Complex-space curved-surface dot-motion induction heating hardening device and method

A technology of induction heating and quenching device, which is applied in the direction of quenching device, heat treatment equipment, heat treatment process control, etc., to achieve the effects of high degree of generalization, easy automation, and low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with specific embodiments and accompanying drawings, but the content of the present invention is not limited to the following embodiments.

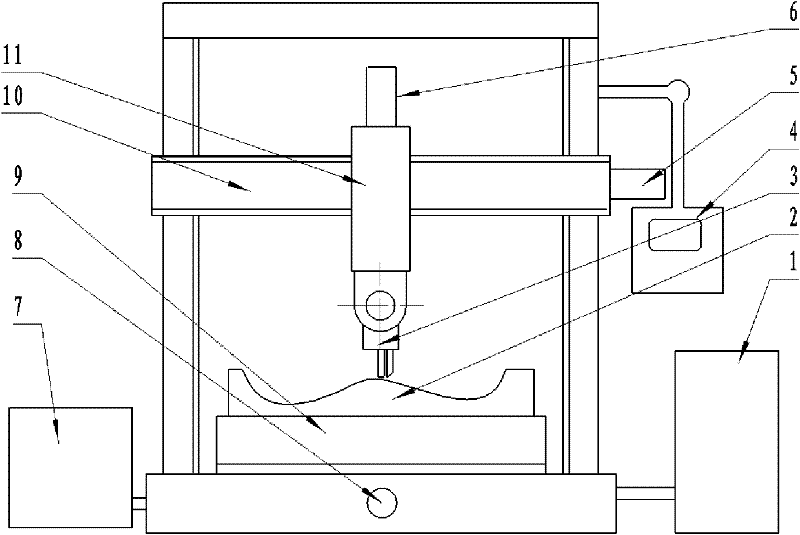

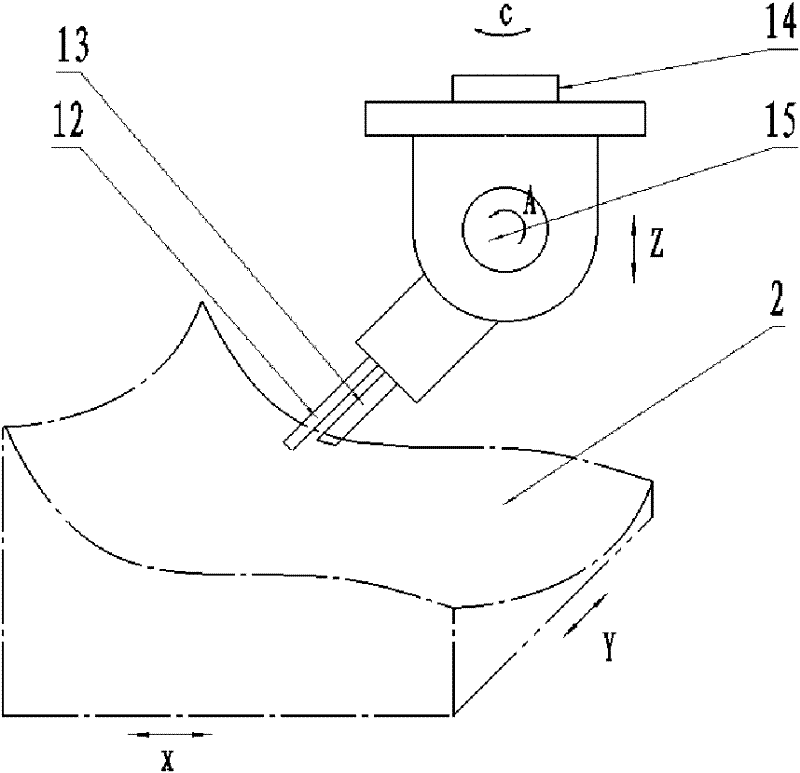

[0039] The complex space curved surface quenching device provided by the present invention has a structure such as figure 1 As shown: it is mainly composed of a numerical control system 4 installed on the frame, a five-axis servo mechanism, an induction heater 12 driven by the five-axis servo mechanism, and a coolant nozzle 13, wherein: the induction heater 12 and the coolant nozzle 13 Three-dimensional continuous movement along the complex space surface of part 2. The induction current provided by the induction power supply 1 is passed into the induction heater 12, and after the surface of the part 2 is heated to the austenite transformation temperature, the cooling medium is sprayed from the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com