Double-CPU-based controller for high voltage electrostatic precipitator

A high-voltage electrostatic and dust-removing device technology, applied in the controller field of high-voltage electrostatic dust-removing devices, can solve the problems of reduced system reliability, inability to achieve interconnection of signal transmission, and inability to reliably connect high and low voltage equipment, and achieve reliable performance and humanized display. The effect of high degree of interface and product integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

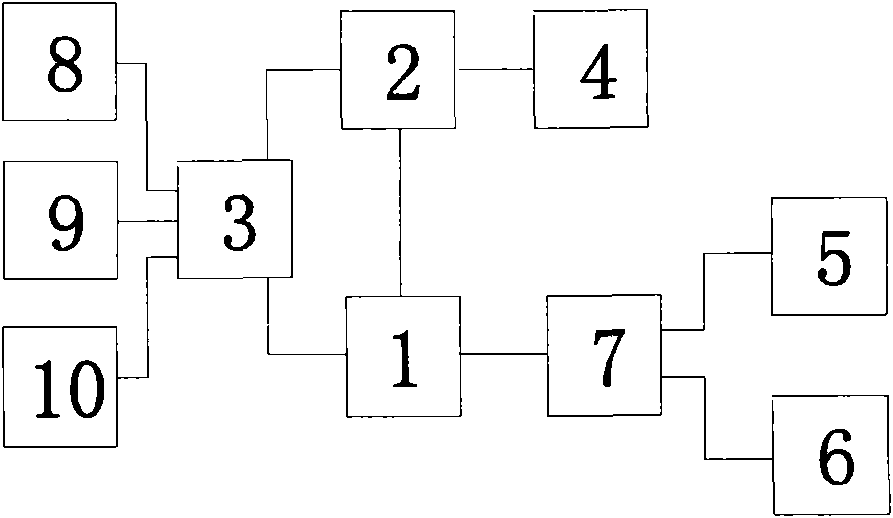

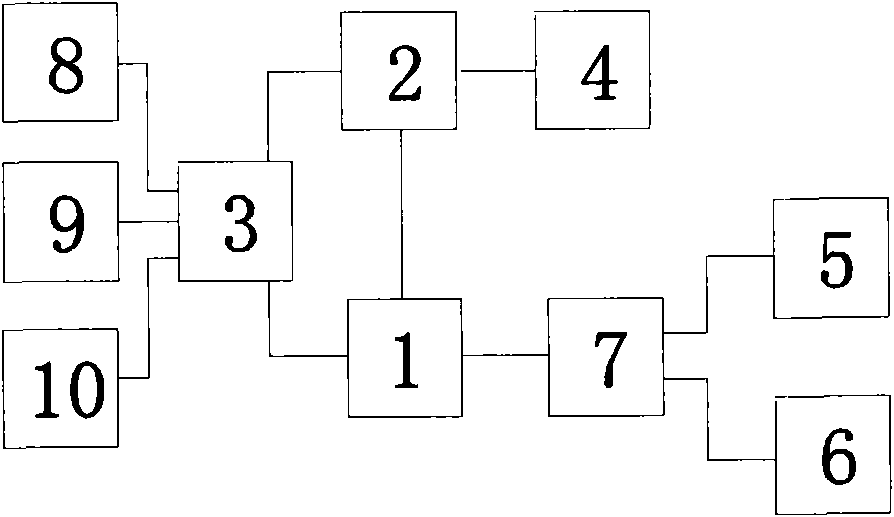

[0020] figure 1 It is a structural schematic diagram of a controller of a high-voltage electrostatic precipitator based on dual CPUs of the present invention, including a main control unit, an I / O unit, an input unit, and an output unit; wherein: the main control unit includes a high-voltage control CPU 1, Low-voltage control CPU 2, drive circuit 3, communication interface circuit 4, thyristor trigger drive circuit 5, analog input circuit 6, photoelectric isolator 7; wherein: the high-voltage control CPU 1 and the low-voltage control CPU 2 are connected in series The high-voltage control CPU 1 and the low-voltage control CPU 2 are connected to the I / O unit, the keyboard input unit and the liquid crystal display output unit through the drive circuit 3; the low-voltage control CPU 2 is triggered by the photoelectric isolator 7 and the thyristor The drive circuit 5 is connected to the analog input circuit 6; the I / O unit is connected to the external input and output interface; th...

Embodiment approach 2

[0025]figure 1 It is a structural schematic diagram of a controller of a high-voltage electrostatic precipitator based on dual CPUs of the present invention, including a main control unit, an I / O unit, an input unit, and an output unit; wherein: the main control unit includes a high-voltage control CPU 1, Low-voltage control CPU 2, drive circuit 3, communication interface circuit 4, thyristor trigger drive circuit 5, analog input circuit 6, photoelectric isolator 7; wherein: the high-voltage control CPU 1 and the low-voltage control CPU 2 are connected in series The high-voltage control CPU 1 and the low-voltage control CPU 2 are connected to the I / O unit, the keyboard input unit and the liquid crystal display output unit through the drive circuit 3; the low-voltage control CPU 2 is triggered by the photoelectric isolator 7 and the thyristor The drive circuit 5 is connected to the analog input circuit 6; the I / O unit is connected to the external input and output interface; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com