Process for preparing flame retardant grade magnesium hydroxide by ammonia method

A magnesium hydroxide, flame retardant grade technology, applied in the direction of magnesium hydroxide, etc., can solve problems such as difficulty in filter cake filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

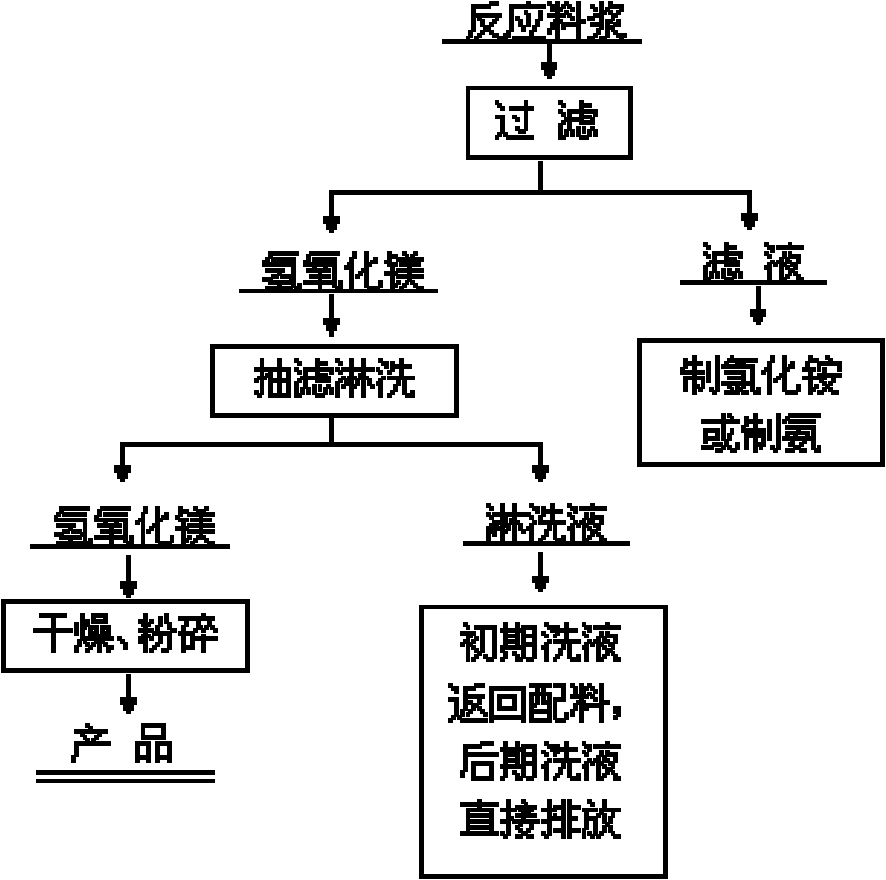

Method used

Image

Examples

Embodiment 1

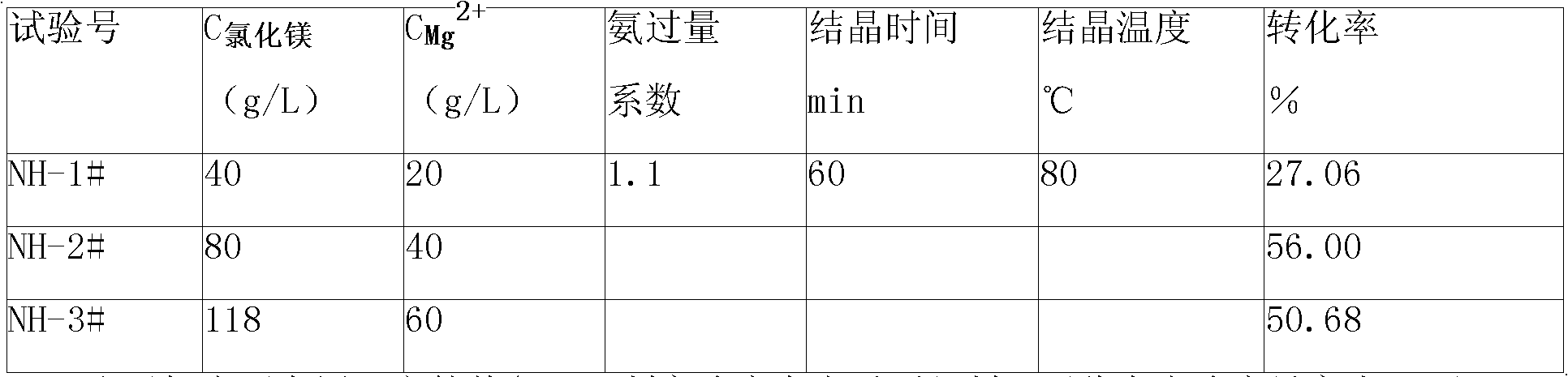

[0093] Embodiment 1 of the present invention: adding water to dissolve the by-product magnesium chloride in the titanium smelting process into Mg 2+ A solution with a concentration of 40g / L is added to the reactor together with ammonia water, the excess coefficient of ammonia is 2.5, and pure magnesium hydroxide with a reaction volume of 20% is added as a seed crystal, reacted at 40°C for 60 minutes, and the reaction slurry is filtered. And use continuous vacuum suction to filter and rinse, then dry and pulverize to obtain the fibrous magnesium hydroxide crystal product. The product has been tested to meet the flame-retardant magnesium hydroxide HG / T3607-2000 Class I standard.

Embodiment 2

[0094] Embodiment 2 of the present invention: Mg 2+ Add purified brine and ammonia water with a concentration of 40g / L into the reaction kettle, the ammonia excess coefficient is 2.5, and add pure magnesium hydroxide with a reaction volume of 20% as a seed crystal, react at 40°C for 60 minutes, filter and wash the reaction slurry , and then dried and crushed to obtain fibrous magnesium hydroxide crystal products. The product has been tested to meet the flame-retardant magnesium hydroxide HG / T3607-2000 Class I standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com