Synchronous heat exchange gas absorption tower and nitric oxide absorption and concentration process

A technology of gas absorption and nitrogen oxides, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as increased power consumption and operating costs, uncontrollable reaction rate, uneven absorption efficiency, etc., to achieve governance Good effect, improved reaction and absorption efficiency, and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

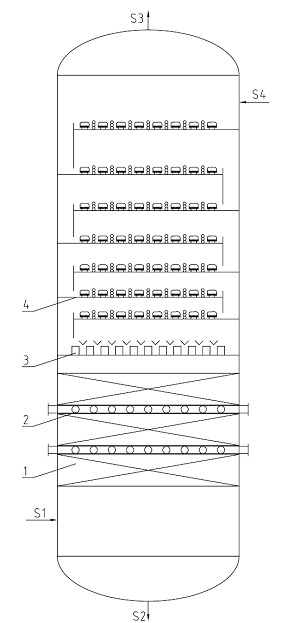

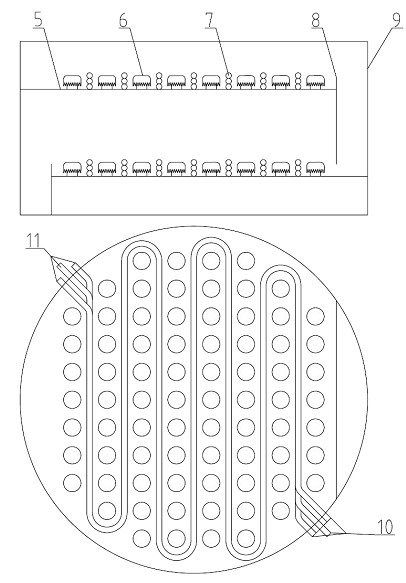

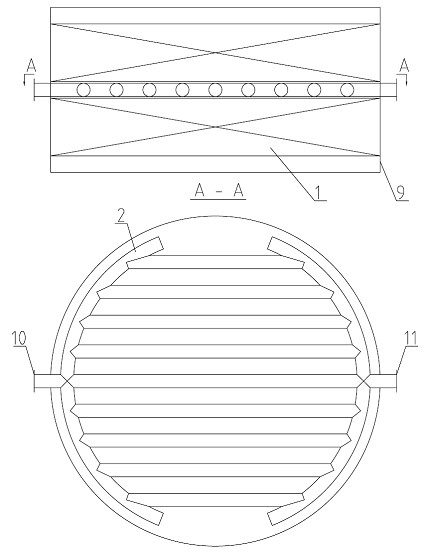

Embodiment 1

[0032] Embodiment 1: adopt 40% nitric acid to make oxidizing agent to produce adipic acid product, produce NO X Exhaust gas, flow rate 5000Nm 3 / h, NO X The average mass concentration of 25%, of which NO and NO 2 About 2:1. The exhaust gas and air are mixed at a volume ratio of 2:1 and then enter the absorption tower, and dilute nitric acid wastewater with a mass concentration of 1.5% is used as an absorbent. The operating pressure of the absorption tower is 4.2atm, and 50 layers of composite bubble-cap trays with heat exchange coils are used inside for absorption. 10 upper trays, 1 row of coils between the tray bubble caps, with a plate spacing of 0.8m; 15 middle trays, 2 rows of coils, with a plate spacing of 0.6m; 25 lower trays, 3 rows of coils, and a plate spacing 0.5m. The diameter of the absorption tower is 2.4m. NO in exhaust gas X The emission concentration is 134ppm, and the rate is 0.78kg / h. Nitric acid with a mass concentration of 40% flows out from the abs...

Embodiment 2

[0033] Implementation example 2: adopt 55% nitric acid to make oxidant to produce methanol catalyst, produce NO and NO 2 Gas, the ratio is about 1:1, the flow rate is 500Nm 3 / h. The operating pressure of the absorption tower is 8atm, and the top adopts 30 layers of composite bubble-cap trays with heat exchange coils for absorption. There are 2 sections of packing at the bottom of the tower, and 350Y-type structured packing is used above 4m, and the height of each tray is 200mm. There is a heat exchange coil; the bottom is filled with a 38mm saddle ring with 2m, and no heat exchange coil is provided. The exhaust gas and air are mixed in a volume ratio of 1:2, and then enter the absorption tower from the middle of the two packings, that is, below the structured packing, and another stream of air (with NO X Gas volume ratio 1:1) enters the absorption tower from the bottom of the tower, that is, below the saddle ring packing, and is used for bleaching high-concentration nitric ...

Embodiment 3

[0034] Implementation Example 3: Adopt 50% nitric acid to make oxidant to produce oxalic acid, produce NO and NO containing 50% 2 Gas, flow rate 1500m 3 / h. The waste gas and air are mixed at a volume ratio of 1:2.5 and then enter the absorption tower. The operating pressure of the absorption tower is 6.8 atm, and the absorbent is clean water. The top adopts 30 layers of composite bubble-cap trays with heat exchange coils for absorption. There is a section of packing at the bottom of the tower, which uses 500Y structured packing of 3m, and the height of each plate is 200mm. There are heat exchange coils between each plate. In the tray section, there are 9 trays in the upper part, 1 row of coils between the bubble caps of the trays, with a plate spacing of 0.5m; 16 trays in the middle, 2 rows of coils, and a plate spacing of 0.45m; 15 lower trays, 3 rows of coils , The board spacing is 0.4m. The diameter of the absorption tower is 1.6m. NO in exhaust gas X The discharge co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com