Light well point drainage construction technology

A construction technology, light well point technology, applied in infrastructure engineering, construction, etc., can solve the problems of large influence range of precipitation, unsteady control, no drop, etc., to reduce the difficulty and cost of hole forming, improve the progress of hole forming, Small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

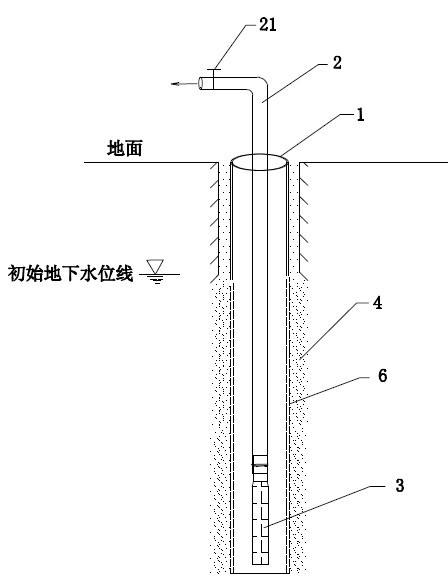

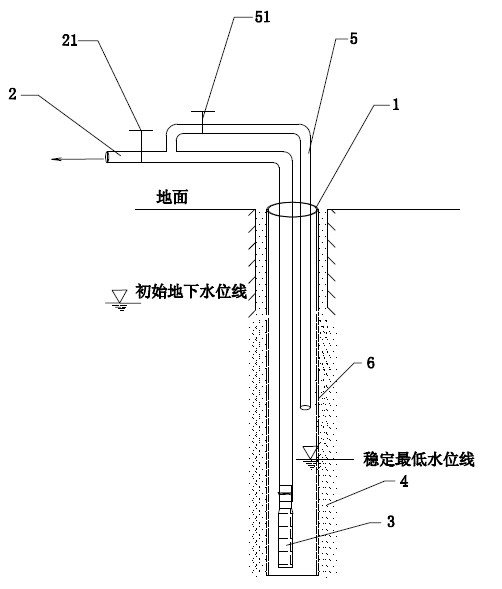

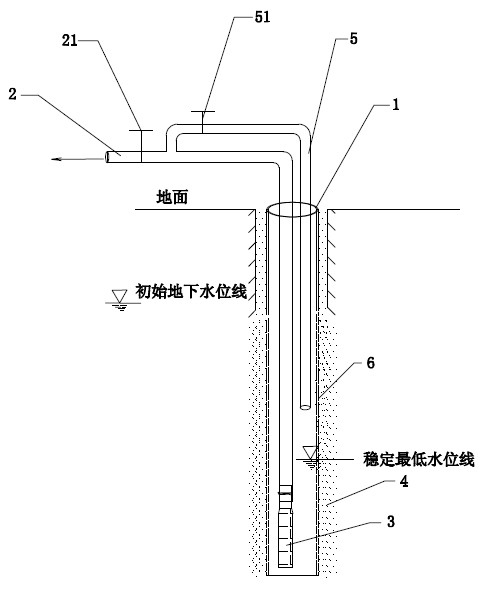

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

[0038] Huizhou Xunliao Coastal Highway Project is located on the coast of Daya Bay in Xunliao Town, Huidong County, Guangdong Province. It is a section of X210 Provincial Highway and is a key project for the development of Xunliao Coastal Resort and Leisure Area.

[0039] The municipal drainage culvert of this project is arranged longitudinally on the left side of the road, and the excavation depth of the foundation pit is about 5-6m. The foundation surface is located in the silt, medium sand and gravel sand layers deposited by the Quaternary marine-terrestrial interaction facies. The buried water level is relatively shallow (only 1.2m), with good water-rich properties and high permeability coefficient. The distance between the foundation pit and the water surface boundary of the sea is 100-150m; engineer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com