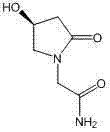

Preparation method of (S)-4-hydroxy-2-oxo-1-pyrrolidine acetamide

A technology of pyrrolidine acetamide and oxo substitution, which is applied in the direction of organic chemistry, can solve the problems of high cost, failure to produce products, and difficulty in recycling, and achieve the effects of short reaction cycle, increased yield, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A kind of preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide, its concrete steps are:

[0077] (a) Put 518.4g of glycinamide hydrochloride, 394g of sodium bicarbonate and 3.7L of absolute ethanol into a three-necked reaction flask, control the pH value to about 7.4, and heat up to reflux under stirring;

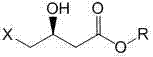

[0078] (b) After reflux for 2 hours, gradually add 781.6 g of (S)-4-chloro-3-hydroxybutyric acid ethyl ester dropwise, in the process of dropping, add the remaining sodium bicarbonate 394 g in 8 batches, and pass the pH value Check and control the amount of alkali added each time to ensure that the pH value of the reaction≤8.5;

[0079] (c) After (S)-4-halo-3-hydroxybutyrate was added dropwise, the reaction was refluxed for 24 hours, and the product (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide was determined by HPLC When the content is 75%, the reaction is terminated, and the obtained solution is hot filtered and concentrated to obtain the crude product ...

Embodiment 2

[0083] A kind of preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide, its concrete steps are:

[0084] (a) Put 28.50 g of glycinamide hydrochloride, 20.65 g of sodium bicarbonate and 200 ml of absolute ethanol into a three-necked reaction flask, control the pH value to about 7.4, and heat up to reflux under stirring;

[0085](b) After 2 hours of reflux, 39.08 g of (S)-4-chloro-3-hydroxybutyric acid ethyl ester was gradually added dropwise. During the dropwise addition, 20.65 g of the remaining sodium bicarbonate was added in 5 batches, and the pH value was passed. Check the amount of alkali added each time to ensure that the pH value of the reaction≤8.5;

[0086] (c) After (S)-4-halo-3-hydroxybutyrate was added dropwise, the reaction was refluxed for 24 hours, and the product (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide was determined by HPLC When the content was 74%, the reaction was terminated, and the obtained solution was concentrated by hot filtration to obt...

Embodiment 3

[0090] A kind of preparation method of (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide, its concrete steps are:

[0091] (a) Put 277.1g of glycinamide hydrochloride, 210.6g of sodium bicarbonate and 2000ml of absolute ethanol into a three-necked reaction flask, control the pH value to about 7.4, and heat up to reflux under stirring;

[0092] (b) After reflux for 2 hours, gradually add 417.8 g of (S)-4-chloro-3-hydroxybutyric acid ethyl ester dropwise. During the dropwise addition, add the remaining sodium bicarbonate 210.6 g in 8 batches, and pass the pH value Check the amount of alkali added each time to ensure that the pH value of the reaction≤8.5;

[0093] (c) After (S)-4-halo-3-hydroxybutyrate was added dropwise, the reaction was refluxed for 24 hours, and the product (S)-4-hydroxyl-2-oxo-1-pyrrolidineacetamide was determined by HPLC When the content was 72%, the reaction was terminated, and the obtained solution was concentrated by hot filtration to obtain the crude product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com