Rust-preventive oil composition

A technology of composition and anti-rust oil, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problem of sufficient anti-rust performance, and achieve the effect of inhibiting rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

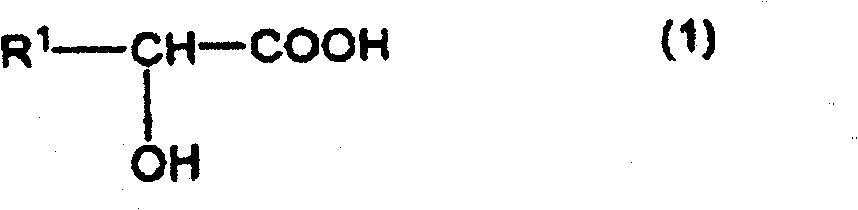

Method used

Image

Examples

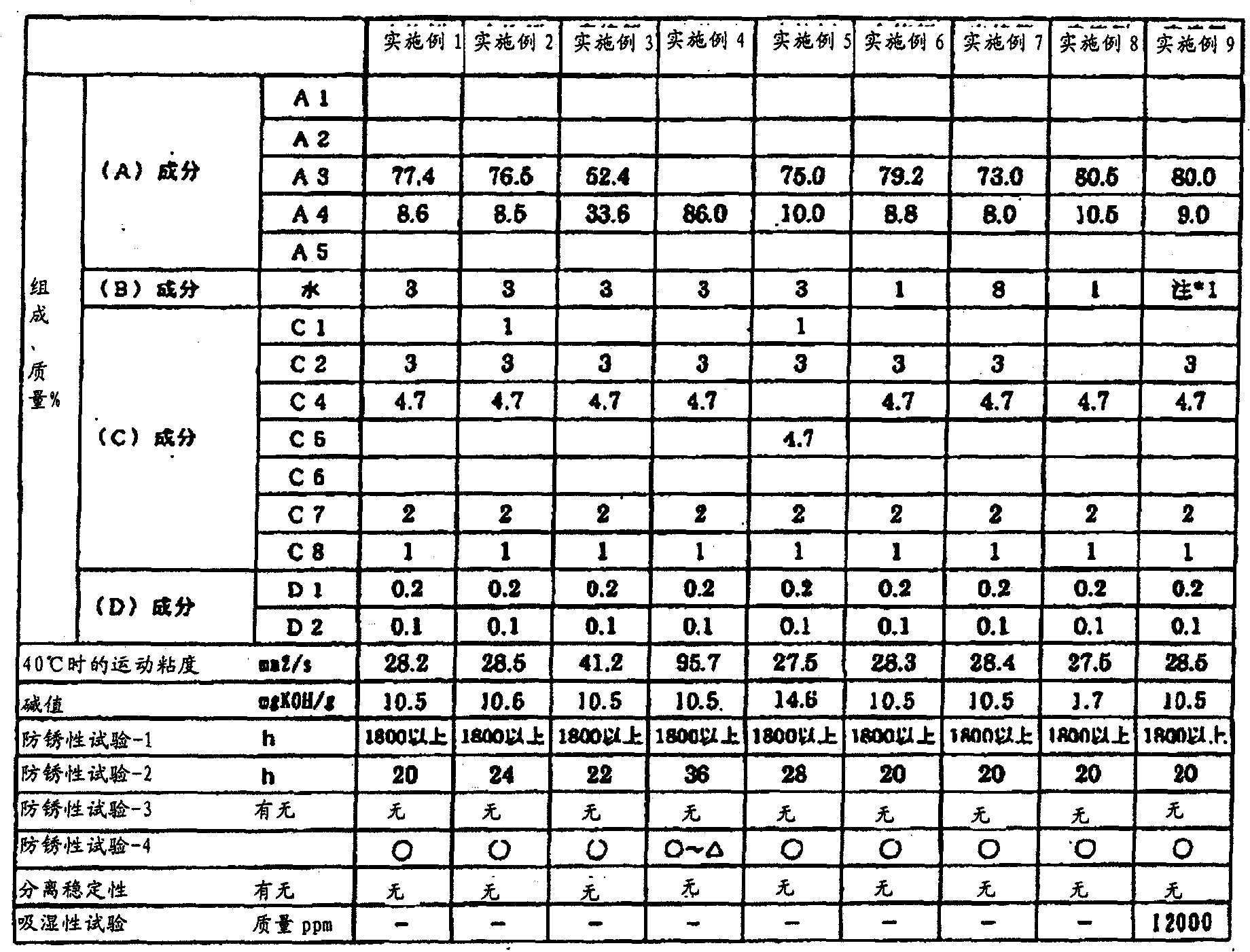

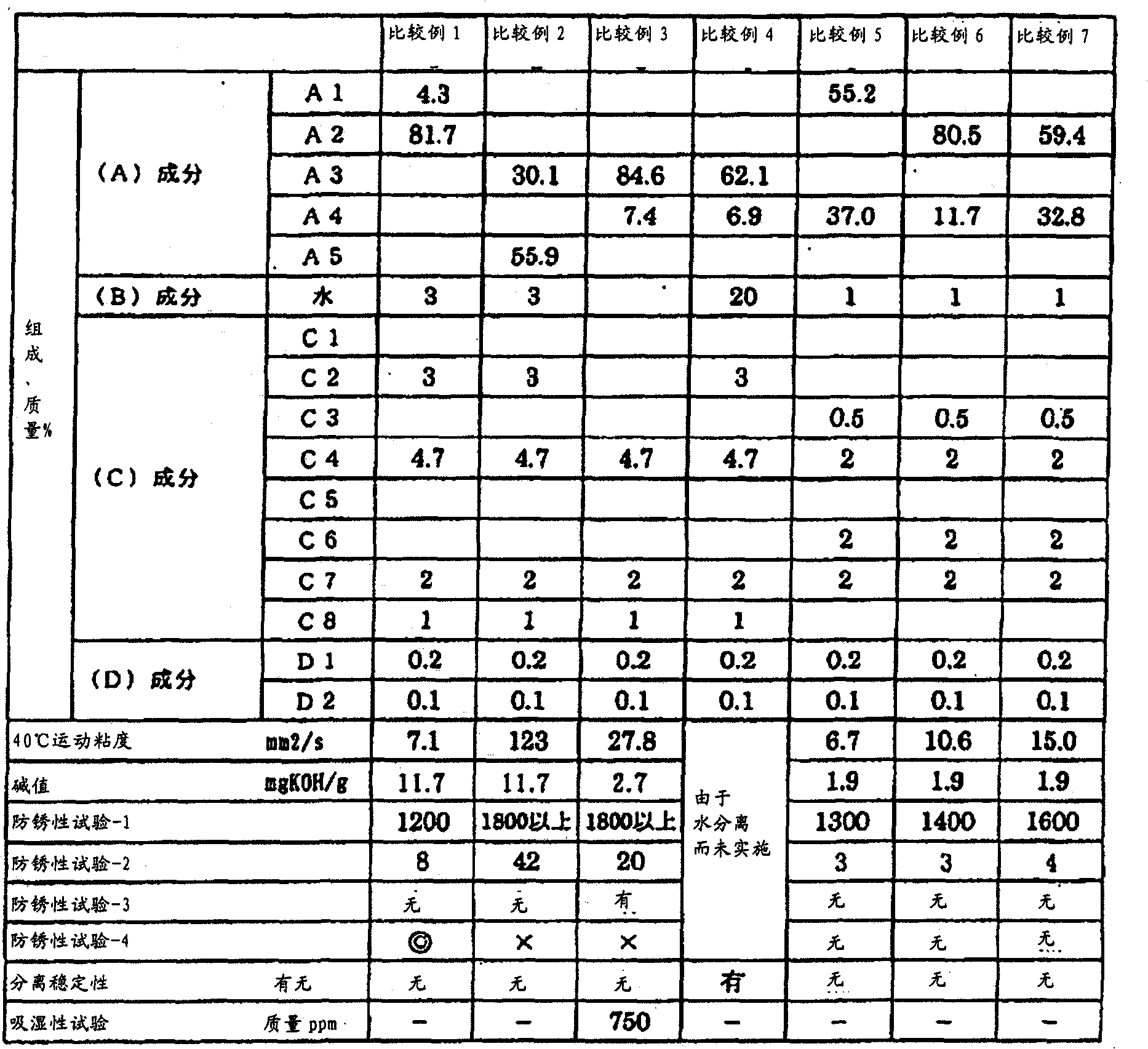

Embodiment 1~9 and comparative example 1~7

[0153] Various antirust oil compositions according to the present invention having compositions shown in Examples 1 to 9 in Table 1 and antirust oil compositions with compositions shown in Comparative Examples 1 to 7 in Table 2 were prepared. The ingredients used in the formulation of each composition are shown below.

[0154] (A) Ingredients

[0155] A1: Kinematic viscosity at 40°C is 1.5mm 2 / s mineral oil

[0156] A2: Kinematic viscosity at 40°C is 6.2mm 2 / s mineral oil

[0157] A3: Kinematic viscosity at 40°C is 22.0mm 2 / s mineral oil

[0158] A4: Kinematic viscosity at 40°C is 93.0mm 2 / s mineral oil

[0159] A 5: Kinematic viscosity at 40°C is 480mm 2 / s mineral oil

[0160] (B) Ingredients

[0161] water (distilled water)

[0162] (C) Ingredients

[0163] Sarcosine compounds

[0164] C1: Oleoyl sarcosine (N-methyl oleoyl acetate)

[0165] Nonionic Surfactant

[0166] C2: Ethylene oxide adduct of cyclohexylamine (EO addition moles: 2)

[0167] C3: Ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com