Light-controlled thermostatic integrator

An integrator and constant temperature technology, which is applied in the field of light-controlled constant temperature integrated controllers, can solve the problems of low safety, high cost, and large power consumption, and achieve the effects of safe and reliable operation, low manufacturing cost, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

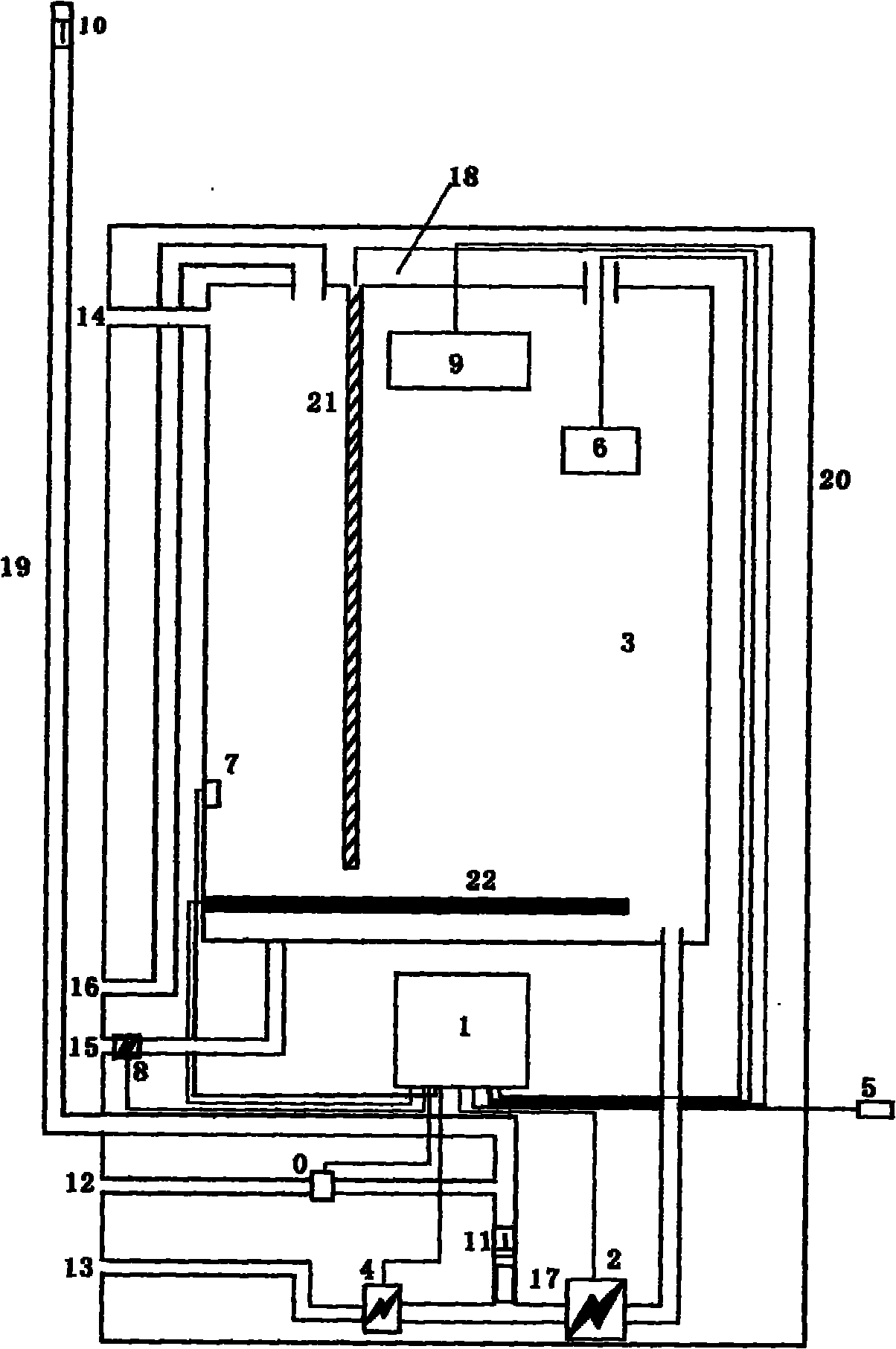

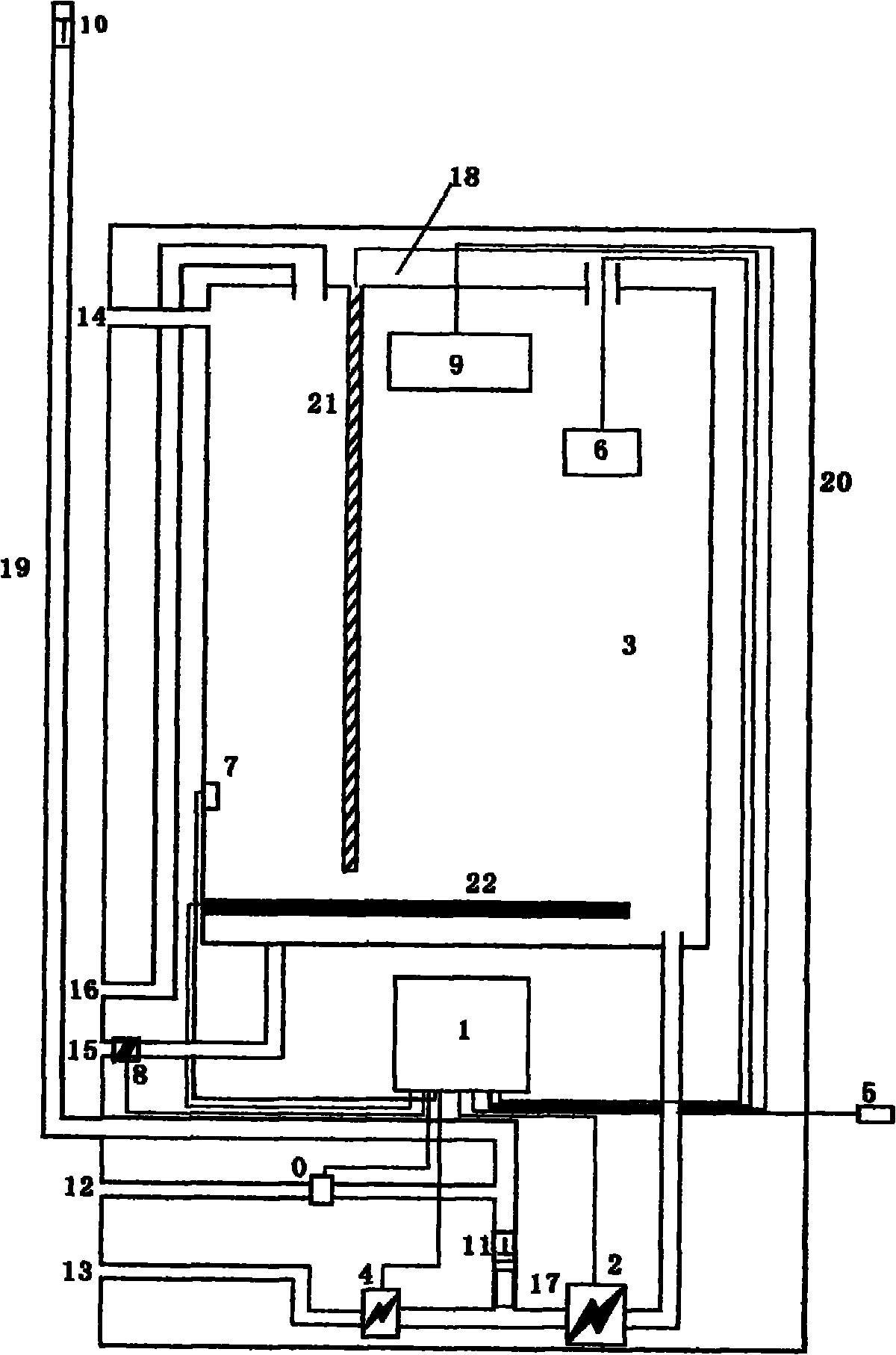

[0023] Specific embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings: figure 1 Shown in: light-controlled constant temperature integrator, which includes an integrator 1, and the corresponding light sensor 5, water level sensor 6, temperature sensor 7, pressure sensor 0, and other corresponding work pieces display control board 9 , two-way circulating pump 2, electric heating rod 21, multiple control valves 4, 8, and accessory inner water tank 3, multiple one-way valves 10, 11, filter valve 17, exhaust port 16, multiple inlet and outlet pipes 12, 13 , 14, 15, automatic pressurization pipeline 19, insulation layer 18, shell box 20 constitute the whole integrator operating system. It detects the external light through the light sensor 5, and then the integrator 1 completes the automatic control and operation of the whole system through programming based on the detection of each sensor.

[0024] In the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com