Liquid crystal display (LCD)

A liquid crystal display and liquid crystal panel technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as difficulty in ensuring flatness, affecting optical effects, and insufficient strength, so as to overcome difficulties in ensuring flatness, realize integration, and overall The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

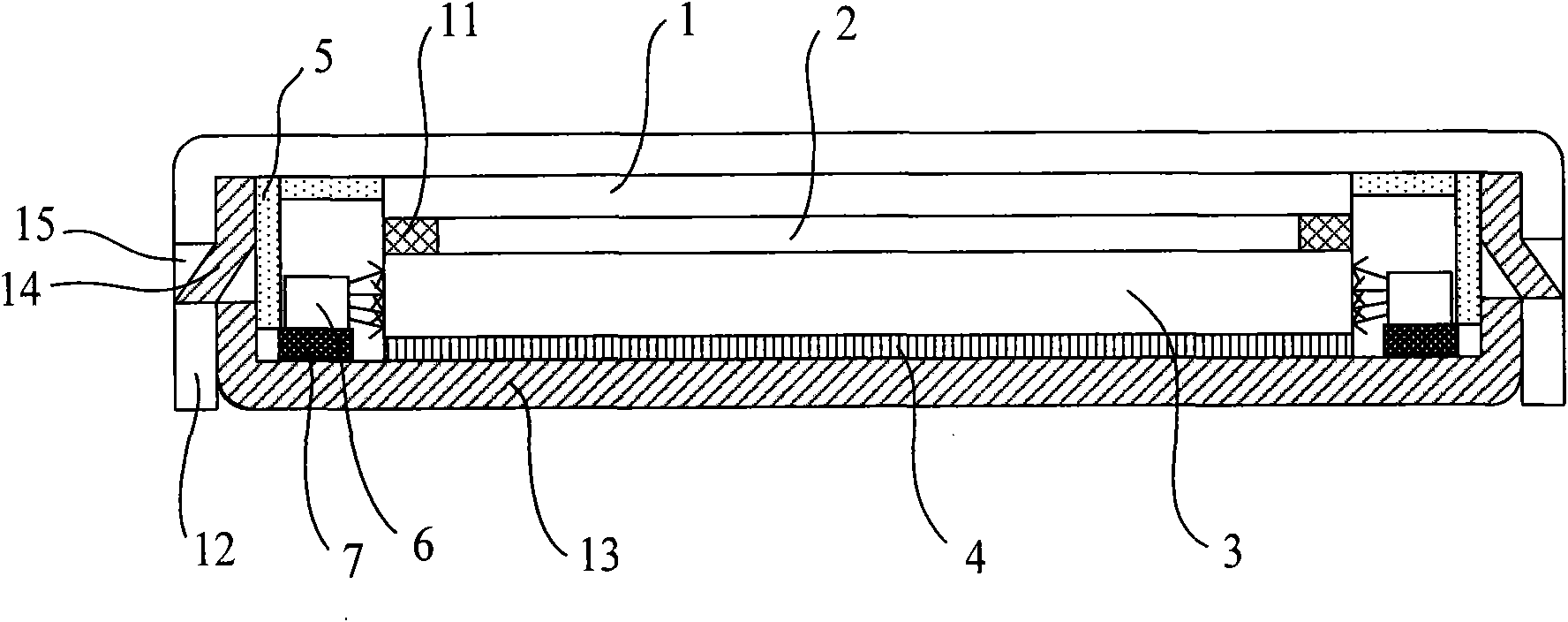

[0040] figure 1 Embodiment 1 of the present invention provides a schematic diagram of a side-view structure of a liquid crystal display when the light source adopts a side-emitting type. The liquid crystal display of this embodiment includes: a liquid crystal panel 1 , an optical film layer 2 , a backlight module, a bottom backplane 13 and an upper cover 12 . Among them, the backlight module at least includes a light guide plate 3, a first reflection sheet 4, a light source 6 and a light source circuit board 7; the optical film layer 2 can be a composite film with a diffusion effect and a light enhancement effect, or at least include a prism sheet and a Diffusion sheets and other membranes on the lower side; the first reflection sheet 4 is located on the upper surface of the bottom back plate 13, the light guide plate 3 is located on the upper surface of the first reflection sheet 4, the optical film layer 2 is located on the upper surface of the light guide plate 3, and the l...

Embodiment 2

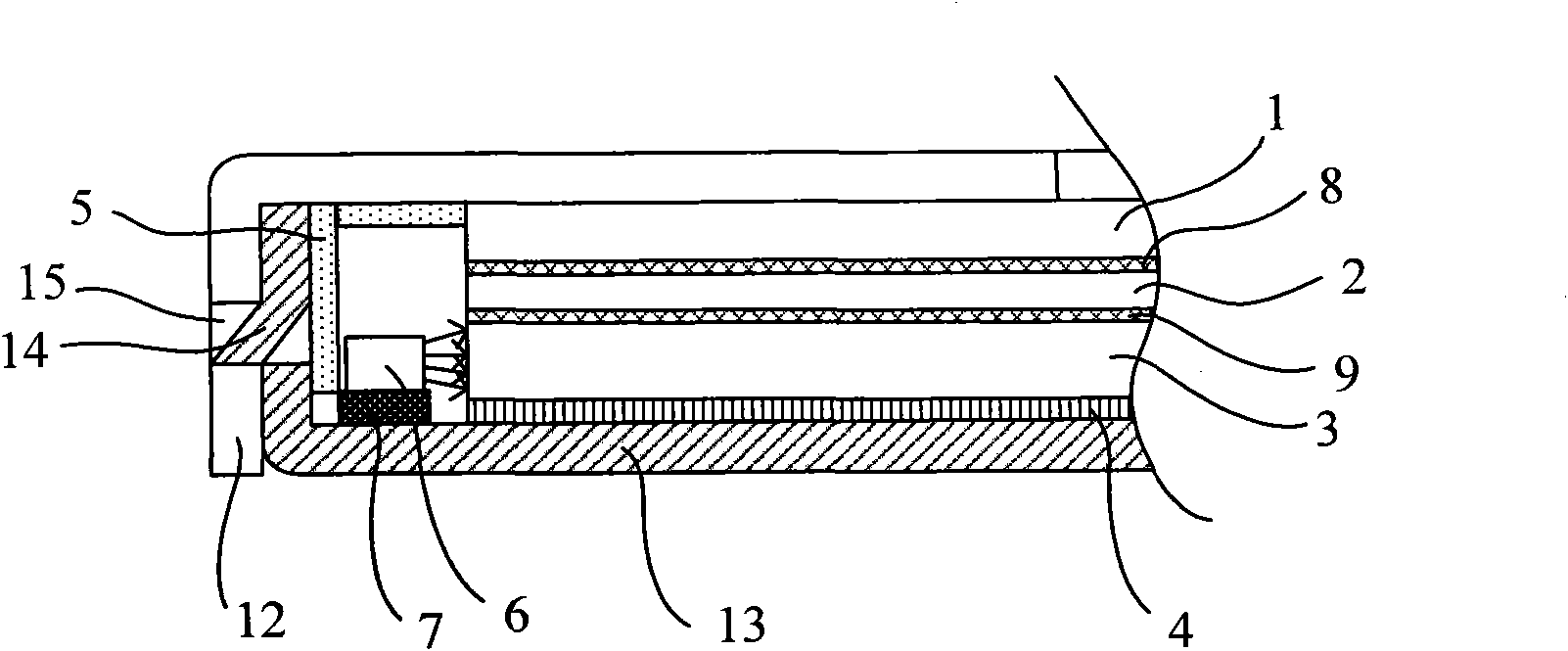

[0046] figure 2 A schematic diagram of a side-view structure of a liquid crystal display when the light source provided by Embodiment 2 of the present invention adopts a side-emitting type. The difference between this embodiment and Embodiment 1 is that: the optical film layer 2 is a layer of composite film; the light guide plate 3 and the composite film are bonded together by the second adhesive layer 9; the composite film and the liquid crystal panel 1, bonded together by the third adhesive layer 8.

[0047] There can be multiple specific bonding methods for the above-mentioned adhesive layer. For example, from the perspective of the coating position of the adhesive layer, it is preferred to:

[0048] The second adhesive layer 9 is evenly coated on the entire contact surface between the light guide plate 3 and the composite film; the third adhesive layer 8 is evenly coated on the entire contact surface between the composite film and the liquid crystal panel 1 superior. T...

Embodiment 3

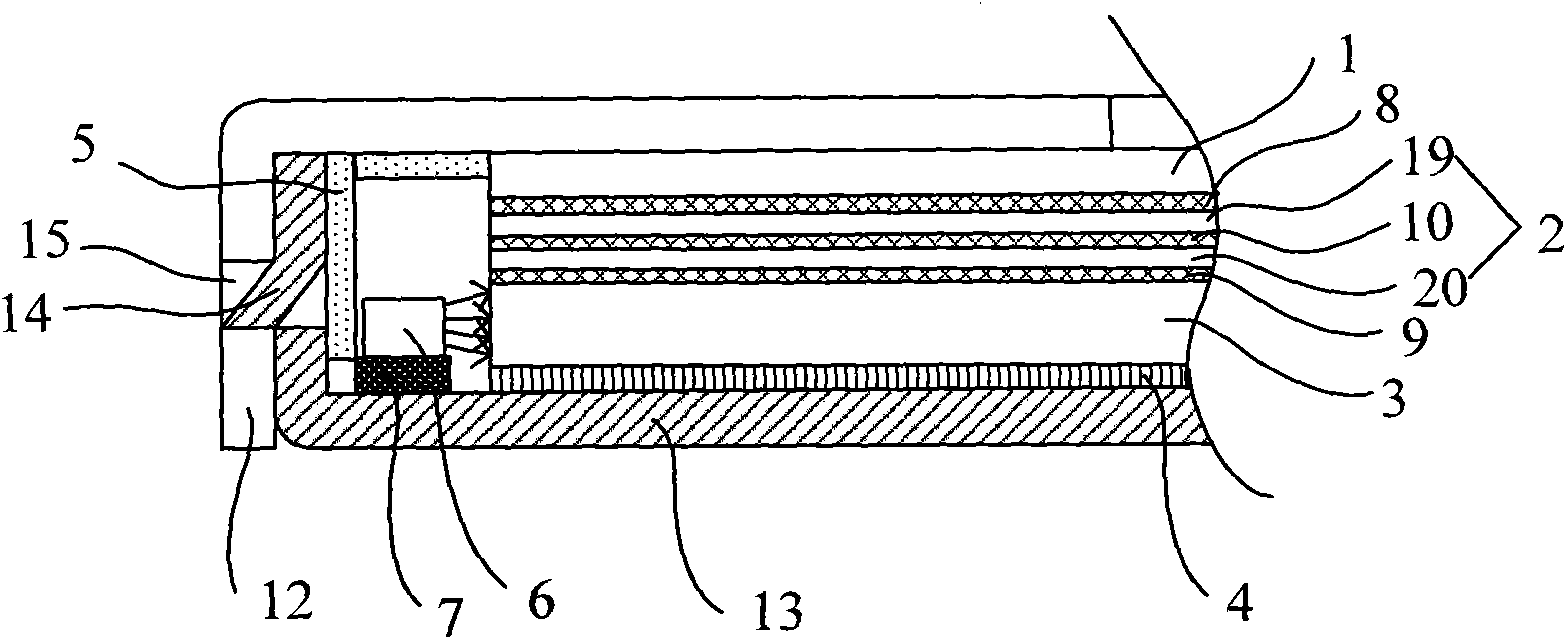

[0052] image 3 A schematic diagram of a side-view structure of a liquid crystal display when the light source provided by Embodiment 3 of the present invention adopts a side-emitting type. The difference between this embodiment and Embodiment 2 is that: the light guide plate 3 and the optical film layer 2 are bonded together through the second adhesive layer 9; the optical film layer 2 and the liquid crystal panel 1 are bonded together through the third adhesive layer 9. The layers 8 are bonded together; the films in the optical film layer 2 are bonded together through the fourth adhesive layer 10 .

[0053] The films of the above-mentioned optical film layer can have various combinations, for example, a combination of a diffusion film, a prism film and a polarizer from the side of the light guide plate to the side of the liquid crystal panel.

[0054] In this embodiment, the optical film layer 2 includes a diffusion sheet 20 located on the upper surface of the light guide p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com