Controllable coolant pump

A coolant pump, adjustable technology, applied in pump, pump control, pump device, etc., can solve the problems of dynamic performance damage, high processing and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

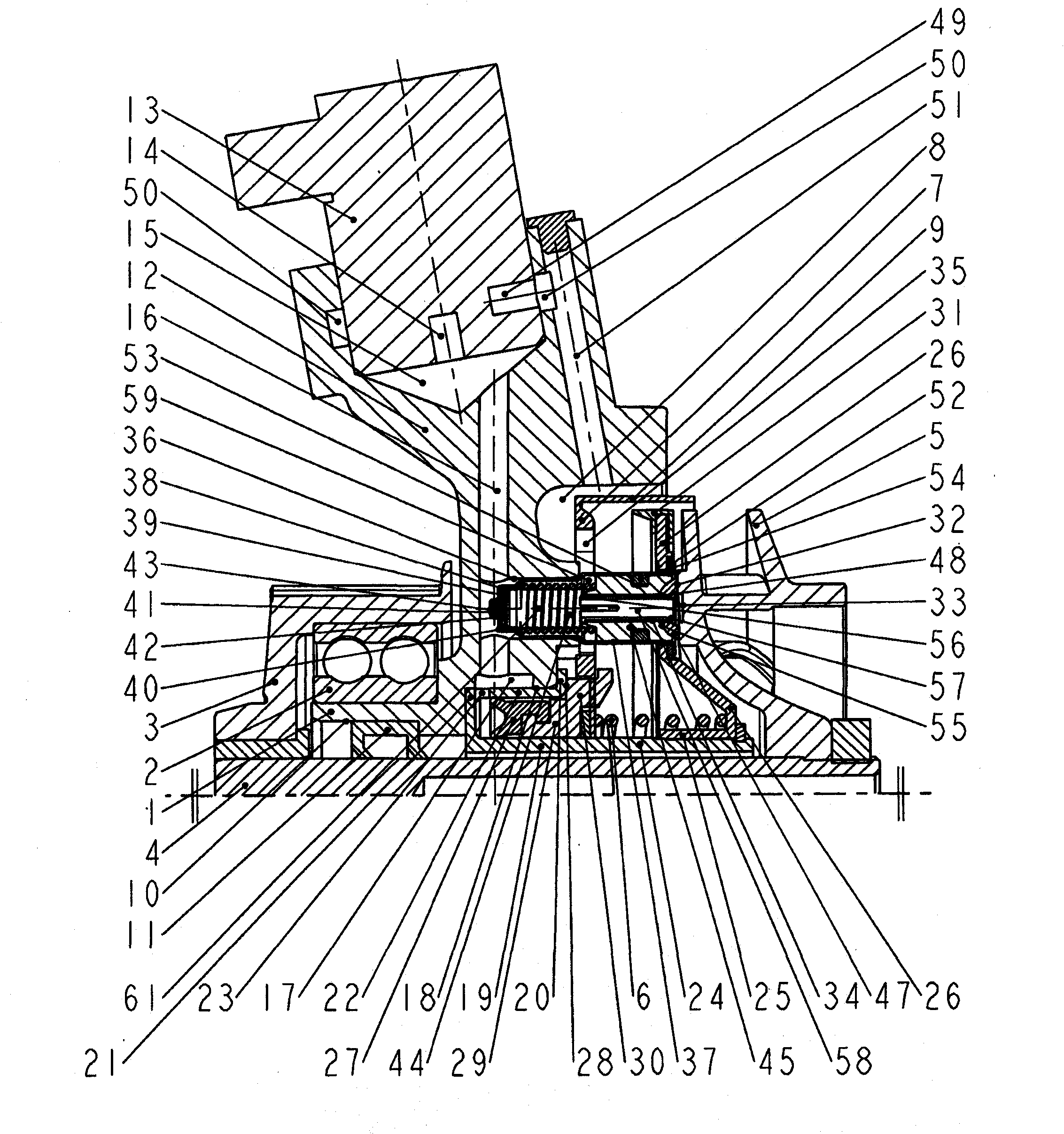

[0036] figure 1 In the form of a side sectional view, the adjustable coolant pump according to the present invention with a slit filter in the first structure is shown, in which the position of the valve core is in its rear end position (that is, in the "open" "In the working position).

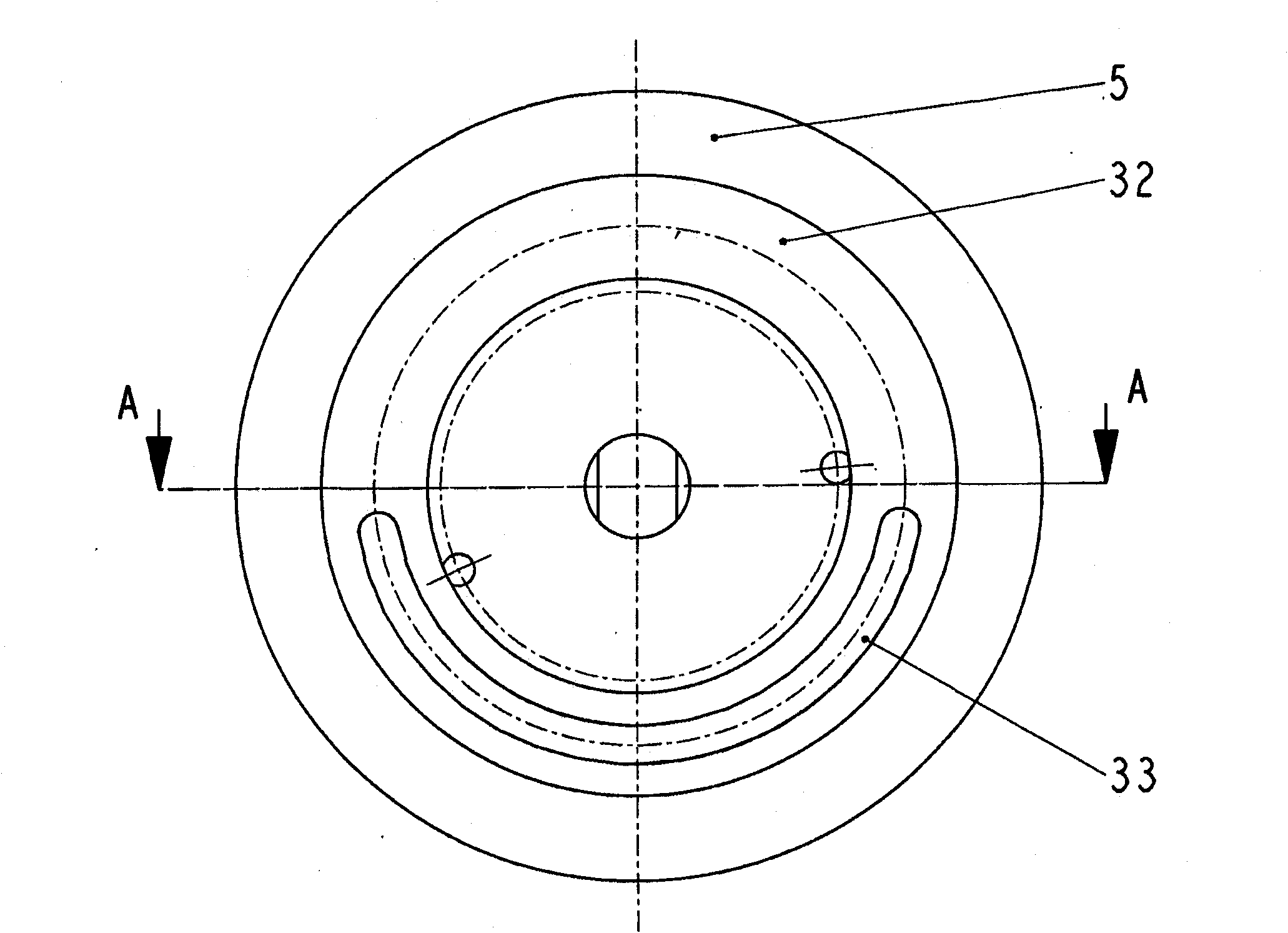

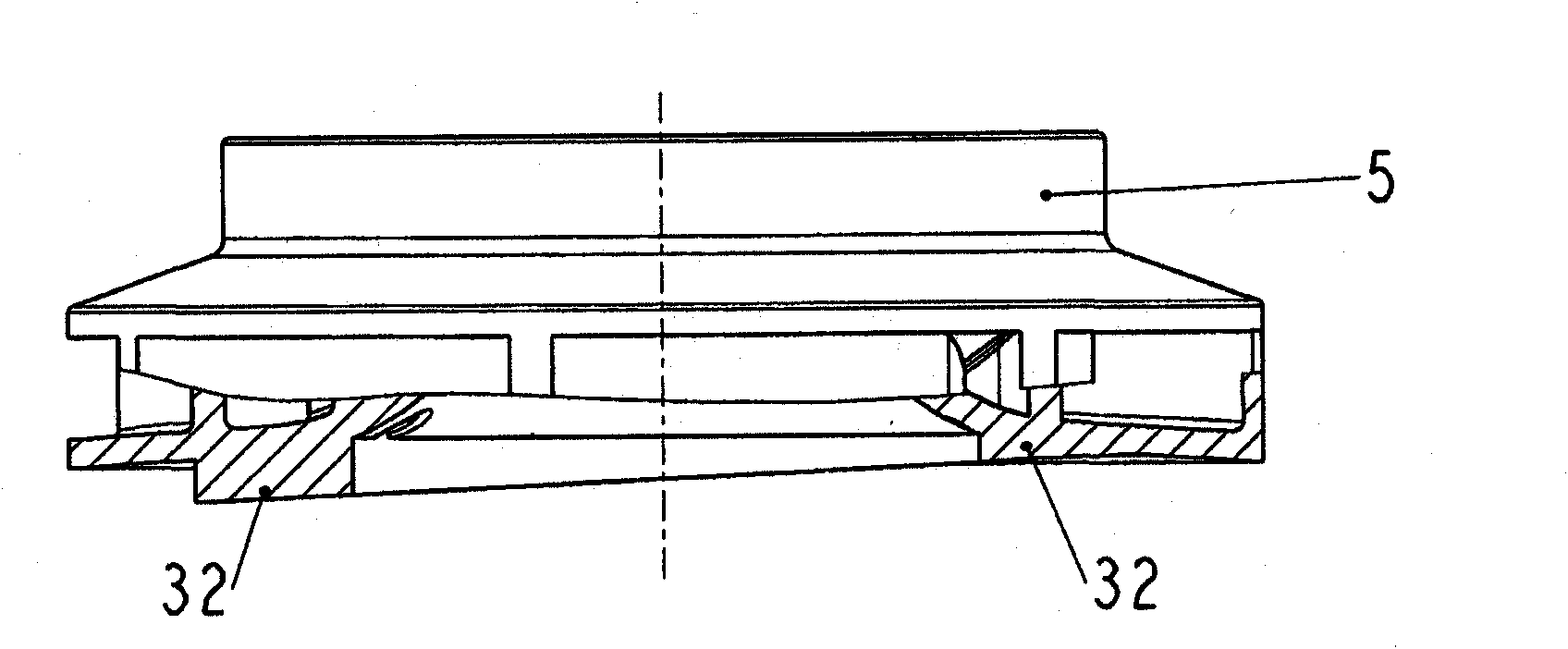

[0037] In this configuration, a pump shaft 4 driven by a pulley 3 with an impeller 5 arranged in a torque-proof manner on the end of the pump shaft 4 on the free-flow side is arranged on a pump housing 1. 2 in.

[0038] In addition, a pressure-operated spool with a rear wall 7 and an outer sleeve 9 that variably covers the outflow region of the impeller 5 and spring-loaded by a return spring 6 is arranged in the pump interior 8.

[0039] In the pump housing 1, a shaft sealing ring 11 is arranged in a sealing seat 10 between the impeller 5 and the pump bearing 2.

[0040] According to the invention, a working housing 12 is arranged on the pump housing 1, and a solenoid valve 13 with an inlet 14 is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com