Method for testing dynamic phase transition of steel

A test method and phase change technology, which is applied in the investigation stage/state change, measuring device, and analysis of materials, etc., can solve the problems of lack of test methods, heavy workload of metallographic and sampling methods, and high cost of resistance methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

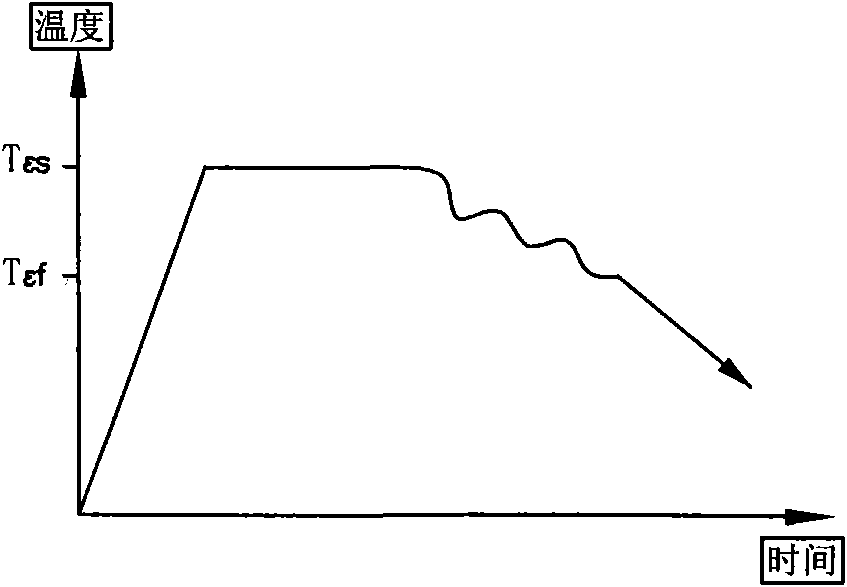

[0022] In the steel material dynamic phase change test method of the present embodiment, the selected size is a steel block of 20mm × 15mm × 10mm as sample one, and the material is Q345C; test equipment such as figure 1 As shown, the specific test steps are:

[0023] 1) Heat the sample to the austenite zone (T εs 1000℃), and keep warm for 5 minutes;

[0024] 2) Then on the thermal simulation test machine with 1×10 -3 / s deformation speed constant speed compression sample 1, the degree of deformation is 20%, the deformation end temperature (T εf ,) is 545°C;

[0025] 3) Stress values and temperature values in the entire compression deformation process in the above-mentioned 2) step are collected on the thermal simulation testing machine, and 310 stress values and temperature value data are collected;

[0026] 4) According to the process data of temperature and stress collected in the above testing process, use Origin data processing software (data analysis and drawin...

Embodiment 2

[0029] The steel dynamic phase change test method of the present embodiment is basically the same as that of the first embodiment, the difference is: 1, the selected size is Φ10mm×15mm round steel as the second sample, and the material is SPA-H; 2, the first) step The heating rate in is 5 ℃ / s, and holding time is 7 minutes; 3, the degree of deformation in the 2nd) step is 50%, and deformation end temperature (T εf ) is 530° C.; 4. There are 350 stress and temperature data collected in step 2).

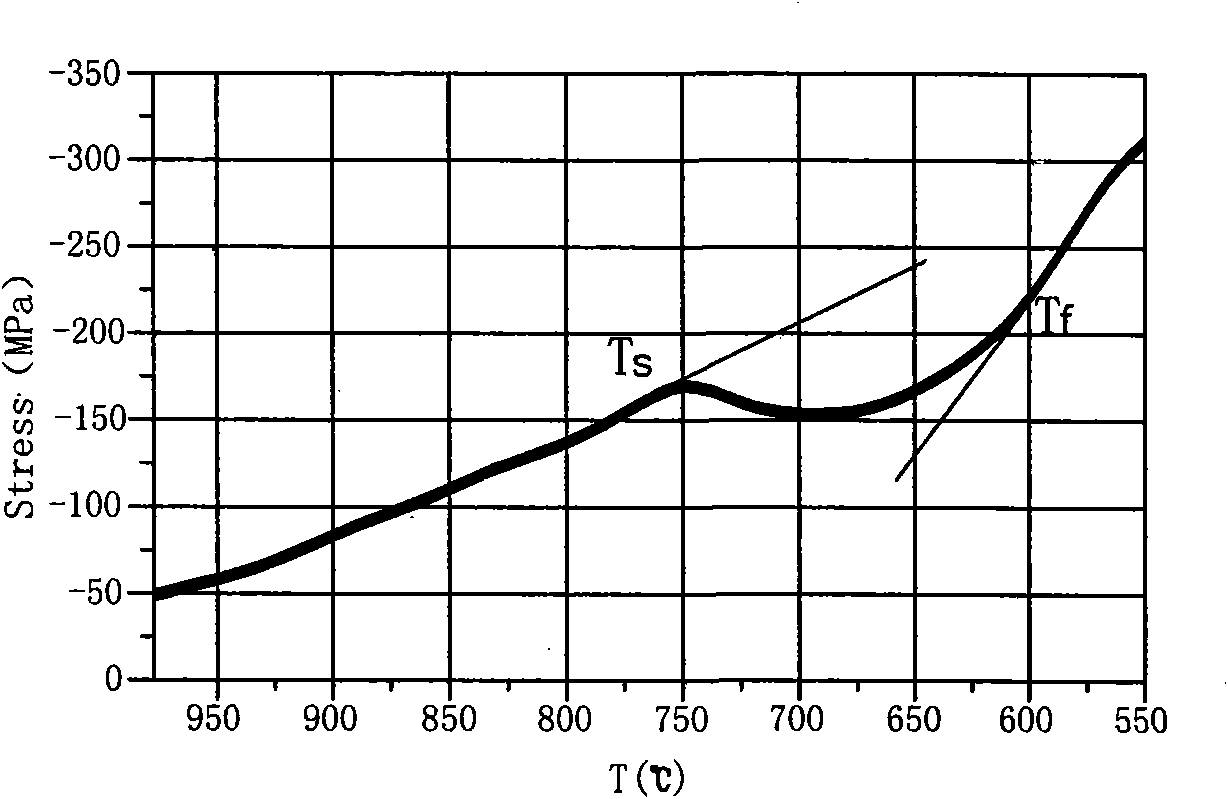

[0030] The temperature-stress change curve that present embodiment draws is as follows image 3 shown by image 3 It can be clearly seen that the change of stress with temperature deviates from the original linear track when the sample starts at 802.12°C, and when the temperature drops below 628.91°C, the change of stress with temperature tends to be linear again, so it can be determined that the steel The austenite transformation start temperature and the austenite transformation en...

Embodiment 3

[0032] The steel dynamic phase change test method of the present embodiment is basically the same as that of the first embodiment, the difference is: 1. The selected size is Φ8mm×12mm round steel as the third sample, and the material is J55; 2. In the 1st) step The heating rate is 18°C / s, and the holding time is 15 minutes; 3, the degree of deformation in the 2nd) step is 35%, and the deformation end temperature (T εf ) is 540°C; 4. There are 330 stress and temperature data collected in step 2).

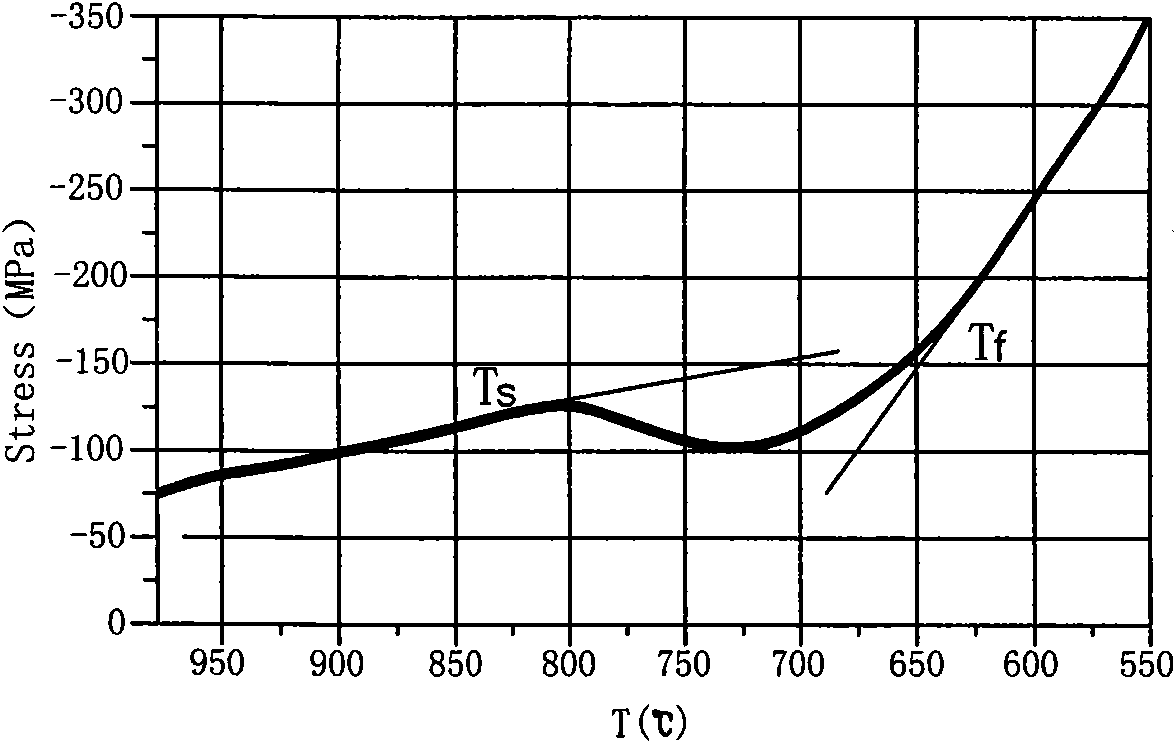

[0033] The temperature-stress change curve that present embodiment draws is as follows Figure 4 shown by Figure 4 It can be clearly seen that the change of stress with temperature deviates from the original linear track when the sample starts at 763.95°C, and when the temperature drops below 598.03°C, the change of stress with temperature tends to be linear again, so it can be determined that the steel The starting temperature of austenite transformation and the end temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com