Automobile-used muffler

A technology for mufflers and vehicles, which is applied in the direction of mufflers, machines/engines, engine components, etc. It can solve the problems of reduced engine output power, exhaust gas cannot be discharged smoothly, and exhaust muffler effect is poor, so as to reduce exhaust noise, Effect of reducing soot and toxic gas and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

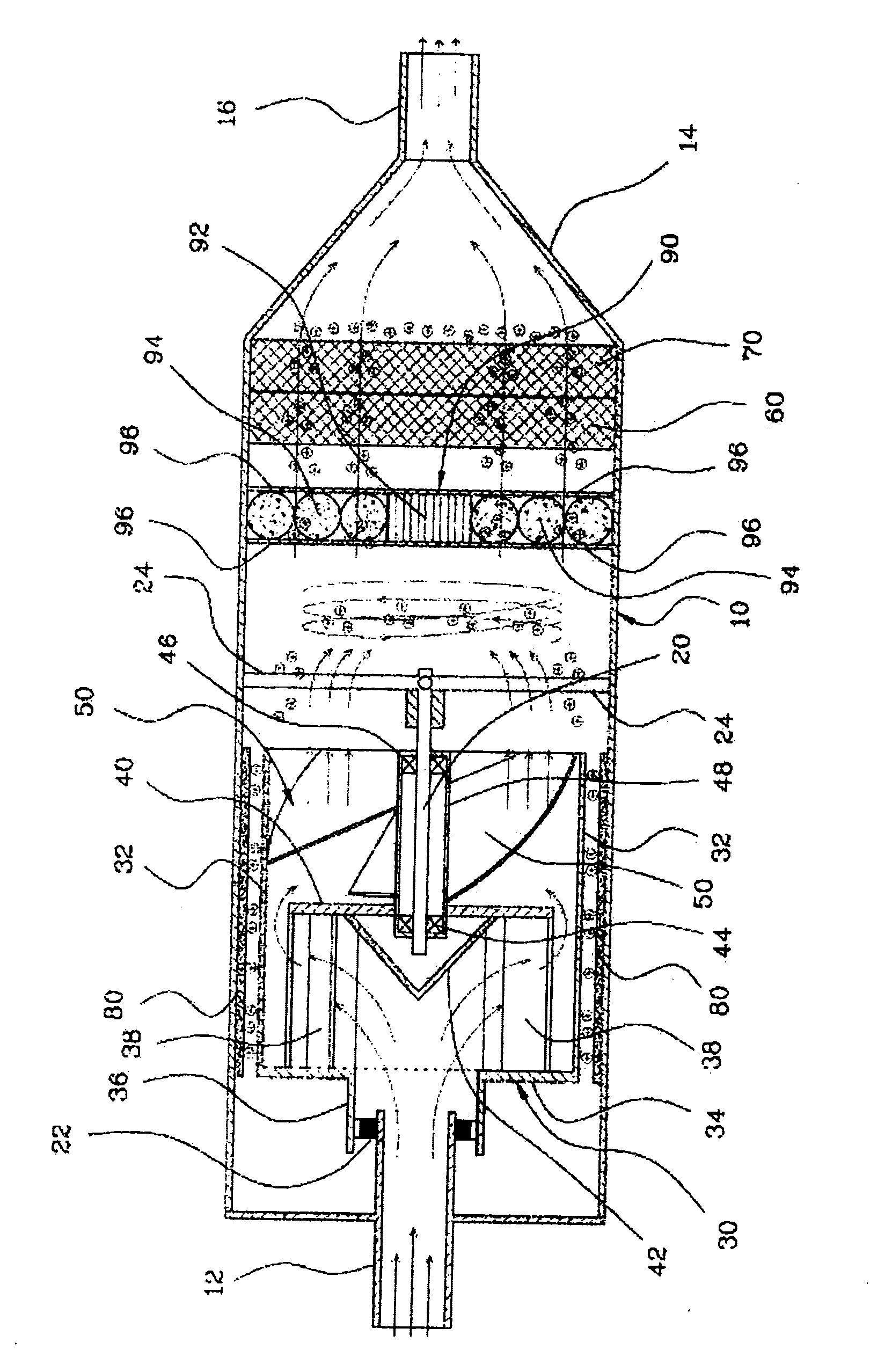

[0039] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

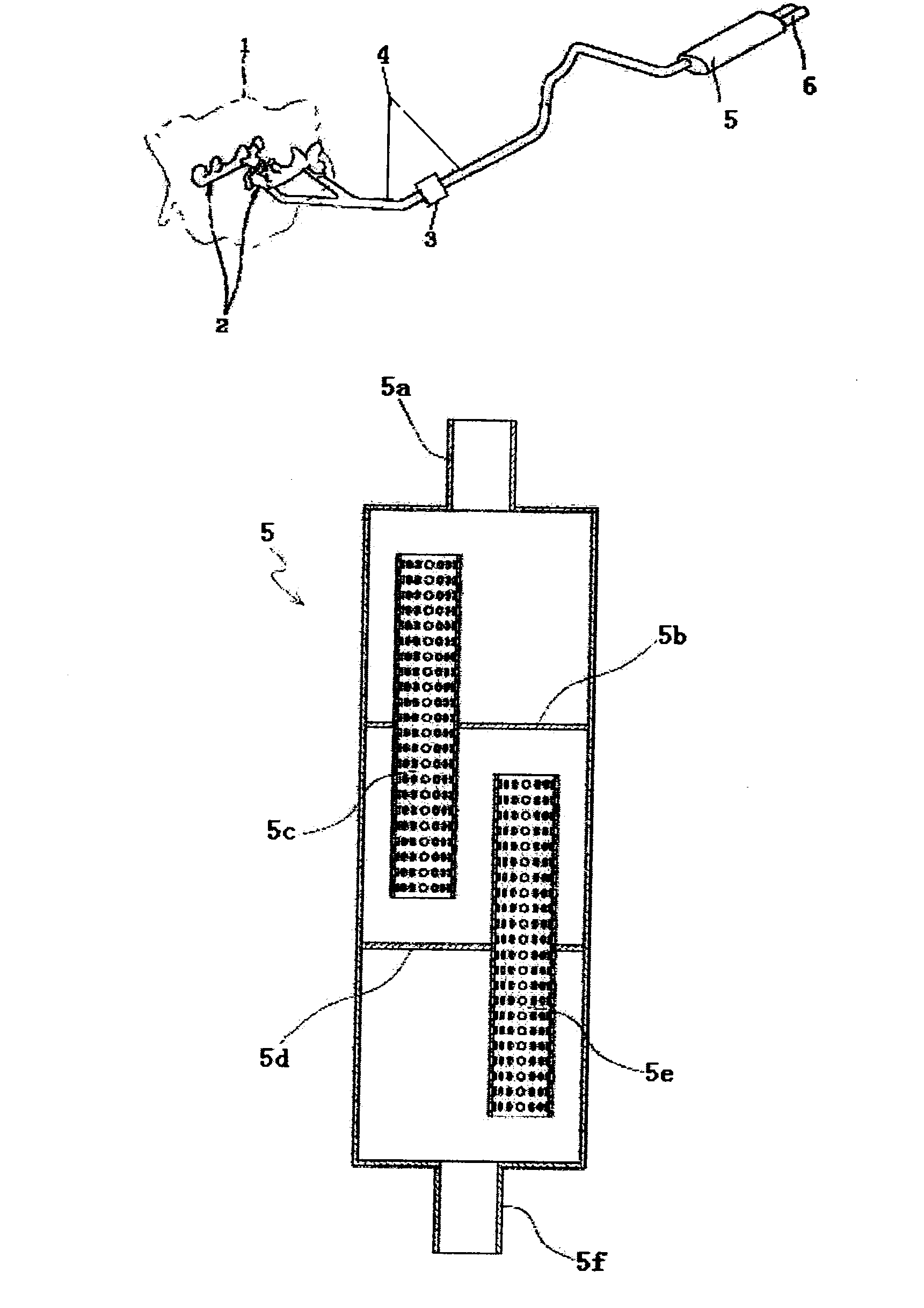

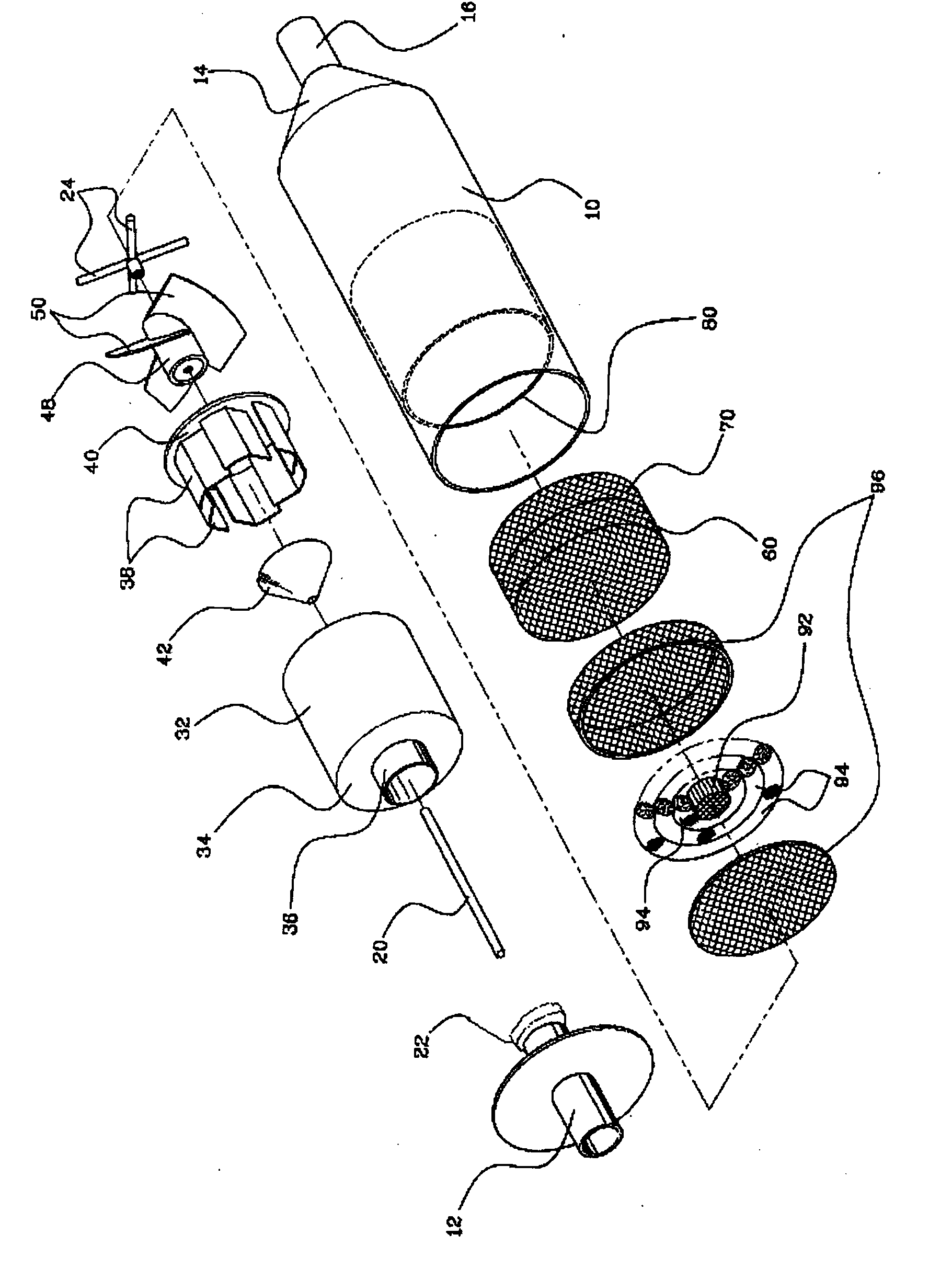

[0040] Figure 2 to Figure 4 An exemplary diagram of the vehicle muffler of the present invention is shown. figure 1 The current muffler shown, figure 2 Shown is an exploded perspective view of the vehicle muffler of the present invention, image 3 Shown is the sectional view of the use state of the vehicle muffler of the present invention, Figure 4 The rotating state of the rotary plate of the vehicle muffler of the present invention is shown.

[0041] As shown in the above figure, the vehicle muffler 100 of the present invention includes: a box body 10 , a fixed shaft 20 , a rotating body 30 , an aluminum mesh 60 , a copper mesh 70 , a static electricity generating part 80 , and a cleaning part 90 .

[0042] The box body 10 is a cylindrical structure with an internal space. One end of the box body 10 is connected to the tubular ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com