Preparation method and low-temperature continuous stirring ultrafiltration device for anti-tumor and anti-infection allicin injection

A technology of allicin and injection, which is applied in the direction of antineoplastic drugs, devices for making drugs into special physical or taking forms, biochemical equipment and methods, and can solve the problem of low alliin or allicin content, etc. problem, to achieve the effect of reducing decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

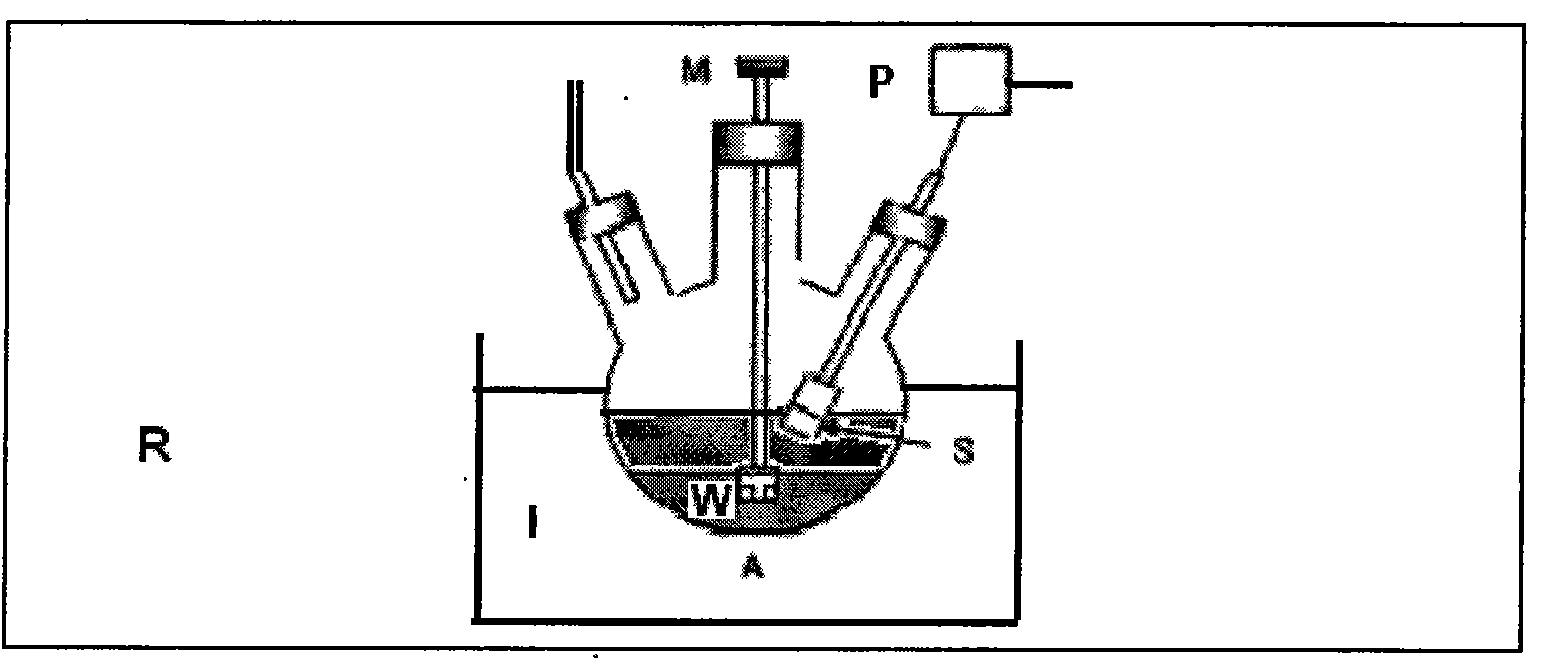

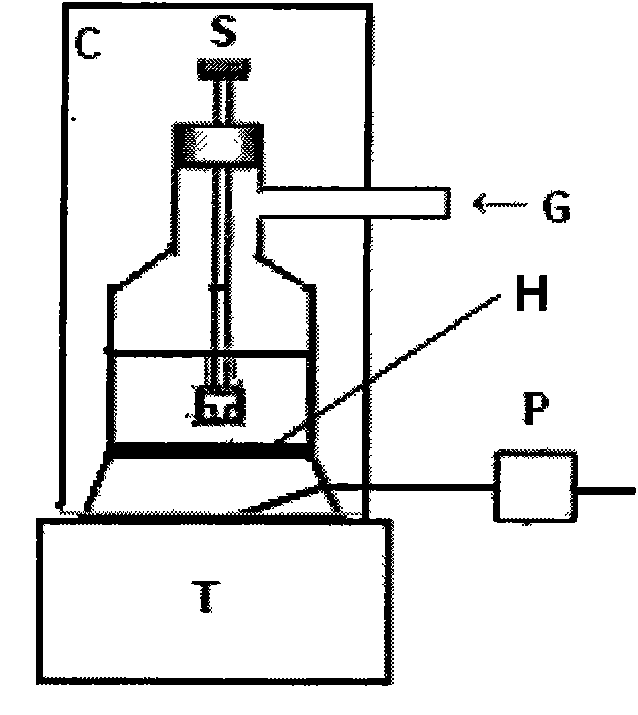

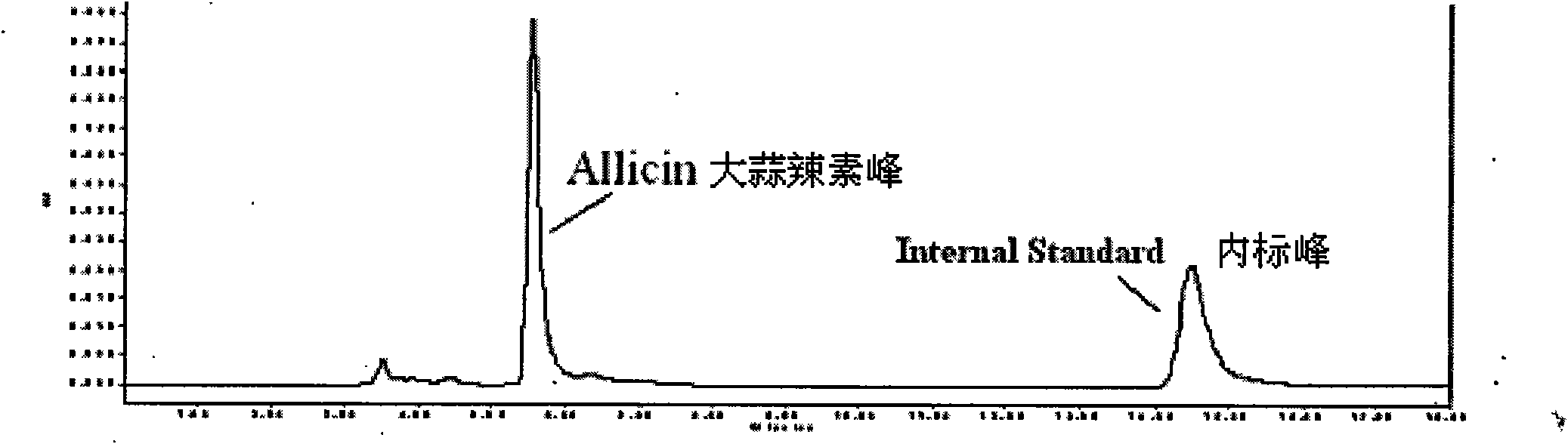

[0049] Figure 1-3 For the embodiment schematic diagram of the present invention, the preparation method of allicin injection is as follows:

[0050] (1) Add about 1000-2000ml of deoxygenated pure water to a 5000ml rigid three-necked bottle A, add 35.4g of allinase, and stir (M, 60rpm) to dissolve. Adjust the temperature of water bath I to 25-35°C, and check that the pH is 6.5-8.5.

[0051] (2) Put about 500-1000ml of deoxygenated pure water in a closed graduated separatory funnel, add a specified amount of alliin 35.4g, and shake gently to dissolve. High-purity nitrogen or argon fills the G space of the three-neck flask.

[0052] (3) Under continuous stirring (M, 60rpm), the alliin solution enters the three-necked bottle A through the closed graduated separatory funnel through the B port at a speed of about 50ml / min. Continue to stir for 10 minutes after the dropwise addition, and the total reaction time is about 30 minutes. An enzymolysis reaction solution containing all...

Embodiment 2

[0057] The preparation method of allicin injection is as follows:

[0058] (1), add deoxygenated pure water and allinase in the container, wherein deoxygenated pure water: allinase=1000ml: 35.4g, fully stir to fully dissolve allinase, the stirring speed is 60rpm, adjust the water bath temperature to 25°C, Control the pH value within the range of 6.5, and the allinase activity is greater than 1000IU / g; the deoxygenated pure water is freshly boiled and cooled pure water, and high-purity nitrogen or argon gas is injected into the bottom for 1 hour / 10L to remove the dissolved oxygen.

[0059] (2), prepare alliin solution, wherein alliin: deoxygenated pure water = 35.4: 500ml, slowly drop the alliin solution into the above container, wherein alliin: allinase = 1mg: 1IU, fully stir, The stirring speed is 60rpm, and argon or high-purity nitrogen is continuously introduced to fill the container with high-purity nitrogen or argon; the purity of alliin is greater than 90%;

[0060] (3...

Embodiment 3

[0066] (1), add deoxygenated pure water and allinase in the container, wherein deoxygenated pure water: allinase=2000ml: 35.4g, fully stir to make allinase fully dissolve, the stirring speed is 120rpm, adjust the water bath temperature to 35°C, Control the pH value within the range of 8.5, and the allinase activity is greater than 1000IU / g; the deoxygenated pure water is freshly boiled and cooled pure water, and high-purity nitrogen or argon gas is passed into the bottom for 1 hour / 10L to remove the dissolved oxygen.

[0067] (2), prepare alliin solution, wherein alliin: deoxygenated pure water = 35.4: 1000ml, slowly drop the alliin solution into the above container, wherein alliin: allinase = 1mg: 2IU, fully stir, The stirring speed is 60rpm, and argon or high-purity nitrogen is continuously introduced to fill the container with high-purity nitrogen or argon; the purity of alliin is greater than 90%;

[0068] (3), continue to stir after dropwise addition, total reaction time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com