Permanent-magnet motor capable of effectively eliminating slot effect

A permanent magnet motor and permanent magnet technology, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, and the shape/style/structure of the magnetic circuit. Electrical performance and other issues, to achieve uniform distribution of cogging magnetic field, reduce yoke reluctance, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

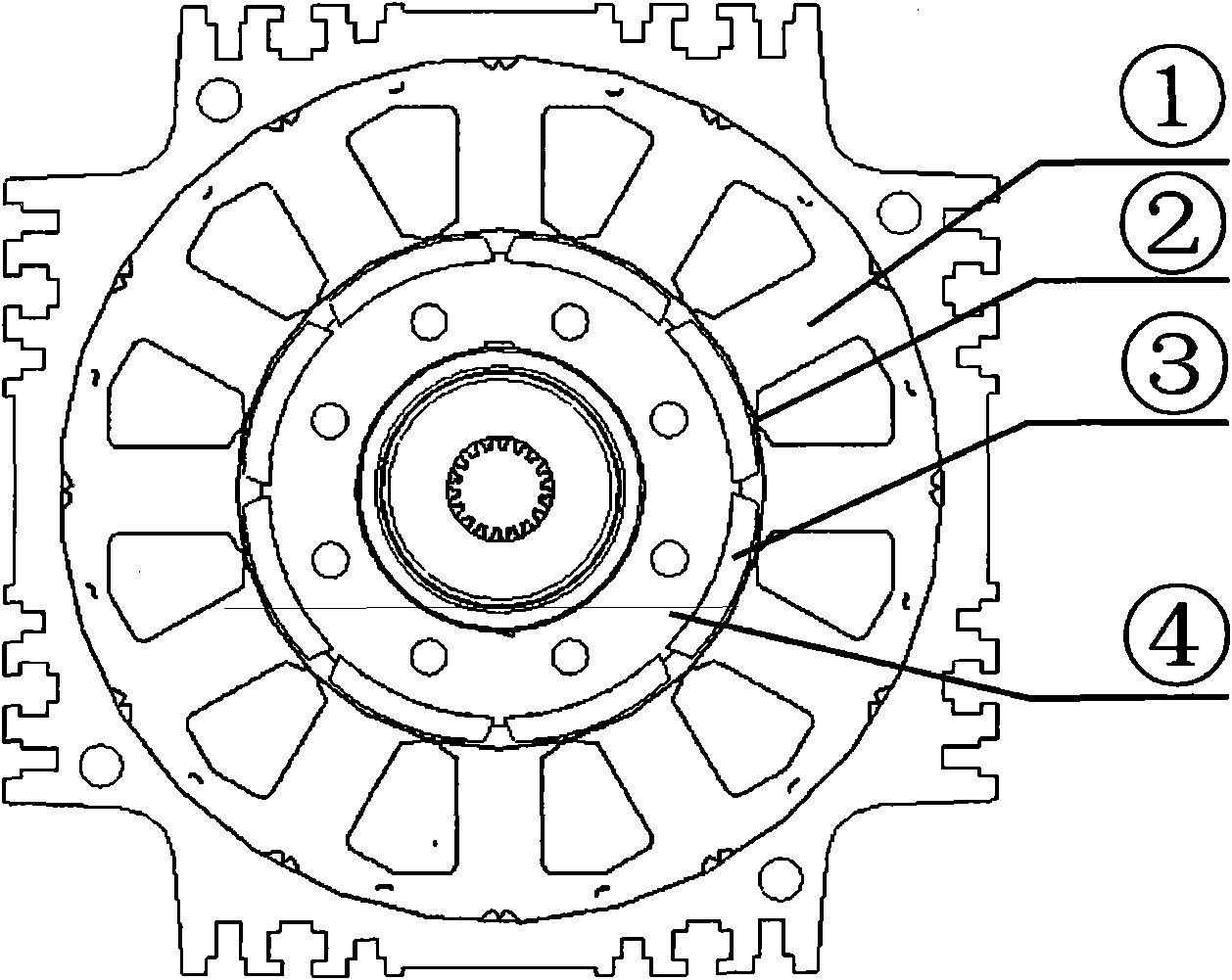

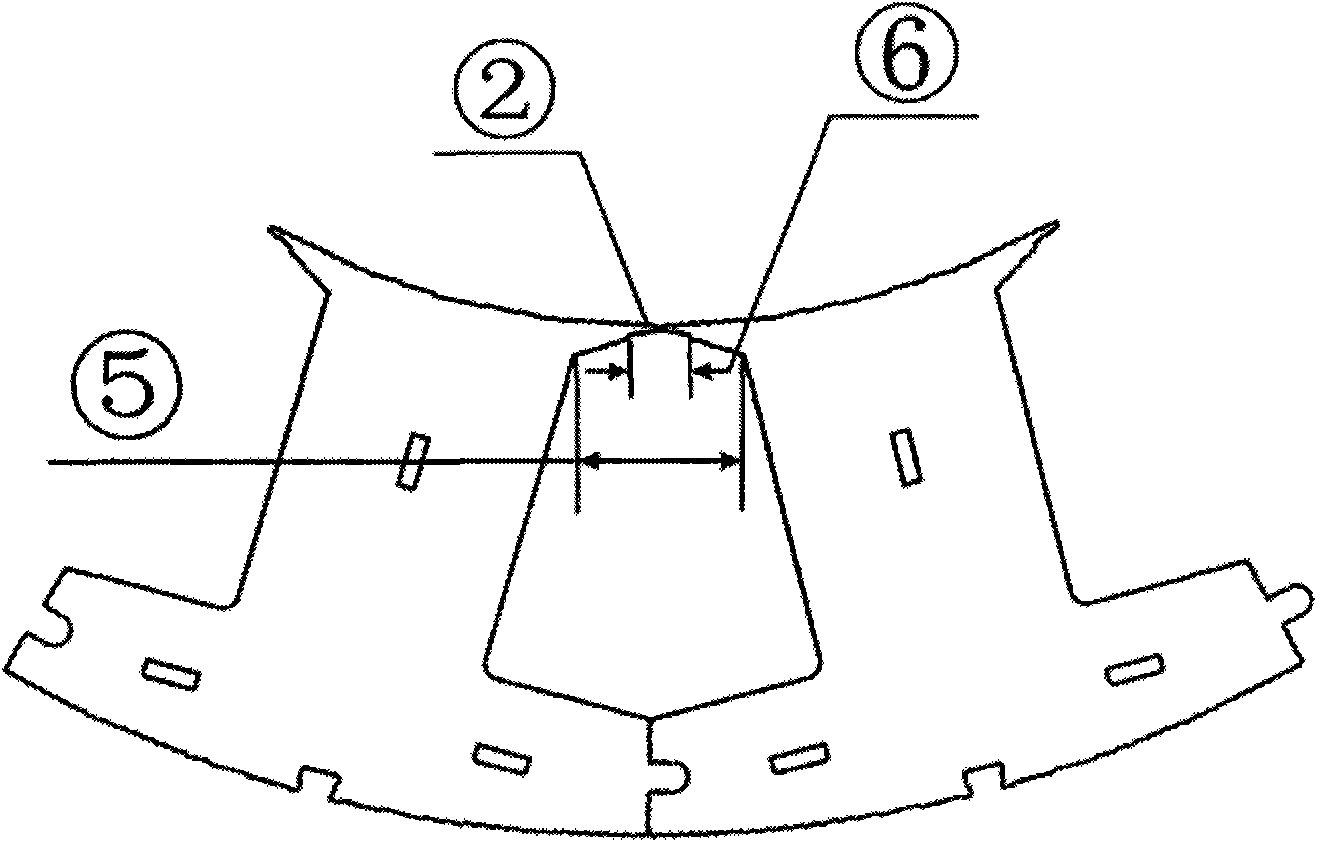

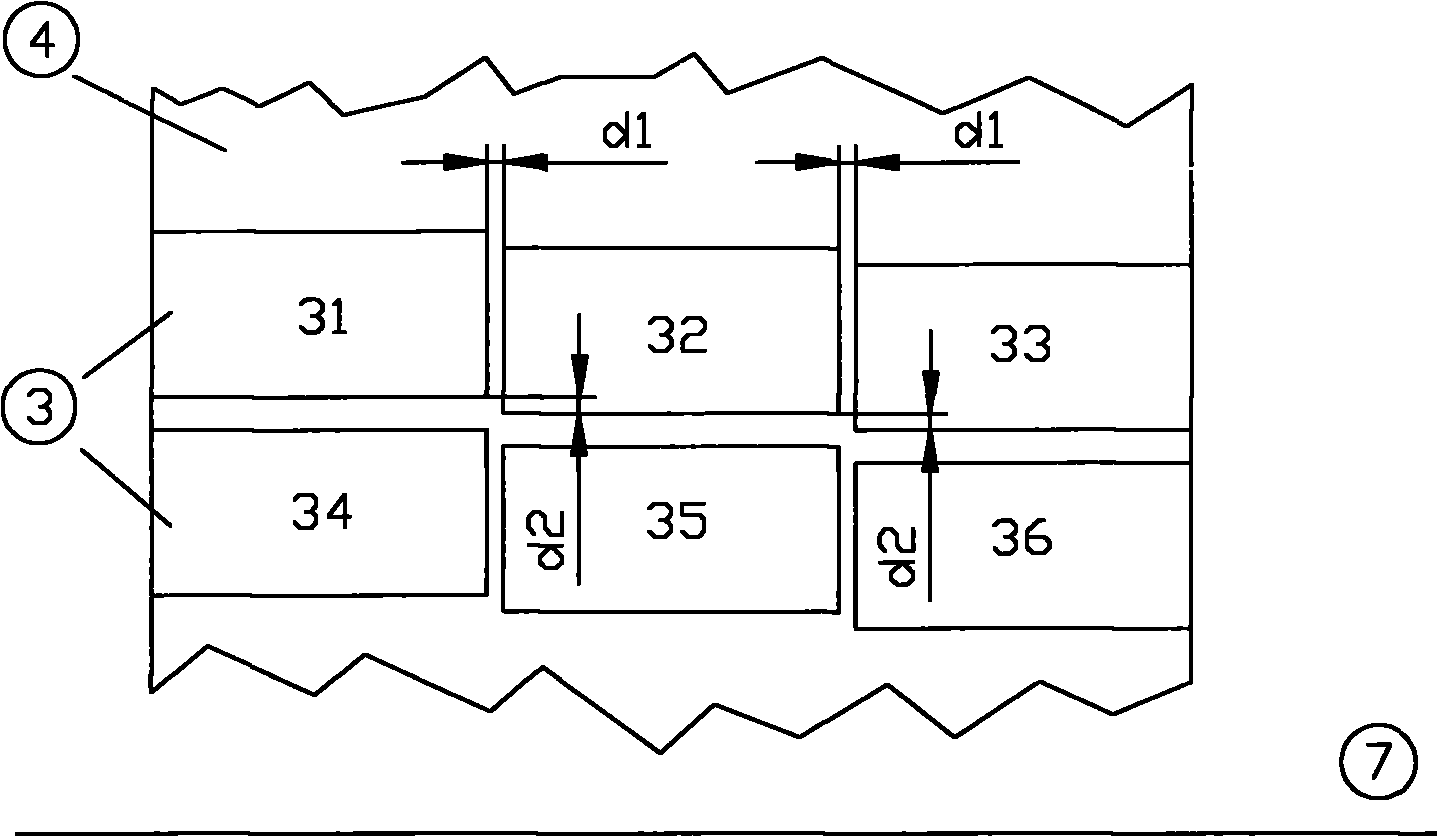

[0027] Such as Figure 1-4 Shown: ① is the stator, ② is the tip of the shoe, ③ is the permanent magnet, ④ is the rotor, ⑤ is the tooth groove, and ⑥ is the notch.

[0028] see figure 1 , is a structural schematic diagram of the permanent magnet motor of the present invention. The permanent magnet motor in this embodiment has 8 poles, and the surface of the permanent magnet ③ is attached to the surface of the rotor ④. The stator of the permanent magnet motor is composed of 12 stator blocks ①, and 12 stators The pieces ① are interlocked together to form a circular outer stator, and the boot tips ② of two adjacent stators are in close contact.

[0029] see figure 2 , is an enlarged schematic diagram of the stator part of the permanent magnet motor of the present invention. Two adjacent stators are firmly spliced through the semicircular grooves on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com