for the synthesis of tetraethoxyhafnium, which is applied in the field of synthesis of tetraethoxyhafnium, can solve problems such as troublesome operation, and achieve the effect of reducing toxicity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

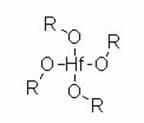

Image

Examples

Embodiment 1

[0019] Synthesis of Tetraethoxyhafnium

[0020] (1) Under a nitrogen atmosphere, add 5.8 g of sodium cut into small pieces and 100 mL of ethanol into a 500 mL three-necked bottle, stir mechanically until the sodium is completely reacted, and then cool to room temperature.

[0021] (2) Add 16 grams of hafnium tetrachloride in batches to the above reaction system, keeping the temperature of the reaction system not higher than 60°C. After adding the hafnium tetrachloride, keep the temperature of the reaction system between 40-65° C., react for 2-8 hours under the condition of mechanical stirring, and then evaporate the remaining ethanol to dryness.

[0022] (3) Then add 150mL of toluene to the solid, stir and filter, the filtrate is concentrated, a white solid is precipitated, and dried in vacuum to obtain a white crystal with a yield of 80-85%wt. The product has passed the identification of H NMR spectrum. 1 H NMR (CDCl 3 , 300 MHz): 4.08-4.28 (m, 8H), 1.19-1.34 (m, 12H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com