Method for smelting vanadium-titanium magnetite in blast furnace

A vanadium-titanium magnetite, blast furnace smelting technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of poor air permeability of material column, high pressure difference, etc., achieve suppression of over-reduction, increase gas utilization rate, and improve technical and economic indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

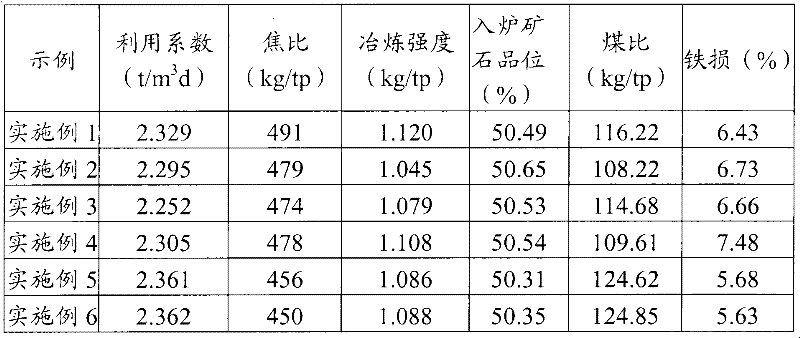

Examples

Embodiment 1

[0022] For the furnace capacity is 2100m 3 The bell-less blast furnace has 28 tuyeres and an area of 0.313m2 2 . The length of the long tuyere arranged on both sides of the iron mouth in the tuyere is 480mm. The blast kinetic energy of the blast furnace is set to 450kJ / s, and the air volume is controlled to be about 5000m 3 / min, the wind speed is controlled within the range of 260m / s. The oxygen enrichment rate of the blast is controlled to be 3.0%. The blast temperature is controlled at 1200°C. The furnace temperature of the blast furnace is about 1450°C. A charging system with an open center and suppressed edge airflow is adopted to control the depth and speed of the blast furnace's material line. The batch weight of the furnace charge is controlled to be about 40t, the depth of the material line is controlled to be about 1.8m, and the material speed is controlled to be 9.5 batches / hour. The slagging and ironing time is controlled to be 80 minutes, and the effectiv...

Embodiment 2

[0024] For the furnace capacity is 1700m 3 The bell-less blast furnace has 24 tuyeres, and the tuyere area is 0.32m 2 . The length of the long tuyere arranged on both sides of the iron mouth in the tuyere is 450mm. The blast kinetic energy of the blast furnace is set to 380kJ / s, and the air volume is controlled to about 4400m 3 / min, the wind speed is controlled within the range of 270m / s. The oxygen enrichment rate of the blast is controlled to be 2.6%. The blast temperature is controlled at 1150°C. The furnace temperature of the blast furnace is about 1500°C. A charging system with an open center and suppressed edge airflow is adopted to control the depth and speed of the blast furnace's material line. The batch weight of the furnace charge is controlled to be about 36.5t, the depth of the material line is controlled to be about 1.9m, and the material speed is controlled to be 10 batches / hour. The slagging and ironing time is controlled at 90 minutes, and the effectiv...

Embodiment 3

[0026] For a furnace capacity of 1000m 3 The bell-less blast furnace has 18 tuyeres with an area of 0.264m2 2 . The length of the long tuyere arranged on both sides of the iron mouth in the tuyere is 450mm. The blast kinetic energy of the blast furnace is set to 260kJ / s, and the air volume is controlled to 3050m 3 / min, the wind speed is controlled within the range of 185m / s. The oxygen enrichment rate of the blast is controlled to be 2.6%. The blast temperature is controlled at 1200°C. The furnace temperature of the blast furnace is about 1480°C. A charging system with an open center and suppressed edge airflow is adopted to control the depth and speed of the blast furnace's material line. The batch weight of the furnace charge is controlled at 22t, the depth of the material line is controlled at 1.8m, and the material speed is controlled at 10.5 batches / hour. The slagging and ironing time is controlled to be 80 minutes, and the effective ironing amount of each slagg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com