Preparation method of multi-ceramic composite coating

A ceramic composite and coating technology, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of poor high temperature oxidation resistance, poor coating performance, unsuitable for application, etc., and achieve high density, The effect of low cost and close combination of phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

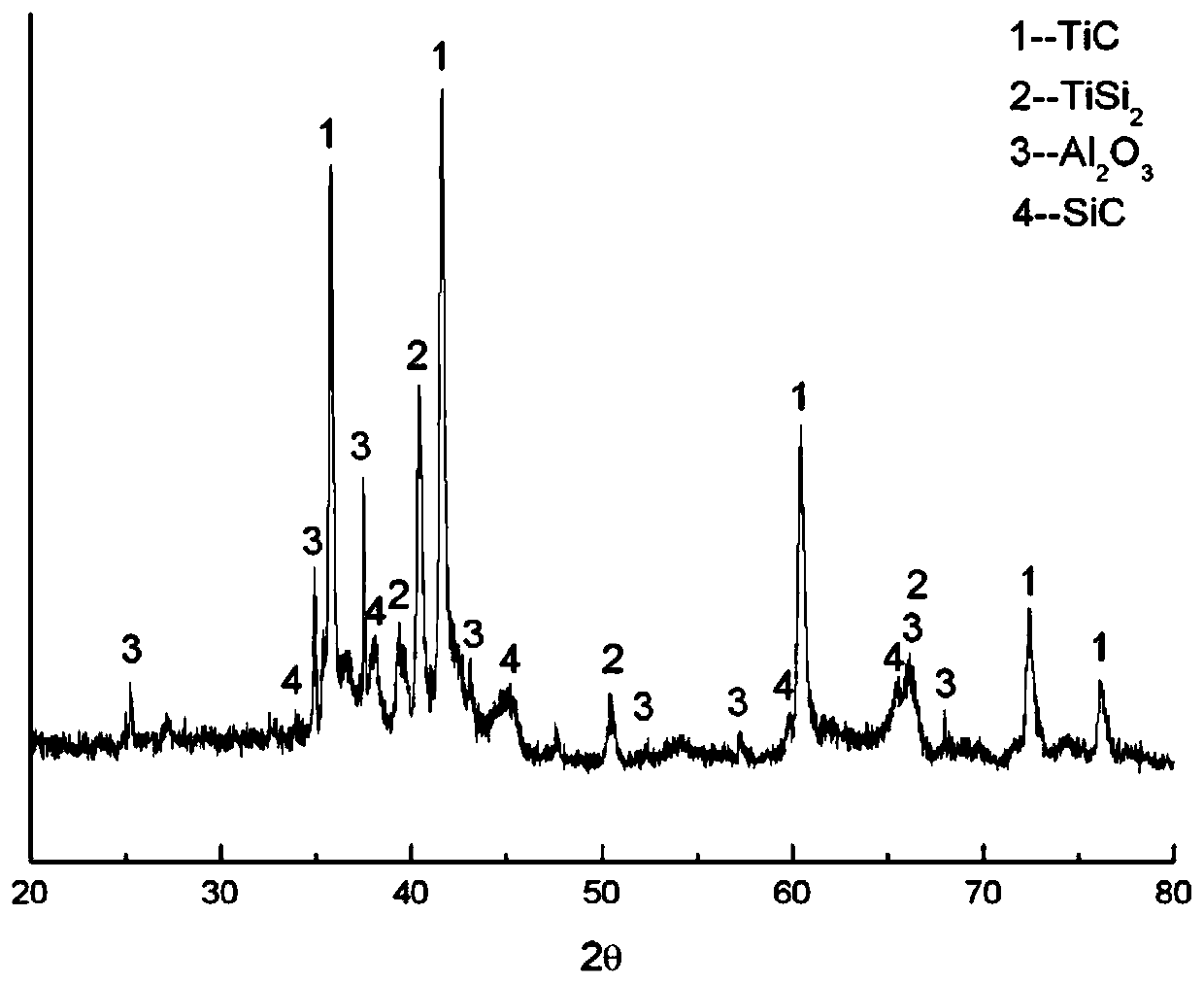

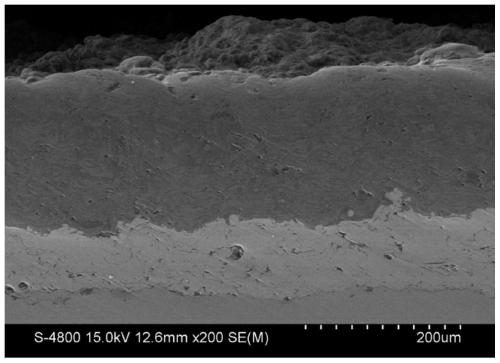

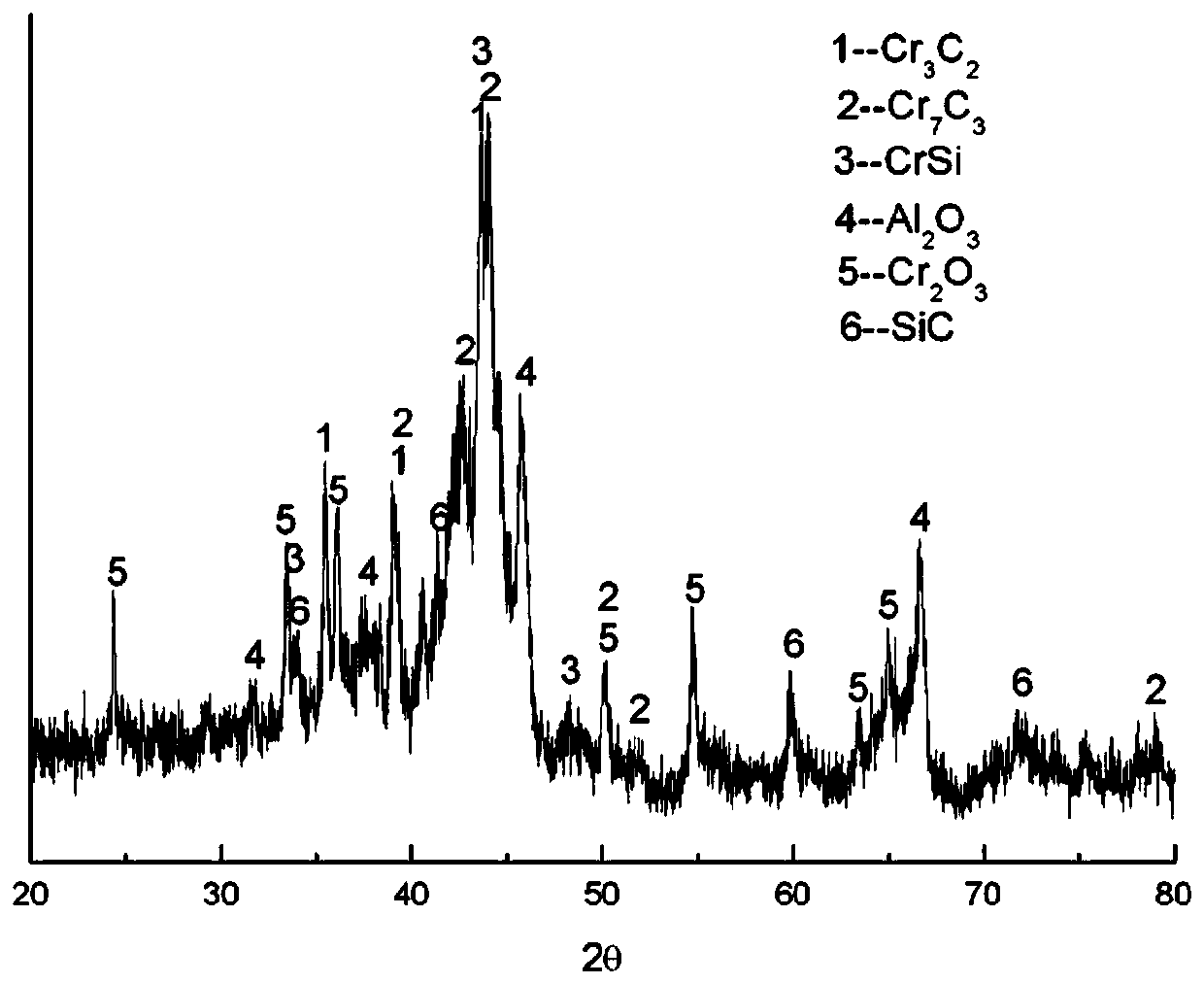

Image

Examples

Embodiment 1

[0048] The first step is to prepare zirconia / silicon carbide / aluminum composite powder for thermal spraying:

[0049] The zirconia powder with a particle size range of 0.001 microns to 10 microns, silicon carbide powder with a particle size range of 0.001 microns to 10 microns, and aluminum powders with a particle size range of 0.1 microns to 10 microns are uniformly mixed into composite powder. Among them, the silicon carbide powder accounts for 5% of the total mass of the above-mentioned zirconia powder, silicon carbide powder and aluminum powder, and the aluminum powder plus zirconia powder accounts for the above-mentioned zirconia powder, silicon carbide powder and aluminum powder. The mass percentage of the total mass of the three raw material powders is 95%, the mass ratio between the zirconia powder and the aluminum powder is 60:40, and then the binder (methyl cellulose, the same as in Example 2-10) is uniformly mixed, The amount of the binder is such that the weight ra...

Embodiment 2

[0055] The first step is to prepare zirconia / silicon carbide / aluminum composite powder for thermal spraying:

[0056] The zirconia powder with a particle size range of 0.001 microns to 10 microns, silicon carbide powder with a particle size range of 0.001 microns to 10 microns, and aluminum powders with a particle size range of 0.1 microns to 10 microns are uniformly mixed into composite powder. Among them, the silicon carbide powder accounts for 10% of the total mass of the above-mentioned zirconia powder, silicon carbide powder and aluminum powder, and the aluminum powder plus zirconia powder accounts for the above-mentioned zirconia powder, silicon carbide powder and aluminum powder. The mass percentage of the total mass of the three raw material powders is 90%, the mass ratio between the zirconia powder and the aluminum powder is 85:15, and then evenly mixed into the binder, the amount of the binder is 100%, and the weight ratio is the above composite powder. : Binder=100:...

Embodiment 3

[0062] The first step is to prepare zirconia / silicon carbide / aluminum composite powder for thermal spraying:

[0063] The zirconia powder with a particle size range of 0.001 microns to 10 microns, silicon carbide powder with a particle size range of 0.001 microns to 10 microns, and aluminum powders with a particle size range of 0.1 microns to 10 microns are uniformly mixed into composite powder. Among them, silicon carbide powder accounts for 30% of the total mass of the above-mentioned zirconia powder, silicon carbide powder and aluminum powder, and aluminum powder plus zirconia powder accounts for the above-mentioned zirconia powder, silicon carbide powder and aluminum powder. The mass percentage of the total mass of the three raw material powders is 70%, and the mass ratio between the zirconia powder and the aluminum powder is 90:10, and then evenly mixed into the binder, the amount of the binder is 70%, and the weight ratio is the above composite powder. : Binder = 100:2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com