Full conversion method and device for producing light aromatic hydrocarbon from catalytic diesel oil

A technology that catalyzes diesel and light aromatics. It is applied in the production of bulk chemicals, hydrocarbon oil treatment products, and aromatics hydrogenation refining. Aromatics and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

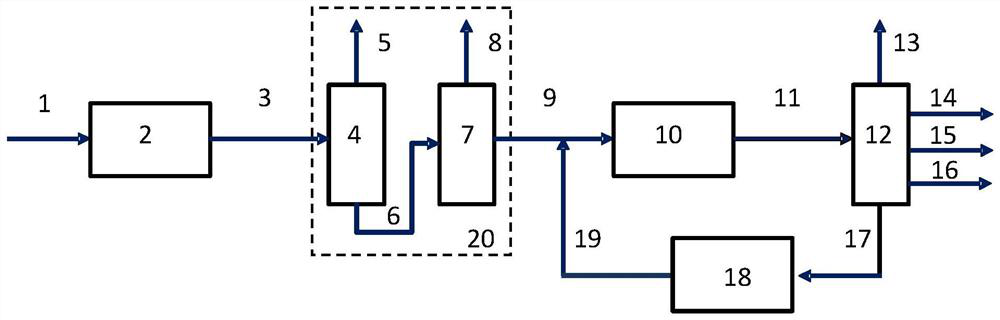

[0139] In this example, the process of preparing light aromatics by catalytic diesel full conversion is as follows figure 1 shown. It includes hydrofining catalytic diesel oil, separating impurities, and selective conversion, and then sending the >210°C heavy tail oil obtained after selective conversion into the post-saturation reaction zone for selective hydrogenation saturation treatment, specifically:

[0140] Wherein the raw material, hydrorefining catalyst, and hydrorefining reaction conditions are the same as Comparative Example 1, and the selective conversion catalyst and reaction conditions are shown in Table 3.

[0141] table 3

[0142]

[0143] Table 3 lists the selective conversion catalyst composition and the reaction conditions employed. Preparation of the selective conversion catalyst: 70wt% zeolite beta (silicon-aluminum molecular ratio SAR=25) and 30wt% alumina are kneaded and extruded to obtain a catalyst carrier. Proper amount of nickel nitrate and ammo...

Embodiment 2

[0154] In this example, the process of preparing light aromatics by catalytic diesel full conversion is as follows figure 1 shown. It includes hydrofining catalytic diesel oil, separating impurities, and selective conversion, and then sending the >210°C heavy tail oil obtained after selective conversion into the post-saturation reaction zone for selective hydrogenation saturation treatment, specifically:

[0155] Wherein the raw material, hydrorefining catalyst, and hydrorefining reaction conditions are the same as Comparative Example 1, and the selective conversion catalyst and reaction conditions are shown in Table 6.

[0156] Table 6

[0157]

[0158] Table 6 lists the selective conversion catalyst composition and the reaction conditions employed.

[0159] Hydrocracking catalyst B3: After fully mixing hydrogen-type mordenite (SAR=45), hydrogen-type zeolite beta (SAR=25), hydrogen-type ZSM-5 (SAR=27) and pseudo-boehmite, kneading and extruding , After drying at 120°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com