Method for preparing highly (100) oriented BiFeO3 films on Si substrate

A high-orientation, substrate technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of poor film grain density, small substrate stress constraints, and large lattice mismatch and other problems, to achieve the effect of dense arrangement, easy adjustment of process parameters, and improvement of magnetoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a) Pretreatment of the Si(100) substrate: the substrate is thoroughly cleaned in an ultrasonic cleaner with toluene, acetone, and ethanol in sequence, then rinsed with deionized water, and soaked in ethanol for later use;

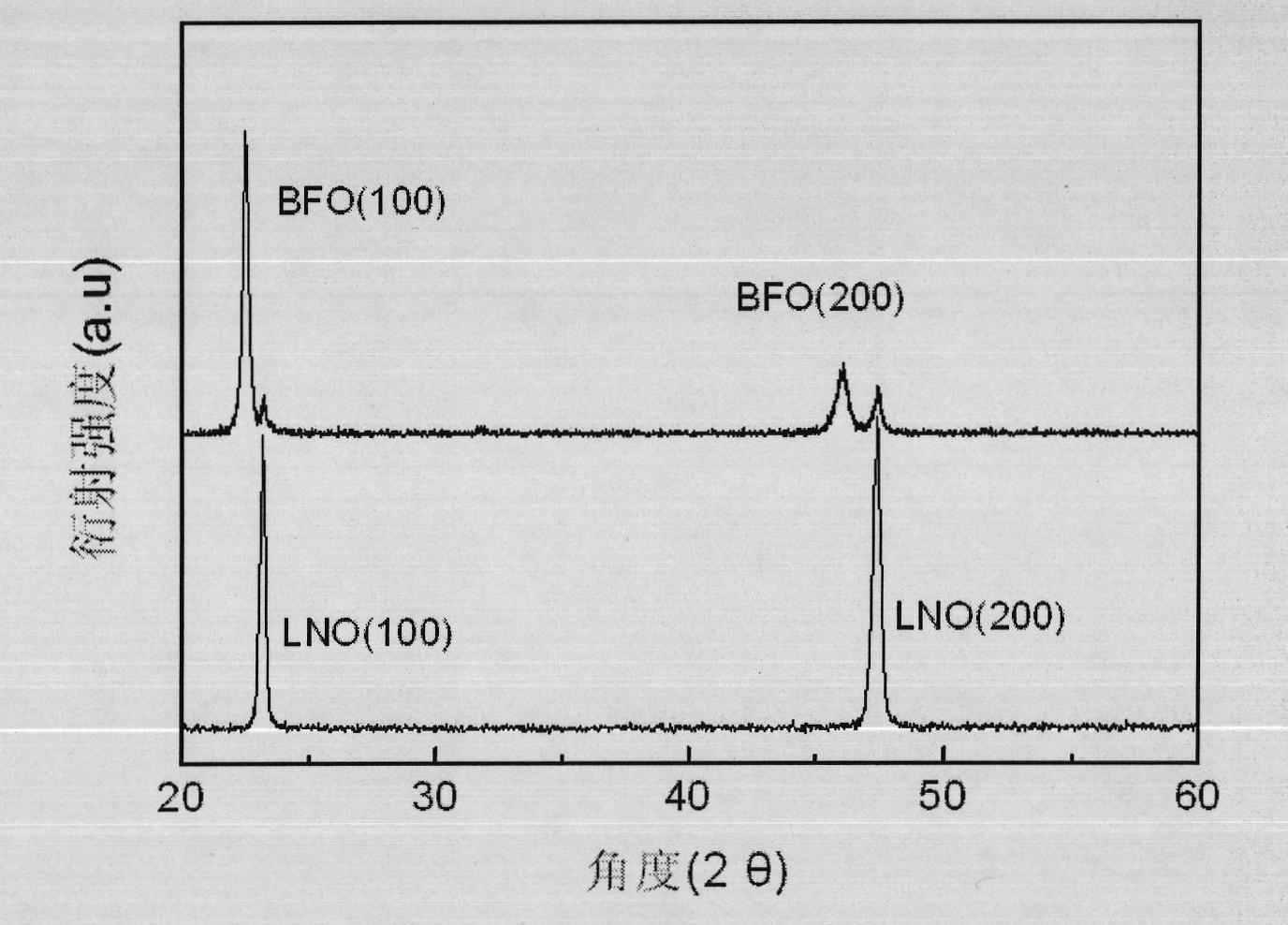

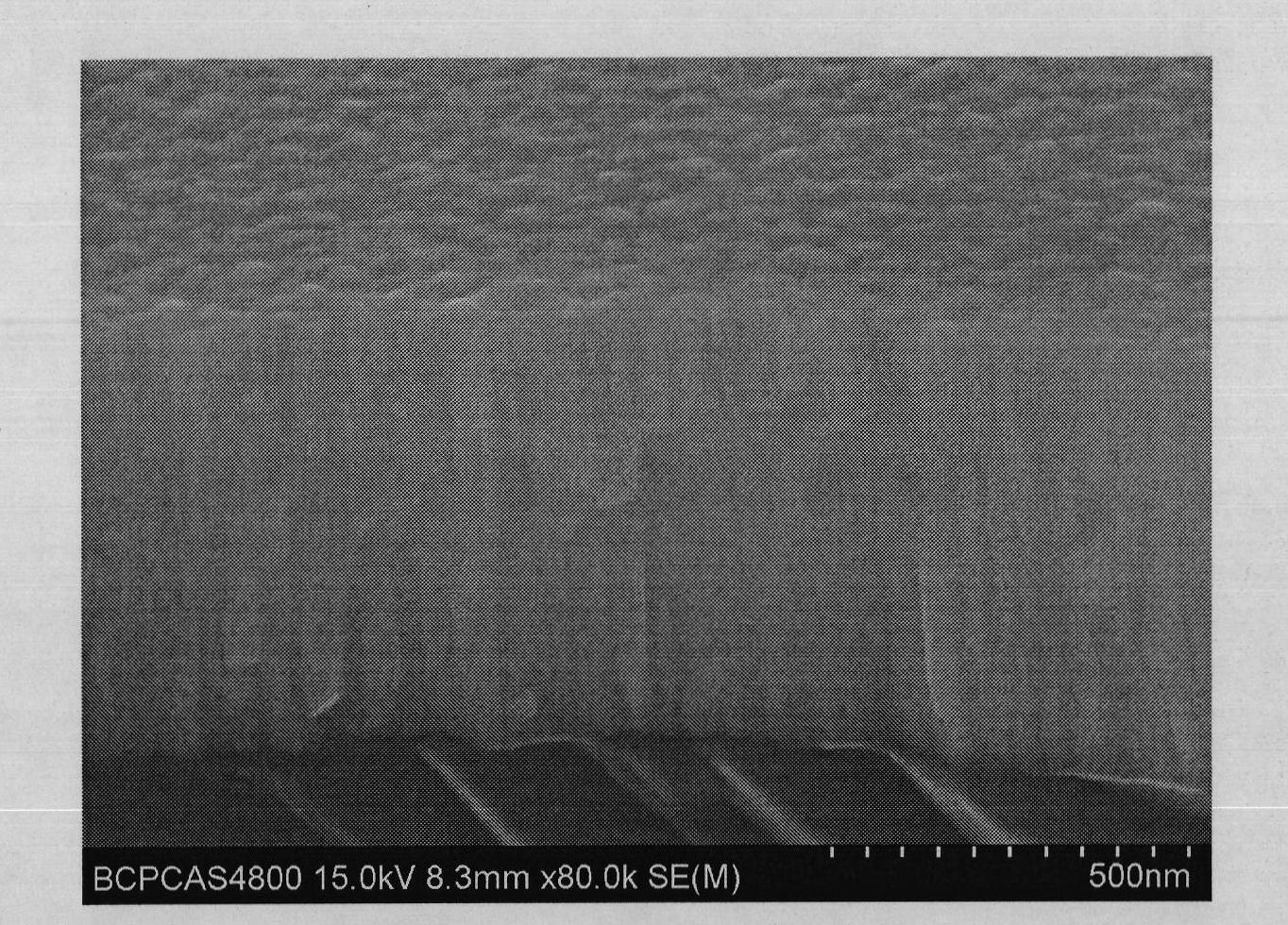

[0027] b) Using the pulsed laser deposition method, using self-made LaNiO 3Target material, on the above substrate, using pulsed laser deposition method, on the Si(100) substrate, the substrate temperature is 750°C, the working oxygen pressure is 5Pa, the laser energy is 400 mJ / pulse, and the pulse frequency is 5Hz. Target base distance 50mm, deposit LaNiO 3 film. The XRD pattern of the obtained film is as follows figure 1 As shown, the film exhibits a high (100) orientation. Film morphology as figure 2 As shown, the thickness of the film is 400nm, the particle size is about 50nm, and the columnar grains are arranged densely and uniformly.

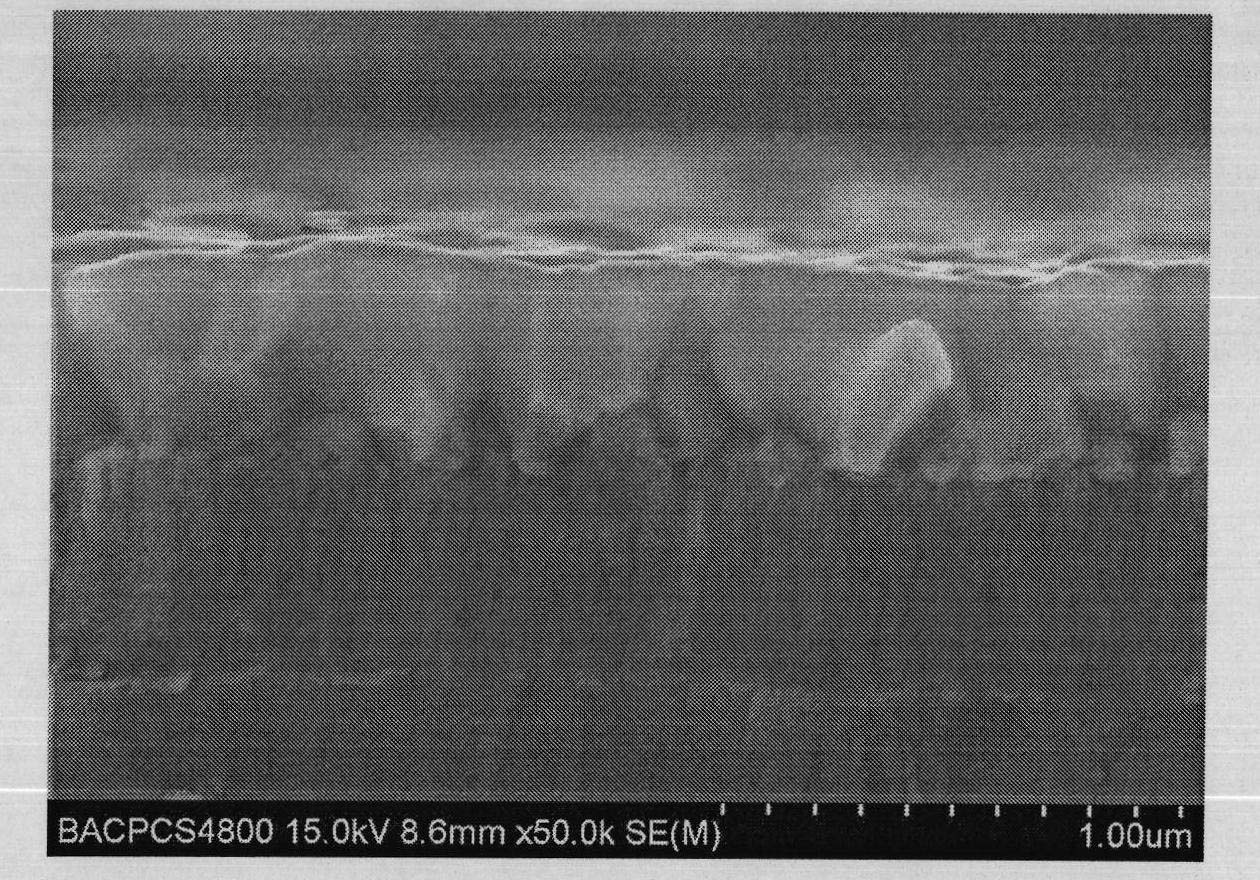

[0028] c) Using the pulsed laser deposition method, using self-made BiFeO 3 Target material, in LaNiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com