Method for monitoring temperature of annealing machine bench

A technology for monitoring temperature and annealing, which is applied to electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] When the semiconductor process enters the process below 0.18 micron, cobalt silicide (Co Salicide) is widely used as a new type of metal silicide. The biggest difference from Ti Salicide is that the annealing temperature of Co Salicide is lower, between 500°C and 900°C, and this temperature range belongs to the category of low temperature control for rapid annealing machines. Co Salicide undergoes a phase transition (from high-resistance phase CoSi to low-resistance phase CoSi 2 ) temperature range is 550°C to 610°C, so the sheet resistance of the cobalt silicide layer will vary greatly, that is, the sheet resistance of the cobalt silicide layer is very sensitive to the annealing temperature in this range. Among them, the center temperature of the phase transition temperature range of Co Salicide is 570°C.

[0024] A method for monitoring the temperature of an annealing machine, comprising the following steps:

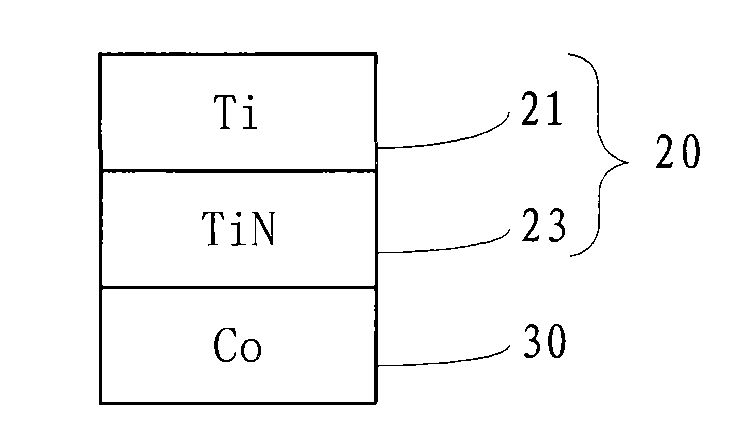

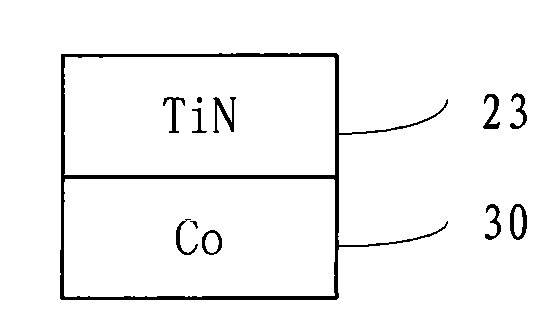

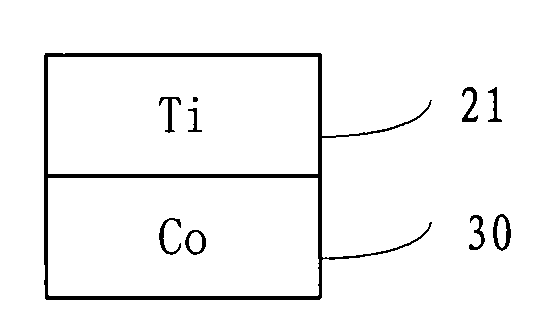

[0025] (1) Depositing a cobalt (Co) metal layer and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com